59. Flippers, Bumpers, and Slingshots

Real pinball machines are mechanical contraptions with lots of moving

parts. It's what makes them stand apart from just about every other

kind of arcade game. When you translate pinball into a video game,

you lose that physicality. In a virtual pin cab, you can bring back

some of the mechanical feel of the real thing by adding similar moving

parts that can be actuated in sync with the game action.

The moving parts on a real machine that produce most of the tactile

experience for the player are the ones controlled by solenoids:

flippers, slingshots, bumpers, kickers. All of these are driven by

powerful magnetic coils that propel the metal parts at high speed.

The kick of the solenoids is palpable while playing. This chapter is

about reproducing that tactile solenoid effect in a virtual cab.

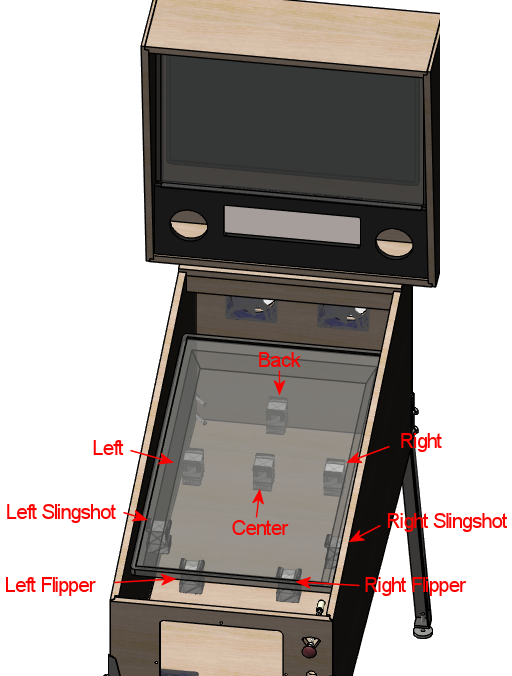

How many? Where do they go?

It's up to you which devices to include in your setup. The common

setups, which DOF supports most readily, use two devices to simulate

flippers, two to simulate slingshots, and four to six devices to

simulate pop bumpers.

Flippers: The most basic solenoid setup uses just two

solenoids, one for each flipper. These should be positioned near the

location where the actual flippers appear in the video presentation,

near the bottom of the TV. You can mount these inset a bit from the

sides of the cabinet, where the actual flipper solenoids would be on a

real machine, or you can mount them directly to the cabinet walls. If

you're using slingshot solenoids in addition to the flippers, you

might want to use the inset positioning for the flippers, and position

the slings further apart, to make the sounds more noticeably separated

in space.

Slingshots: These go just behind the flipper devices. Most

people mount these directly to the side walls of the cabinet, since

real slingshots are also close to the walls.

Bumpers: There are two common configurations for bumpers.

The "deluxe" arrangement uses six devices, arranged as a row of

three across roughly the middle of the playfield TV, and a second

row of three closer to the rear of the TV. This provides devices

at enough different places that DOF can do a good job of placing

each sound effect close to its simulated origin in the game.

The other common arrangement uses a single row of three across

the middle of the TV, and one more near the rear center.

DOF refers to these two common bumper configurations as "10-Bumper"

and "8-Bumper" setups. That's a bit confusing, because it doesn't

really mean bumpers. In both cases, two of the devices

are flippers and two are slingshots. So what DOF really means

is "10-Solenoid" and "8-Solenoid".

Here's what the two arrangements typically look like in a cab.

"10-Bumper" placement. The actual "bumpers" are

the six devices across the middle and back playfield area.

The two devices at the front are the flippers,

and the two just behind those are the slingshots.

"8-Bumper" placement. The actual "bumpers" are

the four devices across the middle and back playfield area.

The flipper and slingshot devices are the same as in the

"10-Bumper" layout.

Parts

The most effective way to reproduce the sensory effects of a pinball

solenoid is to use some of kind of solenoid.

In a real pinball machine, they have to use a specific mechanism for

each job, because each mechanism has to do the actual work of

propelling the ball (or whatever it's meant to do). In a virtual cab,

we don't have that constraint. Our devices don't have to actually do

anything physical in the game; they just have to produce the right

sensory impression. So we're free to substitute anything that sounds

and feels similar. That opens up our options and lets us consider

other properties when we're selecting devices, such as cost, size,

durability, and power needs.

If you open up the field to consider anything with a solenoid in it,

you have an overwhelming number of options. Fortunately, people have

been building pin cabs for long enough now that a few winning options

have emerged, so you won't have to spend months doing research on

this; you can just pick one of the common solutions below. Like most

pin cab features, everything has some tradeoffs, so there's not a

perfect one-size-fits-all solution. We'll give you the pros and cons

of each to help you decide.

Note that you don't have to settle on a single device type! Many pin

cab builders do use one device type for everything, but others think

it's a plus to use different devices for different roles, so that each

type of device sounds a little different. For example, you might use

the Siemens contactors for the flippers, and starter relays for the

bumpers and slingshots.

Contactors

A contactor is a type of electrically controlled switch used in

high-power applications, such as controlling industrial equipment or

large appliances like air conditioners. "Contactor" is just

another word for "relay" - they're fundamentally the same thing - but

they call it a contactor when it's the higher power type.

On the inside, a contactor is a mechanical switch controlled by a

solenoid. The solenoid moves a set of mechanical switch blades when

energized. Because of the high power that a contactor is designed to

handle, the switch blades have to be hefty, and they have to move

across a wide gap when switching.

It's that big moving switch element that makes contactors useful for

our purposes. The large moving parts make a nice "thunk" when the

device switches on and off, strong enough to resemble a pinball

flipper, slingshot, or bumper.

What to buy: The type of contactor that's popular with pin cab

builders is made by Siemens. One particular known quantity that many

cab builders use is Siemens model number 3RH1140-1BB40 (pictured at

right). It's safest to look for that exact part, but Siemens makes a

large number of similar devices, and I suspect that any Siemens model

that physically resembles this one will have substantially the same

component parts inside and will produce similar sensory effects.

What to buy: The type of contactor that's popular with pin cab

builders is made by Siemens. One particular known quantity that many

cab builders use is Siemens model number 3RH1140-1BB40 (pictured at

right). It's safest to look for that exact part, but Siemens makes a

large number of similar devices, and I suspect that any Siemens model

that physically resembles this one will have substantially the same

component parts inside and will produce similar sensory effects.

Many other types of contactors are also available from other

manufacturers, so there are undoubtedly many more options out there

that would work. However, there's no reason to assume that any random

contactor would sound "right". If you're considering another device,

ask in the forums to see if anyone else has tried it; or try it

yourself if you want to be a pioneer, but ideally buy it from someone

who will let you return it if it doesn't do the job.

Cost: You can buy these devices new, but you shouldn't:

they're $50 and up apiece new. Given the performance tradeoffs,

they're not worth the money; if you have that kind of budget,

real pinball parts would be a far better investment. So you should

instead buy them used on eBay, where they can be found for about $10

apiece. You might have to be patient to find them at a reasonable

price, since they seem to be a fairly low-volume item on eBay.

Power supply: The Siemens contactors require 24VDC power.

That's not available from a computer ATX power supply, so you'll need

a separate power dedicated 24V supply. See Power Supplies for Feedback

for advice.

The Siemens contactors draw about 400mA each. I'd plan on sufficient

power for three or four of them to fire simultaneously, so be sure

your 24V power supply is rated for at least 2A (equivalent to 48W).

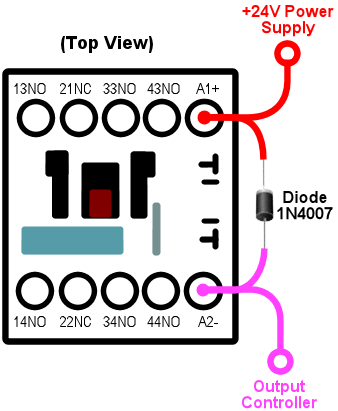

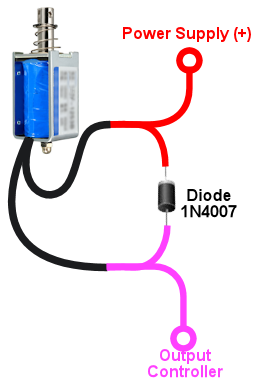

Wiring: Here's how to hook up the typical Siemens contactors:

Note that most of the terminals on the contactor are left unconnected.

The other terminals are all intended to be wired to whatever circuits

the contactor is controlling, but in our case, we don't control

anything at all with the contactor. It's just there for the sound

effect it makes when it switches on and off, so we only connect

the terminals that control its coil, typically A1 and A2 on the

Siemens devices.

The diode is required to protect the output controller and computer

electronics from noise from the magnetic coil inside the contactor.

See Coil Diodes. The stripe on the diode must connect to the

positive (+) power side.

Pros: The biggest "pro" with contactors is that they're happy

to be left in the "on" position indefinitely. That's not at all true

of most solenoids: most solenoids will overheat if left on for long

periods, and many can only tolerate a couple of seconds at a time.

For simulating flippers, the ability to stay on for long periods is

critical, because the player could hold the flipper button

indefinitely to trap a ball.

The tonal quality of audio/tactile effect of the Siemens contactors is

another plus. It's a nice solid mechanical "thunk" that creates the

impression of a large device.

Other good features: they're compact, self-contained, easy to install,

run on fairly low DC voltages (the Siemens devices referenced above

run on 24VDC), and use relatively little power (about 350mA for the

common Siemens device).

Cons: The biggest negative is that the effect is far weaker

than a real pinball solenoid (even though the tonal quality is good).

Also, they require 24V, which means you have to add an extra power

supply for them. The Siemens devices are pricey, unless you buy them

used, and used ones sometimes have a lot of wear that greatly reduces

the strength of the "thunk" effect, which is the whole point for our

purposes. Used ones might not be entirely reliable, either; a couple

of my own Siemens contactors are intermittently "sticky", where

they'll stuck in the on or off position for a while and won't make any

noise. I've heard from other people seeing the same problem.

Recommendation: The Siemens contactors are a popular way to

implement the simulated flippers and other solenoids because they're

simple to install and they won't overheat if left activated for long

intervals. The tolerance for long activation times makes them especially

attractive for flipper effects. They're the best bet if you want to

keep things simple. But the effect isn't nearly as strong as the real

thing, so if realism is a high priority, look at other options.

Automotive starter solenoid relays

This is another kind of high-power relay, in this case specific to

cars. Starter solenoids are used in automotive engine starting

systems; they switch the high-current connection between the battery

and the big solenoid that cranks the engine when you turn the ignition

key. As such, they have very much the same purpose as contactors -

switching high-power loads through a relay switch - and similar

construction.

Like contactors, these have big moving parts inside that create a nice

"thunk" effect when actuated. The effect is similar in tonal quality

to the Siemens contactors, and it's often quite a bit stronger, but

usually not as strong as real pinball coils.

Starter relays are cheaper and easier to find than the Siemens

contactors. Many types sell for under $10 at auto supply stores,

eBay, Amazon, Wal Mart, and other big retailers. Like the contactors,

they're self-contained and easy to install.

Unlike contactors, these devices will overheat if energized for

extended periods, so they're not ideal for flippers. You might be

able to use them for flippers if you take special precautions, such as

using Flipper Logic (see below).

Overheating is less of a risk when you use these devices for bumpers

and slingshots, since those typically only fire in brief bursts in

normal play.

Reliability is also a concern. If you think about it, these devices

aren't typically fired all that often in their intended application of

starting a car. A pin cab will subject them to much heavier use than

the manufacturers presumably expect (and design for). Some people on

the forums have reported that they need to replace these as frequently

as every few months, which I'd find overly frustrating. But I'm sure

the durability varies a lot according to how you use your cab and

which specific devices you buy.

What to buy: The type most often mentioned on the forums is the

Ford SW3 type (pictured at right). As with the contactors, numerous

other options are available, but this one is a known quantity

that other pin cab builders have found to work well.

What to buy: The type most often mentioned on the forums is the

Ford SW3 type (pictured at right). As with the contactors, numerous

other options are available, but this one is a known quantity

that other pin cab builders have found to work well.

Power supply: Almost every automotive device runs on 12V DC

(but as always, check the product documentation or seller page to

confirm details for the actual product you buy). You can use the 12V

output from your secondary ATX power supply. Note that these devices

place a large load on the power supply - about 6A, or 72W - so make

sure you have a powerful enough 12V supply, and don't connect them to

the same ATX power supply running your computer motherboard. When

calculating power needs, take into account that there will be times

during normal play when several of the devices fire simultaneously, so

multiply the amps/wattage rating by three or four to figure how much

total power you might need. See See Power Supplies for Feedback.

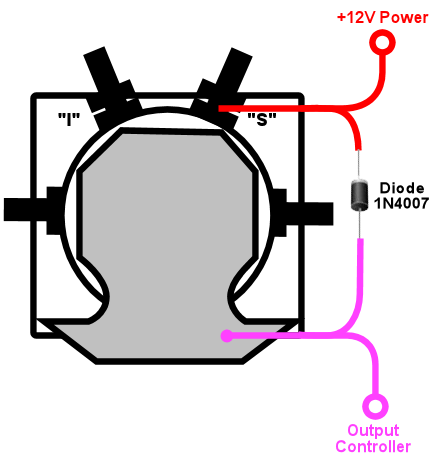

Wiring: For the Ford SW3 type commonly used, the wiring

plan looks like this:

On the Ford SW3 type, you'll find four screw terminals sticking

out from the body of the device. The ones on top (in the orientation

shown above, anyway) should be labeled "S" and "I". The ones sticking

out from the sides aren't typically labeled. In addition, the large

metal plate that looks like a mounting bracket is indeed a mounting

bracket, but it's also the electrical ground connection for the

device. The terminals of interest for pin cab use are the one

labeled "S" and the mounting bracket/ground plate.

If your solenoid isn't labeled like the Ford type above, you'll have

to figure out which terminals are which. On any automotive device,

you can count on any exposed metal on the outside being wired to the

electrical ground, so look for an unpainted mounting plate or a socket

for a mounting bolt. Now get out your multimeter. Set it to measure

resistance. Connect one probe from the meter to the ground point

(that exposed metal or mounting plate or whatever), and use the other

probe to measure the resistance to each of the other terminals, one at

a time. One terminal should have a low but non-zero resistance,

probably something like 3 or 4 ohms. That should be the +12V coil

terminal - the one that corresponds to the "S" terminal on the Ford

devices.

Connect +12V from the secondary ATX power supply to the "S" terminal.

Wire the mounting bracket to an available port on your output

controller.

The diode is required to protect the output controller and computer

electronics from noise from the magnetic coil inside the contactor.

See Coil Diodes. The stripe on the diode must connect to the

positive (+) power side.

These are high-power devices. Do not connect them directly to an

LedWiz output; you'll need some kind of booster circuit or relay with

an LedWiz. If you're using Pinscape expansion boards, you can connect

these directly to any power board port or chime board port.

Pros: Inexpensive, readily available, self-contained, easy to

install, run on 12V DC power. The sound effect they produce has a

good tonal quality, and it's stronger than the Siemens contactors

(though probably weaker than real pinball solenoids).

Cons: They're not designed for continuous activation, so they

shouldn't be used for flippers without special precautions. Some

types might not be durable enough to last more than a few months with

the heavy use they get in a pin cab. For most starter relays, the

effect isn't as powerful as real pinball solenoids.

Recommendation: These are a good choice for everything except

flippers, and they can even be used for flippers if use something like

the Pinscape "Flipper Logic" feature to reduce hold power. Many

people think they sound more realistic than the Siemens contactors.

Durability is the main drawback; some people on the forums have had

to replace them after only a few months. Given their low cost,

though, that might be an acceptable risk, as long as your cab

allows easy maintenance access.

Real pinball mechanisms

If you want maximum realism, you can use real pinball assemblies for

flippers, slingshots, and bumpers.

This is rarely done, but not unheard of. A few cab builders on the

forums have reported going this route. It has a number of challenges

compared to the other methods:

- It's really expensive. The relevant pinball assemblies run about $50 each, so a full set (two flippers, two slings, six bumpers) comes to about $500.

- The assemblies take up a lot of room in the cabinet.

- They require a high-voltage (50V), high power (600W) power supply. That's expensive, and many pin cab builders are uncomfortable working with such hazardous voltages.

What to buy: Buy these at any pinball supplier (Pinball Life,

Marco Specialties). You can also buy them used on eBay, but my

standard warning about used pinball parts on eBay applies: they'll be

beat up and the sellers all think you're an idiot who wants to pay new

prices for old parts. At least price the new ones first so you know

whether an eBay bargain is really a bargain.

The key word when searching the pinball vendors is "assembly":

- "Flipper assembly" (e.g., Williams reference C-13174-L, C-13174-R)

- "Slingshot assembly"

- "Bumper assembly" (e.g., Williams reference A-9415-2, B-9414)

Important note on flippers: Real flipper assemblies from the

1980s and 90s should have "dual coil" arrangements. You won't

actually see two separate coils - the two coils are wound around a

common core and look like a single coil. But you should see three

terminal wires coming out of the coil. The flipper assembly should

have an end-of-stroke switch that diverts power from the high-power

"lift" coil to the low-power "hold" coil when the flipper reaches the

end of its arc.

The dual-coil arrangement makes it safe to hold the flipper button

on for long periods. The lower-power hold coil is specifically

designed for continuous activation without overheating.

I mention all of this because some newer Stern assemblies don't

use the dual-coil design and aren't safe to use in a virtual pin cab

without special software provisions. If you use one of these newer

assemblies, it's critical that use something like the Pinscape Flipper

Logic feature (see below) to

reduce power to the flipper coil when it's held on. Because of this

additional complication, I'd recommend avoiding the Stern assemblies

and using a traditional dual-coil Williams/Bally assembly. That

should be safe to use with any controller without any additional setup

work, since the hold power reduction is handled directly in the

flipper assembly hardware itself.

Cost: About $50 per assembly. A full "10-Bumper" setup (in

DOF parlance - two flippers, two slings, six bumpers) is about $500.

Power supply: Real pinball coils in modern machines require 50V

DC power supplies. Most of them draw 3-5A. To allow for multiple

devices firing at once, you should plan on a minimum 10A (500W)

capacity.

50VDC power supplies are expensive hard to find. It's easier to find

a 48V supply, which will work about as well. 48V supplies are widely

used for LED lighting applications; you can find them in the

500W range on eBay for about $50.

Warning! 50V (or 48V) is a hazardous high voltage that can cause

electric shock. With most of the pin cab output controllers

(including LedWiz and Pinscape), the controller requires you to wire

solenoids so that one terminal is connected directly to the "+" power

supply voltage. This means that +50V is always present at one

terminal of each coil, even when the coils are off. Real

pinball machines have a hard-wired safety interlock switch in the coin

door that cuts off all coil power to the playfield when the coin door

is opened, to protect an operator from shock hazard while working

inside the cabinet. If you install real coils and a 50V supply, I'd

strongly recommend using a similar safety interlock. The switch

should disable the +50V power supply when the door is open.

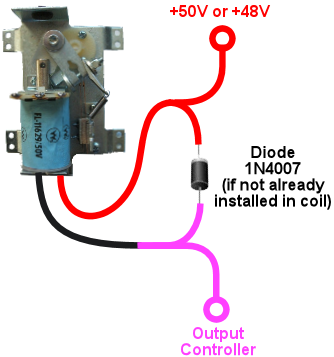

Wiring: Each coil will have two terminals for the power

connections. Connect these following the generic output device wiring

plan (see Feedback Device Wiring).

Many of the flipper, bumper, and kicker assemblies for modern machines

include diodes pre-installed on the coils. If a coil is already

installed, it should have markings for the "+" and "-" wires. This is

often by wire color: red is "+" and black is "-".

If a diode isn't already installed, you must add one. See

Coil Diodes. When a diode isn't present, the coil itself will

be unpolarized, so the order of the wires doesn't matter. Just be

sure that the diode you add is installed with the correct polarity.

If you're using an LedWiz, these devices require some kind of booster

or amplifier, because they use much more power than an LedWiz can

handle. If you're using Pinscape expansion boards, you can connect

these to any Power Board or Chime Board port.

I'd recommend using the Pinscape Chime Boards, if you have them, for the

bumpers and slingshots (but not for the flippers). Those coils

will overheat and melt if they get stuck on by a software fault. If

you don't have any Chime Boards but you're using the Pinscape

software, use the Flipper Logic feature (see

below) to cut off device power if

a port gets stuck on, by setting the "hold power" to 0%.

Pros: Not merely realistic - real.

Cons: Expensive; take up a lot of space; vulnerable to

overheating if they get stuck on; require high-voltage power supply;

electric shock hazard.

Recommendations: The ideal solution, if cost is no object and

you're willing to work with the high voltage.

Open-frame solenoids

The core element of every solenoid-based pinball device is the

solenoid itself, so some cab builders bypass the various devices built

around solenoids (like the contactors and starter relays

mentioned above) and just use standalone solenoids. You

can find options on eBay, and from hobby robotics suppliers like

Adafruit and Sparkfun.

The core element of every solenoid-based pinball device is the

solenoid itself, so some cab builders bypass the various devices built

around solenoids (like the contactors and starter relays

mentioned above) and just use standalone solenoids. You

can find options on eBay, and from hobby robotics suppliers like

Adafruit and Sparkfun.

Plain solenoids don't seem to be widely used on pin cabs, and many of

the people who have tried them seem to be dissatisfied with the

results, judging by the forum discussions on the subject. I think

it's possible to create a good effect with a plain solenoid, but it's

much more challenging than with the pre-made devices like contactors

and starter relays. There are two main reasons for this.

The first is cost. Many pin cab builders who use plain solenoids do

so because they think it's a cheaper way to accomplish these effects.

You can find cheap solenoids, but the cheap ones tend to be small toy

solenoids that aren't nearly as powerful as pinball coils. The

effects they produce will be correspondingly small and unimpressive.

They'll just make metallic clicks. If cost is your main concern,

you're probably going to do better with something like a starter

relay.

The second challenge is that pinball assemblies we're simulating

aren't just big solenoids. They're big solenoids with other

moving parts attached. Typically big, heavy, metal parts. Those

other parts are integral to creating the right sensory effect. If you

want to produce a convincing effect, you'll have to contrive your own

additional moving parts similar to what's in the pinball assemblies. This is what

makes the contactors and starter relays so plug-and-play: they have

their own built-in moving parts that happen to produce effects similar

to what we're after.

I think this can be a promising avenue to pursue, but moreso if you're

willing to buy somewhat more expensive parts and do some

experimentation to find the right combination of attached parts to

produce the right effect.

What to buy: On eBay, look for "open frame solenoid". I'd

avoid the small 12V devices; those are little toy solenoids that will

just sound like metallic clickers. Look for something 24V or above.

Sparkfun sells a 36V solenoid that a couple of people on the forums

have mentioned favorably.

Cost: $5 and up. The Sparkfun 36V device sells for about $20

as of this writing.

Power supply: Varies by device. Check the specs on what

you buy to determine what voltage you need.

If you have to buy an additional power supply, pay attention to the

Volts and Amps required by the device. Make sure the power supply has

a voltage that is the same as the solenoids, and that it provides

at least the required amperage. If you're using multiple

devices of the same type, the power supply will need to provide enough

power for several of the devices simultaneously; I'd multiply the

solenoid amperage by 3x or 4x to get a suitable minimum.

If you see specs in Watts for either the solenoid or power supply, you

can convert between Watts and Amps using this formula:

Watts = Volts × Amps

Wiring: The solenoid should have two wires attached.

Solenoids aren't polarized, so the order of attaching the wires

doesn't matter. Connect one lead to the (+) supply voltage

(use the correct voltage for the solenoid), and connect the

other to your output controller, as shown below.

The diode is required to protect the output controller and computer

electronics from noise from the magnetic coil inside the contactor.

See Coil Diodes. The stripe on the diode must connect to the

positive (+) power side.

Pros: Many options are available; infinite customization

possibilities.

Cons: Sensory effects are less predictable than with contactors

or starter relays; you might have to experiment with several devices

and several mounting styles to get a satisfactory effect. More

complex to set up than contactors or starter relays if you want to

contrive additional moving parts to improve the sound effect. Smaller

devices will produce weak, tinny effects. Most solenoids will

overheat if actuated for more than a couple of seconds at a time, so

special measures (such as Flipper Logic) might be needed, especially

when used for flippers.

Recommendations: If you're thinking of using cheap eBay

solenoids to save money, I'd reconsider: you'll probably be unhappy

with the results and end up replacing them with something better, so

your total cost will be higher than if you just started with something

better. But plain solenoids might work for you if you're willing to

buy more expensive ones with more force, and you're willing to do some

extra work to improvise additional moving parts to simulate the action

of the full pinball assemblies.

DOF setup

In the DOF Config Tool, go to your

Port Assignments page. Find the numbered ports where you wired

your solenoid-type devices. Assign each one to the appropriate

output device.

If you're using a full 10-device setup (see the diagrams above):

- Flipper Left/Right

- 10 Bumper Middle Left/Center/Right or Back Left/Center/Right

- Slingshot Left/Right

If you're using an 8-device setup:

- Flipper Left/Right

- 8 Bumper Left/Center/Right/Back (if you're using an 8-device setup)

- Slingshot Left/Right

"Flipper Logic"

If you're using a Pinscape controller, a special feature is available

to help avoid overheating devices that aren't designed to be activated

for long periods. This isn't necessary with contactors or most real

flipper assemblies, since those are specifically designed to tolerate

continuous activation. It's useful for almost everything else: all

other standard pinball coils, automotive starter relays, and

miscellaneous open-frame solenoids.

The idea behind Flipper Logic is to simulate the way real pinball

machines solve the overheating problem for their flipper coils.

Real flipper coils would have the same overheating issue as our

substitutes if they didn't take special measures. On older pinball

machines, the special measure is that they use two separate coils in

the flipper. A high power "lift" coil provides the initial jolt of

power to flip the flipper and propel the ball, and a low-power "hold"

coil takes over as soon as the flipper is all the way up. (This isn't

obvious looking at them, because the two coils are wound into a single

body. But electrically, there are two coils there.) In the real

machines, an end-of-stroke switch in the flipper mechanism redirects

power from the lift coil to the hold coil.

In some newer Stern machines, they keep the hardware simpler by using

a single high-power coil, and solve the heating problem through

software, by modulating the power using PWM controls. When you press

the flipper button, the software initially applies full power to the

flipper (simulating the "lift coil" power). If you continue to hold

the button for more than a brief time, the software automatically

reduces the power through PWM (simulating the lower "hold coil"

power). The lower power is enough to keep the flipper flipped, but

it's low enough that it won't overheat the coil even if it's held on

for a long time.

Flipper Logic works like the newer Stern machines, reducing the power

to the port after a brief period at full power. This makes it

possible to use more types of devices as a flipper substitutes, by

avoiding the overheating problem common to many solenoids.

You can activate this feature on a port-by-port basis, for any

PWM-capable port. To activate it:

- Run the Pinscape Config Tool

- Go to the Settings page for your controller

- Scroll down to the Output Ports section

- Click the flipper icon (

)

at the right side of the port you want to set up

)

at the right side of the port you want to set up

This lets you enter two parameters: Initial Time and Hold Power. The

Initial Time specifies how long the port receives full power each time

it's activated. You can adjust this from 50ms (1/20 of a second) to

800ms (0.8 seconds) in 50 millisecond increments. The Hold Power is

the PWM power level that's provided to the port after that point, as

long as the port is held on. This can be adjusted from 0% to 100% in

increments of about 7%.

To determine the proper reduced power level for a device, you'll have

to experiment with it. Each device is different. Start at the lowest

non-zero setting. Try the coil: turn it on and leave it on. If it

actuates and then returns to the rest position after about a second,

the power is too low, so try the next higher setting. Repeat until

the device actuates and remains actuated as long as the port is on.

Caution: always monitor the device for heating! Once you find a

setting that's high enough to keep the device actuated, you have to

verify that it's not too high a setting that overheats the

device. It's possible that some devices don't have a safe operating

zone at all - that is, a power level where they'll stay actuated and

won't overheat. You should be able to monitor the device by touch:

if it gets hot to the touch, turn if off immediately, since it's

heating too rapidly and will probably overheat if you leave it on.

If you can leave it on for a couple of minutes without having it

get hot to the touch, it's probably in thermal equilibrium, meaning

it should be safe to leave on in that state indefinitely.

Flipper button feedback control

One question that a lot of new pin cab builders ask on the forums is:

how do I make the flipper buttons control the feedback solenoids for

the flippers? In other words, how do I wire it so that pressing the

flipper buttons activates the flipper solenoids?

There are two ways to go about this. The way that most people do it

these days, which I consider the correct way, is to let DOF handle it.

Happily, this is also the easiest approach, because it doesn't require

any extra wiring or any extra configuration beyond the normal DOF

setup you're going to do anyway.

The older way of handling this, which people did before DOF came

along, was to hard-wire the flipper buttons to the flipper solenoids.

This might seem simpler at first glance than the DOF approach, since

it's just a directly wired connection. But it's actually more

complicated to build! Some extra parts are required because you have

to isolate the higher voltage that the solenoid uses from the low

voltage that the key encoder uses. So DOF takes less work and fewer

parts, assuming you're going to use DOF anyway. The only reason to

use the hard-wired approach is if you're not going to include a DOF

controller.

The thing I particularly like about the DOF approach, apart from

its simplicity, is that it does a better job of simulating

real pinball machines. If you think about how a real pinball machine

works, the flippers only fire when the game allows them to fire - not

between games, not after a TILT condition, etc. If you use the

hard-wired approach, the flipper solenoids will end up firing every

time you press the buttons, so the feedback effects won't always

match the on-screen simulation. With DOF, they'll always match.

The modern way: let DOF handle it

If you're using DOF, you don't have to do any extra

work for flipper effects. Just set up DOF, and the flipper solenoids

will work just like all of the other DOF effects. DOF will take care

of activating the flipper devices whenever the on-screen flippers flip

in a DOF-enabled game. The wiring for the flipper buttons and

solenoids is exactly the same as for every other type of button and

every other type of feedback device: wire the flipper buttons to your

key encoder, just like all of your other buttons, and wire the flipper

solenoids to your output controller, like your other feedback

devices.

If you're trying to picture how the flipper solenoids actually operate

with a DOF setup, here's the sequence of events:

- You press the flipper button, closing its switch

- The flipper button switch signals the key encoder

- The key encoder sends a "Flipper Button Pressed" keyboard event to the computer

- Visual Pinball (or whatever simulator you're using) gets the "Flipper Button Pressed" key event and fires the simulated flipper in the game

- DOF sees the simulated flipper event, and sends a FLIPPER SOLENOID ON command to the output controller

- The output controller activates the output port wired to your flipper solenoid

- The flipper solenoid fires

This approach is better than hard-wiring the solenoid for two reasons.

First, it keeps the wiring simpler. The flipper button switch is only

wired to the key encoder, and the flipper solenoid is only wired to

the output controller - exactly the same wiring as for all of your

other buttons and feedback devices. Second, it allows full software

control over the flipper. That's the way it works on a real machine:

try walking up to a real pinball machine some time and pressing the

flipper button while GAME OVER is showing on the display. Does

anything happen? No, of course not: the flippers are dead when a game

isn't in progress. By wiring the flipper solenoids through the output

controller, you'll get exactly the same effect. Hard-wired flipper

solenoids would fire every time you press the buttons, whether or not

a game was in progress.

What about latency? When DOF was new, and people started switching

over to the DOF approach, there was some worry about the extra

software steps adding a noticeable lag time between pressing the

flipper buttons and hearing the feedback effects. Fortunately, it

turns out that DOF is fast enough that this isn't a problem. You

could measure the added latency using lab equipment, but it's not

enough to be perceptible to a human. The human nervous system has

a latency perception limit of about 30 milliseconds, and DOF in

a properly working system is comfortably faster than that.

The old-fashioned way: hard-wire the buttons to the solenoids

If you're using DOF, you should ignore this section, because there's

no reason to even consider hard-wiring the flipper buttons to the

flipper solenoids. However, if you're not using DOF, you can get some

very basic feedback effects by wiring your flipper buttons to your

flipper contactors or solenoids, so that pressing the buttons directly

activates the solenoids.

At first glance, it seems like it would be dead simple to wire the

buttons to the solenoids. The complication is that you also need to

wire the buttons to your key encoder, so that pressing the buttons

sends key presses to the PC, to operate the simulated flippers in

Visual Pinball and other pinball software. That dual wiring makes

things more complex because of the different voltages used in the key

encoder and the contactor or solenoid. The higher voltage needed for

the contactors or solenoids would damage or destroy the key encoder if

you wired both of them together directly. Instead, we have to isolate

the two voltages, so that the solenoid voltage doesn't damage the key

encoder.

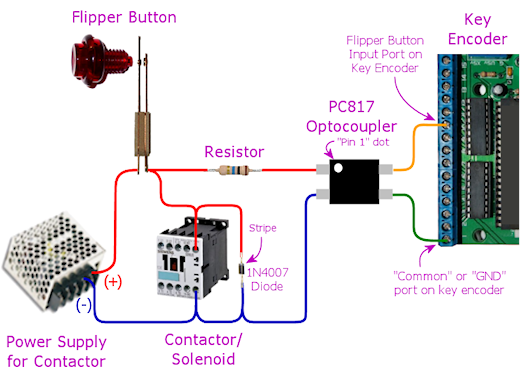

To isolate the voltages, we can use something called an "optocoupler".

That's a sort of solid-state relay that lets the voltage in one

circuit control a separate circuit with a different voltage, while

keeping the two voltages separated and isolated from one another.

Which is exactly what we need in this case.

If you've tinkered with electronics before, you might be more familiar

with regular mechanical relays, and you might be tempted to go with a

mechanical relay to keep things simpler. That would work, but I don't

recommend it, because mechanical relays are fairly slow. Slow enough

to cause an annoying amount of lag time in the software every time you

press the buttons. Mechanical relays also tend to wear out with heavy

use. Optocouplers are better because they're very fast and last a lot

longer.

Here's the basic circuit design that should work for any of the common

key encoders.

If you trace through the circuit, you'll see that the flipper button

is wired so that it activates both the contactor and the optocoupler

when pressed. Activating the contactor makes it fire, so you'll get

the flipper feedback effect whenever you press the button. Activating

the optocoupler completes the circuit on the key encoder side, so

pressing the button will also send the key press for the flipper

button. So whenever you press the button, you'll simultaneously hear

the flipper feedback effect and send the key press to the PC. The

optocoupler is the key to making both devices work together, because

it uses the higher voltage on the solenoid side to control the key

encoder side, but it does so without allowing the higher voltage to

reach the key encoder side.

The diode is needed to protect the rest of the circuit from the

voltage surge effect from the contactor or solenoid. A diode like

this is needed for every device with a coil or motor. See

Coil Diodes for more details.

Parts selection:

The PC817 optocoupler shown is only an example. Just about any

standard optocoupler should work, if there's another type you prefer

or that you can find cheaper.

The resistor has to be selected according to the contactor's power

supply voltage and the type of optocoupler you're using. Here are

the appropriate resistor sizes for the PC817 and common power supply

voltages for the contactor:

| Voltage | Resistor |

|---|---|

| 5V | 180 ohms, 1/8 Watt or higher |

| 12V | 560 ohms, 1/4 watt or higher |

| 24V | 1200 ohms (1.2K), 1/2 watt or higher |

| 48V | 2400 ohms (2.4K), 1 watt or higher |

If you're using a different optocoupler chip, the required resistor

values might vary slightly from the table above, so you should

calculate it using an LED resistor calculator. See

LED Resistors for help with this - that chapter includes an

interactive calculator that will figure the right resistance value

for you. You'll have to look up the following numbers in the data

sheet for your optocoupler, which you can then plug into the calculator

in the LED Resistors chapter:

- IF, the Forward Current for the optocoupler LED

- VF, the Forward Voltage (also known as Voltage Drop) for the optocoupler LED

Plug those two values into the calculator in the LED Resistors

chapter, along with the power supply voltage for your contactor, and

the calculator will tell you the size of resistor to use.