106. Plunger Setup (VL6180X Distance Sensor)

I should start by saying that I don't consider this to be a very good

option. I'm including it because it's easy to set up and fairly

cheap, so it might be appealing to some people on those grounds. It

also has the virtue of being a non-contact sensor, so it won't suffer

any wear and tear from use. But its accuracy and speed are too low

for me to recommend it. It's only accurate to about 1 centimeter,

which translates to chunky animation of the on-screen plunger (the

best available Pinscape plunger sensors are accurate to better than

1/100 of a centimeter). It's also comparatively slow, which makes it

less responsive than other options. With those warnings in mind...

The VL6180X is a distance measuring sensor that works by sending out

pulses of IR light aimed at a target, detecting the reflected pulses

with a photosensor, and measuring the round-trip travel time of each

pulse. It uses the travel time to determine the distance, using the

known speed of light in air.

To use this for a virtual pinball plunger sensor, the basic idea is

install the sensor at a fixed position just beyond the end of the

plunger, with the sensor pointing at the tip of the plunger. As you

pull back the plunger, the distance between the sensor and the plunger

increases. The sensor's distance measurement tells us the plunger's

current position.

VL6180X vs. VL53L0X

The VL53L0X is a newer chip from the same manufacturer with similar

distance measurement features. It's not an outright replacement for

the VL6180X, as it's not software-compatible and doesn't have exactly

the same features. Its main advantage over the older chip is that it

has a much higher maximum ranging distance, up to about 200cm vs only

10cm for the VL6180X. However, there's a tradeoff: it's considerably

slower than the VL6180X. The VL6180X completes a distance measurement

in about 13ms, whereas the VL53L0X requires at least 19ms, and is

happiest at about 35ms. In my testing, the newer chip doesn't have

any accuracy improvements over the old one.

Given the tradeoffs, I don't see any reason to use the VL53L0X over

the VL6180X for plunger sensing. The longer range of the newer chip

doesn't make any difference for us since we don't even need the full

range of the older chip, and the reduced speed is a negative. If the

newer chip's accuracy were noticeably better, that would make it more

of a contest, but both chips seem to have about the same (poor) accuracy.

Electronics

You can buy pre-assembled VL6180X circuit boards from several robotics

hobby companies. This is lucky for us, because the bare chips are

rather challenging to work with. The pre-fab boards make them easy to

use.

Here are three options:

All of these options are pretty much equivalent. They all provide

easy-to-solder terminals for all connections, and they all have the

necessary on-board voltage regulators and level shifters to interface

the VL6180X with the KL25Z. Any of these boards can be used directly

with the KL25Z hardware and Pinscape software; the only thing you

have to do is run a few wires between the KL25Z and the sensor board.

The instructions below are designed around the Pololu board. I chose

that one as the reference point because it's the cheapest and smallest

option. You can substitute one of the others if you prefer, but be

aware that you'll have to adapt the instructions below for any

differences in the board you choose. The other boards are all very

similar, so this shouldn't be difficult, but keep it mind as you build

the project.

Wiring the board

The breakout boards all come fully assembled, except for external wire

connections. The only thing we have to do is attach the wires between

the board and the Pinscape controller.

Your board might come with a set of pin headers that you can

optionally solder to the pads on the board. You can use these if you'd

like, but I'd actually recommend soldering wires directly to the pin

pads instead of using the pin headers. Using the pins creates a bit

of extra work, since you'll have to build an extra connector to plug

into the pins. I'd skip the pins and solder wires directly to the

board terminals, since you really shouldn't ever need to disconnect

the wires from the sensor board. We will use pluggable connectors at the

other end, where we plug into the Pinscape board, so you'll still

be able to easily unplug the whole assembly if you ever need to remove

it from the cabinet.

I recommend 24 AWG stranded wire for the connections, but the exact

gauge isn't important, as these wires carry extremely low power.

You'll need five wires, about three feet long each. Before cutting

the wires, check the length you'll need by measuring the distance the

wire will have to traverse to reach from your plunger housing to the

Pinscape unit (the KL25Z or main expansion board). Take into account

any extra length you need to route it around your PC motherboard or

other obstructions.

Strip about 1/4" of insulation from each end of each wire.

Solder one wire to each of the following terminals on the board:

- VIN (Adafruit and Pololu) or VCC (Sparkfun) (not VDD or 2.8V)

- GND

- SDA

- SCL

- GPIO0/CE (Pololu), SHDN (Adafruit), or IO0 (Sparkfun)

Note that your board will have some other terminals besides those listed

above. You can simply leave other terminals unwired.

Be careful about the "VIN" voltage input terminal! This one can

be a little confusing because some of the boards have two "V"

terminals. One is for the input voltage: this is the

one we want to connect. The other is for the output of the on-board

2.8V voltage regulator. We don't want to connect anything to

the 2.8V output. On the Adafruit board, the 2.8V output is plainly

labeled as "2v8", while it's more obscurely labeled on the Pololu

board as "VDD". In either case, just leave this terminal unconnected.

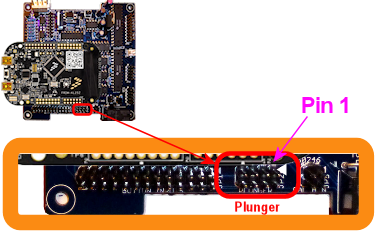

Expansion board wiring

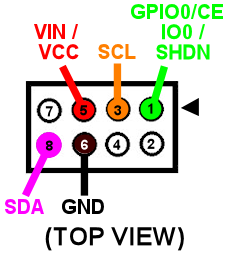

For the expansion board connector, build a 4x2 crimp pin housing

(housing, pins).

First crimp a pin to the end of each wire (see Crimp Pins).

Insert the pins in the housing, following the diagram below for the pin placement.

It would be a good idea to put a mark of some kind on the housing in

the corner next to pin 1 - the pin marked with the arrow on the

diagram above. That will make it easier to remember which side

aligns with the "pin 1" arrow marker on the circuit board when

you plug in the connector.

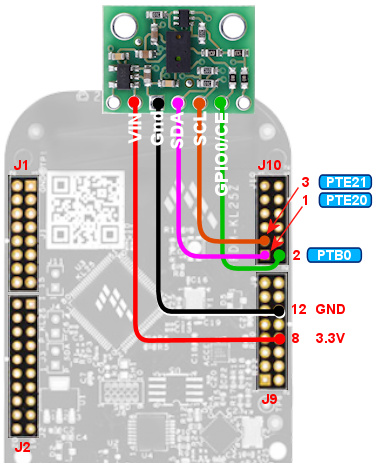

Standalone KL25Z wiring

For the standalone KL25Z, I recommend using the plunger

sensor breakout board. Then you can just plug it into the breakout board.

- Build the expansion board connect as described above

- Build the ribbon cable connector exactly as described above, as though you were using the expansion boards

- Follow the instructions in Plunger Sensor Breakout Board to build the breakout board

- Connect the following wires between the breakout board and the KL25Z:

- Breakout board 3.3V to KL25Z P3V3 (pin 8 on J9)

- Breakout board GND to KL25Z GND (pin 12 or 14 on J9)

- Breakout board B0 to KL25Z PTB0 (pin 2 on JP10)

- Breakout board E20 to KL25Z PTE20 (pin 1 on JP10)

- Breakout board D0 to KL25Z PTE21 (pin 3 on JP10) (Yes, the label on the breakout board is different in this case)

If you prefer to use your own ad hoc wiring, see "Plug it in" below for

the list of KL25Z GPIO connections.

Physical installation

I haven't come up with a reference design for the housing for this

sensor, so you'll have to come up with something on your own. The

basic idea is to mount the sensor at a fixed position in your

cabinet so that it faces the tip of the plunger head-on. The point

is to measure the distance between the sensor and the plunger.

There have been several commercial virtual pinball plunger kits

available over the years that were also based on IR proximity sensors,

so we can look to them as examples for how we might set this up. All

of those used a plastic tube surrounding the plunger, with the sensor

installed at the far end of the tube, facing the plunger tip. The

plastic tube serves dual purposes: it provides a place to mount the

sensor, and it shields the whole area from stray light that could

interfere with the sensor's readings. The VL6180X actually doesn't

actually need such shielding as much as the older sensors used in the

commercial kits do, since it has a "laser ping" design that's pretty

good at ignoring ambient light, but even so, it wouldn't hurt.

Choosing a material for the tube: This isn't as simple as it might

seem! Intuitively, it seems like any kind of opaque material would be

good. But the sensor uses infrared light (technically, 850 nm), and

many materials that look opaque to our eyes are actually transparent

to IR. The common 3D printer plastics PLA and ABS are both partially

transparent to IR, so it would somewhat defeat the purpose to use them

for a light shield. Black PETG is supposed to be nearly opaque to IR,

so it might be a better choice. It might also be a good idea to make

the inside surface texture of the tube or cover somewhat rough, to

minimize reflections. A smooth surface that readily reflects the

signal might be worse than no cover at all.

Choosing the sensor mounting position: Make sure that the sensor is

far enough away from the end of the plunger's range of motion that the

plunger won't ever hit the sensor. Remember that the plunger springs

forward about half an inch from its resting position, because the

barrel spring on the front can compress a bit. Leave a gap of at

least 1 centimeter (about half an inch) if possible.

When you mount the board, be sure to mount it with the component

side facing the plunger.

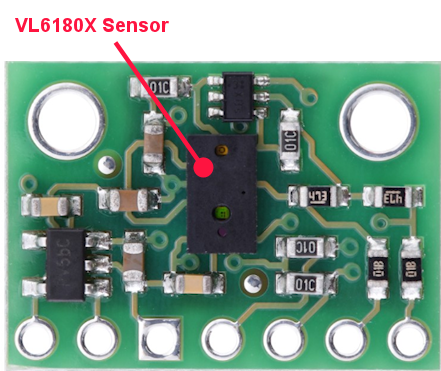

Here's what the Pololu board looks like. The sensor is the little

black box in the middle with two small holes (one hole is the laser

emitter, the other is the photosensor). The sensor chip looks the

same on all of the boards, but the layout of the terminals and

the other parts varies slightly.

Plug it in

Expansion boards:

Once you've built the connector as shown above, simply plug it into the

plunger connector on the main expansion board. Make sure the plug orientation

is correct by match pin 1 in the housing (see the diagram)

with the pin 1 triangle printed on the expansion board.

Standalone KL25Z:

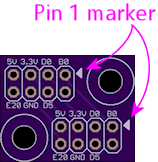

If you're using the plunger sensor breakout board (recommended), build the

expansion board connector as described above, and just plug it in to the

pin header on the breakout board. Be sure pin 1 on the plug (see the diagram)

to pin 1 on the board, which is marked with a little white triangle

printed next to the header.

If you prefer to use your own ad hoc wiring, connect the wires between

the board and the KL25Z as shown below.

| Sensor Board Pin | KL25Z Pin |

|---|---|

| 3.3V | P3V3 (JP9-8) |

| GND | GND (JP9-10) |

| SDA | PTE20 (JP10-1) |

| SCL | PTE21 (JP10-3) |

| GPIO0/CE | PTB0 (JP10-2) |

Note that the last pin, GPIO0/CE, has different names on some of the

boards: it might be labeled IO0 or SHDN. It's the same pin in any

case; the different board makers just chose to give it different

labels.

The illustration below shows the Pololu board. Be sure to adjust the

pin ordering if you're using a different board. Just match the labels

shown on the diagram to the labels printed on your board.

Note that the three GPIO ports listed above are only suggestions. If

you're already using the same ports for other functions, you can

assign the sensor inputs to other ports using the Config Tool. Any

free GPIO ports can be used with this sensor (it doesn't have any

special requirements for particular ports). The power and ground

wires aren't configurable, though, so connect those as shown.

Software setup

Once you have the sensor physically installed and plugged in, run the

Pinscape Config Tool on your PC. Go to the Settings page. (If you

have multiple Pinscape units installed, choose the Settings page for

the unit that's plugged into your new plunger sensor.)

Go to the Plunger Sensor section. Select VL6180X in the "sensor type"

popup.

(If the VL6180X option isn't available in the plunger sensor list,

you probably have an older version of the Config Tool. Updating to

the latest version should add the option.)

If you're using the expansion boards, the pin settings will be

set up automatically.

If you're using the standalone KL25Z, set the pin assignments for the

three pins (SDA, SCL, and GPIO0/CE) to match the pins you connected

on the KL25Z. The SDA and SCL pins should match the pins you

wired to the like-named terminals on the sensor board. The last one,

GPIO0/CE, goes by different names on the different boards: on the

sensor board, it will be labeled as GPIO0/CE, IO0, or SHDN, depending

on which type of board you have.

Save the new settings by clicking "Program KL25Z" at the bottom of the

window.

You should now test and calibrate the plunger. Return to the home

screen in the Config Tool and click the Plunger icon for the unit

with the sensor attached. This will let you look at the raw sensor

input. Move the plunger and make sure it seems to be tracking

properly.

If the sensor is working properly, click the Calibrate button in

the plunger viewer window to begin the calibration process, and

follow the on-screen instructions.

If the sensor doesn't seem to be working, go back to the Settings screen and

double-check the sensor pin assignments. Make sure that none of the pins

are marked with warning icons ( ).

Check each wire and make sure that it goes to the proper pin on

each end (KL25Z and sensor board). Check that each GPIO port

assignment on the settings page matches up with the physical

pin on the KL25Z and connects to the corresponding terminal

on the sensor board.

).

Check each wire and make sure that it goes to the proper pin on

each end (KL25Z and sensor board). Check that each GPIO port

assignment on the settings page matches up with the physical

pin on the KL25Z and connects to the corresponding terminal

on the sensor board.

).

Check each wire and make sure that it goes to the proper pin on

each end (KL25Z and sensor board). Check that each GPIO port

assignment on the settings page matches up with the physical

pin on the KL25Z and connects to the corresponding terminal

on the sensor board.

).

Check each wire and make sure that it goes to the proper pin on

each end (KL25Z and sensor board). Check that each GPIO port

assignment on the settings page matches up with the physical

pin on the KL25Z and connects to the corresponding terminal

on the sensor board.

Jitter filtering

The VL6180X generates distance readings in millimeters, but it's

really only accurate to about a centimeter, so the millimeter numbers

it comes up with are pretty much just wild guesses. As a result, the

readings fluctuate quite a bit from one reading to the next, even when

the target is standing still. With a stationary object, you'll see

the readings jump around constantly within about 5mm of the true

distance, plus or minus. This is annoying and unrealistic during

virtual pinball play, because it makes the on-screen plunger dance

around nervously when the real plunger is standing still.

The Pinscape firmware offers a "jitter filter" to deal with this. The

jitter filter lets you set a range for ignoring random fluctuations. As long

as the random noise from the sensor stays within the range, the device

ignores the fluctuations and reports a stable, stationary plunger.

The on-screen plunger only moves when the sensor readings move outside

of the noise window.

To enable the jitter filter, run the Pinscape Config Tool and go to

the Plunger Viewer window. There's a setting in this window for the

jitter filter. To adjust it, start with the filter at zero, and

gradually increase it until the green bar showing the filtered reading

stops jumping around. Use the smallest value that gives you

acceptable results, because larger values will reduce the usable

precision during play.

Backwards operation

If the on-screen plunger moves backwards from the real plunger, you

can fix it in the software without reinstalling the sensor. Open the

Pinscape Config Tool. In the row for the controller, click the

Plunger icon. Check the box for "Reverse orientation". (If it's

already checked, un-check it.) This tells the software to reverse the

readings from the sensor, so that it acts like it was installed in the

opposite orientation.