83. Ribbon Cables

A ribbon cable is a flat, insulated cable with some number of

conductors side by side, running parallel down the length of the

cable. Ribbon cables are ideal when you want to connect two (or more)

like connectors together. The flat geometry of the cable makes for

good signal propagation in high-speed data connections, which

is part of why these cables have long been used in the innards

of PC wiring.

You can buy pre-assembled ribbon cables in certain lengths and widths

(that is, the number of pins/conductors). However, it's hard to find

them in anything other than a few common widths.

Fortunately, it's easy to build your own ribbon cables. You can get

the bare cable in almost any length and width, and you can get the

connectors in almost any pin count. Building your own cables is also

cheaper than buying pre-assembled cables.

To build a ribbon cable, you need two types of parts:

- The ribbon cable itself

- IDC plugs, one for each end of the cable

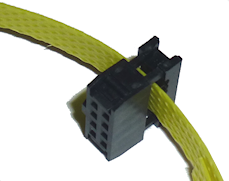

"IDC" stands for Insulation-Displacement Connector. This is the type

of connector normally used to build a ribbon cable. It attaches to

the cable via little teeth that pierce the insulation and grab the

wires, so all you have to install one of these connectors is

position and squeeze it, which clamps it onto the cable.

Buying ribbon cable wire

The wire making up a ribbon cable is a generic part that you can buy

anywhere. Mouser sells it by the foot, and you can also buy it on eBay,

Amazon, and at Fry's Electronic.

Here's a Mouser search that will turn up some suitable options:

(That's a search for IDC ribbon cables, no connectors, 1.27mm pitch.)

Selecting wire: Ribbon cable is usually sold by unit length (foot or meter).

Your vendor will probably have a giant spool and will cut the

length you ask for. When figuring the required length, measure the

distance between boards that the cable will have to cover, and add in

some length for bends and to leave some slack. I usually double the

apparent distance to make sure I have enough.

Apart from length, there are two main parameters when selecting cable:

the number of conductors, and the wire "pitch" (the distance from one

conductor to the next across the cable).

Pitch: For all of the expansion board connectors, you need

1.27mm pitch wire.

In general, ribbon cables have half the pitch of the pin

headers they connect to. The pin headers on the Pinscape expansion

boards used with ribbon cable connectors are all the standard 0.1" pin

pitch type, which equals 2.54mm. The matching ribbon cable pitch is

half of 2.54mm, or 1.27mm.

Number of conductors: The number of conductors for a given

connection has to match the number of pins on the header it connects

to. For example, the plunger connector on the main expansion board

(JP2) is an 8-pin (2x4) header, so it requires an 8-conductor ribbon

cable.

Splitting cables to make different widths: You can buy ribbon

cables in a variety of widths (Mouser currently carries it in even numbers

from 4 to 20 conductors), so you should be able to find it in each exact width

you need.

It's not strictly necessary to buy the exact width, though, thanks to a little

trick. You can easily tear a ribbon cable along the seam between any

two wires to split it into two cables. For example, if you buy a

16-conductor cable, you can split it along the seam between the 8th

and 9th wires to turn it into two 8-conductor cables. Or you can

split a 24-wire cable in a 16-wire plus an 8-wire cable. The reason I

mention this is that it's often cheaper to buy a single wider cable -

a 20- or 24-conductor cable, perhaps - and split it up into the narrow

widths you need.

Buying ribbon cable connectors

The specific connectors needed for the Pinscape boards are listed in

the parts list.

0.1" ribbon cable connectors are standardized, so you can mix and

match parts from different vendors for these. The Pinscape parts list

uses parts from the series listed below (use the series name as a

search key on Mouser to find the matching parts). These series

include similar parts for different numbers of pins/conductors, in

case you need to build cables for other pin header sizes.

- Kobiconn 164-9000 series, available in various sizes from 10 to 50 pins

- Wurth Elektronik WR-BHD series, available in various sizes from 6 to 64 pins

Assembling a ribbon cable

Step 1: Prepare the connector.

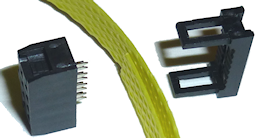

IDC plugs consist of two pieces that lock together around the cable,

with the cable sandwiched between them. New connectors usually come

with the two pieces loosely assembled but not locked, with a strip of

cardboard or plastic to keep them separated until you're ready to

assemble them.

To prepare them for installation, you might be able to slip them off

the end of the separator strip, or you might need to take the two

pieces completely apart to get them free. To separate them, just pull

them apart gently.

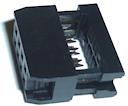

Be careful of the jagged metal teeth on the inside surface of the

lower piece. They're razor-sharp by design, so that they can easily

pierce the ribbon cable insulation when you install the connector.

Once it's free, loosely reassemble the connector if you had to

take it apart. Don't lock the two pieces together yet.

Maintain as big a gap as possible between the two pieces. The cable

has to feed into this gap.

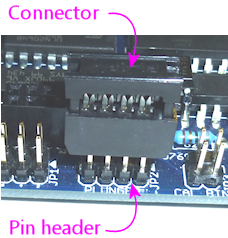

Step 2: Position the connector. Fit the connector

loosely onto the pin header where you'll ultimately plug this

guy in.

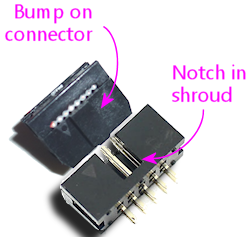

If you're using a shrouded header on the board, make sure that the

connector is oriented to match. Pay particular attention to the

little bump on one side of the connector - it should match up with

the slot on one side of the shrouded header. The bump and slot

are the "key" that makes sure you can't plug the connector in

backwards, so make sure they line up now.

Step 3: Cut the ribbon cable to the desired width and length.

If you're using the "zip" method to split a wide ribbon cable into

narrower cables, do so now to create a cable with the same number of

conductors as there are pins on the connector you're attaching.

Cut the ribbon cable to the desired length. Most ribbon cables

can be easily cut with scissors.

Step 4: Mark pin 1 on the cable. Use an oil-based

red Sharpie to mark one edge of the cable as the "pin 1" side.

You should use an oil-based marker because regular water-based

inks won't stick to the plastic insulation.

The cable is symmetrical, so it doesn't matter which side you

choose, but you should mark the cable down its whole length.

This will help you orient the connectors properly by providing

a visual marker to tell you were pin 1 is on the cable.

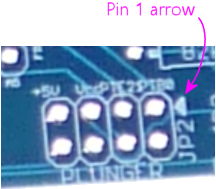

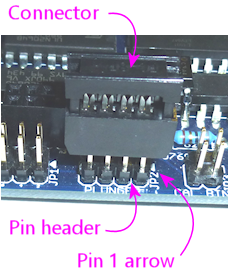

Step 5: Align the cable with the connector. Find the

pin 1 mark on the circuit board next to the header where this

cable plugs in. On the Pinscape boards, pin 1 is marked with

a little triangular arrow at one corner:

Position the cable so that the red stripe you marked on the

cable is on the same side as the pin 1 arrow.

You'll usually want the connector to be attached near one end of the

cable, so position the cable accordingly.

Step 6: Insert the cable. Keeping the connector and cable

oriented as they are, insert the end of the cable into the gap in the

connector. There cable should extend at least a little bit, perhaps

an eight of an inch, out of the other end of the connector. The cable

should fit precisely across the width of the opening.

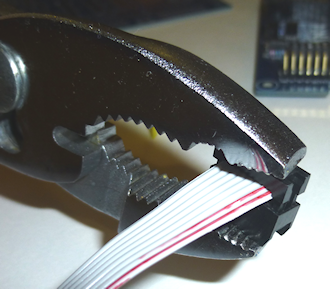

Step 7: Lock the connector. Take the connector off of the pin

header, take care to keep the cable and connector pieces positioned as

they were. Use an IDC crimp tool or a pair of pliers to squeeze the

two halves of the connector together. Apply flat, even pressure

across the whole width of the connector - it's important to press it

straight down so that the teeth align properly with the individual

conductors in the cable as they pierce the insulation.

Continue applying pressure until the two halves snap into place

and lock together.

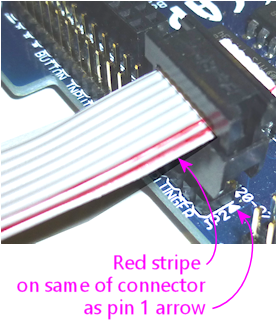

Step 8: Repeat for the other end. Repeat the whole procedure on

the other end. Be sure to align the cable properly so that the side

you marked with the red stripe for "pin 1" aligns with the circuit

board marking for pin 1 on the other end of the cable.

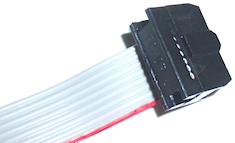

Multiple connectors on one cable

One more thing to note about ribbon cables is that the IDC plugs

aren't limited to the ends of the cable. They can also be attached at

any desired intervals along the cable. This lets you create a single

cable that connects three or more boards.

I use this feature on my own pin cab to connect two flasher panels

with a single 16-pin ribbon cable:

- An IDC plug at one end of the cable plugs into the output controller

- A connector at the other end of the cable plugs into the flashers on top of the backbox

- A connector midway along the cable plugs into the flasher panel at the back of the main cabinet