This section provides details on all of Pinscape Pico's JSON configuration file elements.

For an introduction to the JSON syntax and the overall file layout, refer to Config File Format.

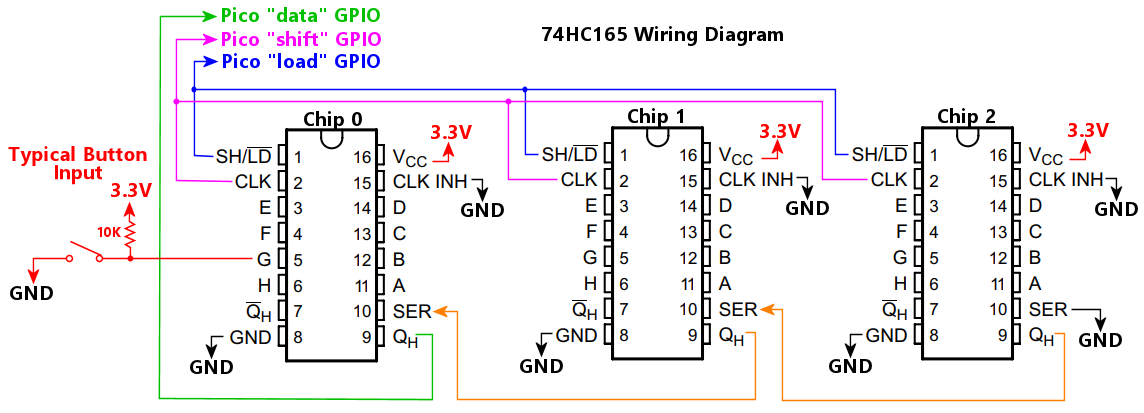

Configures one or more daisy chains of 74HC165 input shift register chips. These ports can be used to add digital input ports to the Pico, which Pinscape can use as button inputs. These chips are inexpensive and easy to work with in circuit board designs.

These chips provide an extremely low-latency input interface that's expandable to a large number of inputs. The Pinscape software scans these ports using the Pico's dedicated programmable I/O hardware, which allows bit clocking at megahertz speeds, for read latencies of a few microseconds. These chips are essentially as fast as the Pico's native GPIO ports.

The 74HC165 ports don't have any internal pull-up or pull-down resistors, so if you're using the chip to read button switches, you have to provide your own pull-up or pull-down resistor on each port so that it has a definite input voltage when the button switch is open. Leaving a port free-floating without any pull-up or pull-down reference resistor will make the chip read random input levels on the port. If you're using an expansion board designed for Pinscape, it probably has the resistors built in; if you're designing your own boards, you should include suitable resistors in the design. The standard setup is to connect each 74HC165 port to a pull-up resistor, around 10K, that connects on the other end to 3.3V. Then connect one terminal of each switch to a 74HC165 port, and connect the other switch terminal to DC ground (GND or 0V). The 74HC165 port will read as LOW when you press the button, HIGH the rest of the time.

These chips are designed to be chained together in a daisy chain, one chip connecting to the next, with only one chip connected directly to the Pico. That allows multiple chips to be connected while only taking up the GPIOs needed to connect one chip. Pinscape allows you to set up multiple daisy chains, each chain having its own set of GPIO connections, but there's little reason to do this in most cases given that you can just add more chips as needed to a single chain. If you do set up multiple chains, configure the "74hc165" property as an array of objects, with one object per daisy chain.

The "74hc165" property in the JSON file must be enclosed in double-quotes, because it starts with a digit rather than a letter.

The Pico GPIO port number connected to the serial output pin on the chip, labeled QH on the TI data sheet, or Q7 on the NXP data sheet.

Note that the chip also has an inverted output, labeled

Connect this GPIO port to the to the QH or Q7 pin on the first chip on the daisy chain only. Unlike the "shift" and "load" GPIO ports, don't connect this GPIO to all of the chips on the chain. Connect it to the first chip only.

The QH (or Q7) ports are what form the daisy chain. Connect the second chip's QH serial input port to the first chip's Serial Out pin, which is labeled SER on the TI data sheets, or DS on the NXP data sheet. Connect the third chip's QH/Q7 to the second chip's SER/DS pin, and so on down the chain. The last pin's SER/DS pin should be connected to ground.

The Pico GPIO number port connected to the "load" pin on the chip. This is labeled SH/LD (Shift/Load) on TI data sheets, or /PL (Parallel Load) on NXP data sheets. Connect this port to the SH/LD pins on all of the chips in the chain.

Sets the polarity of the "load" pin that selects LOAD mode. (The "load" pin is labeled SH/LD on TI data sheets, or /PL on NXP data sheets.)

This type of chip has two modes, selected by the "load" pin: SHIFT mode, where the chip transfers the contents of the shift register to the host microcontroller, and LOAD mode, where the chip loads the shift register from the 8 input pins. On the original 74HC165 chips, the mode selection is controlled by the SH/LD pin, and taking the pin LOW puts the chip in LOAD mode.

The reason this property is provided is that there are some other types of serial-input chips that are almost identical to the 74HC165, except that they invert the logic of their version of the SH/LD pin, so that setting the pin to "high" enables load mode. This software option is designed to give the Pinscape 74HC165 code enough flexibility to also work with this almost-identical chips, so that we don't need to create a whole separate chip type in the software to deal with this one small difference. If you're using one of those almost-but-not-quite-74HC165 chips, set loadPolarity according to the sense of your chip's version of the load/shift pin. If LOAD mode is activated by taking the pin HIGH, set this property to true; otherwise set it to false.

The number of chips making up the daisy chain. This is required so that the software knows how many ports to read on each input cycle.

The Pico GPIO port number connected to the "shift clock" pin on the chip, labeled CLK (Serial Clock) on the TI data sheet, or CP (Clock Input) on the NXP data sheet. Connect this port to the CLK pins on all of the chips in the chain.

Sets the clock rate, in Hz, for the shift clock signal sent to the daisy chain on the CLK pin (labeled CP on the NXP data sheet). This determines the data bit rate used to transfer port ON/OFF data from the chips to the Pico. The default is 6000000 (6 MHz), which is a conservative default based on the limits specified in the TI SN74HC165 data sheet. Higher frequencies allow faster polling of the input ports, but the chips will only operate correctly up to a limit, and higher frequencies are also more vulnerable to electronic noise in the wiring. That makes the usable limit vary by setup, so Pinscape makes it an adjustable parameter. The optimal setting is the highest value that works reliably with your setup. The default is conservative enough that it should work for most setups, but should also be fast enough for most needs (at 6 MHz, it takes 12us to transfer the data for 64 ports).

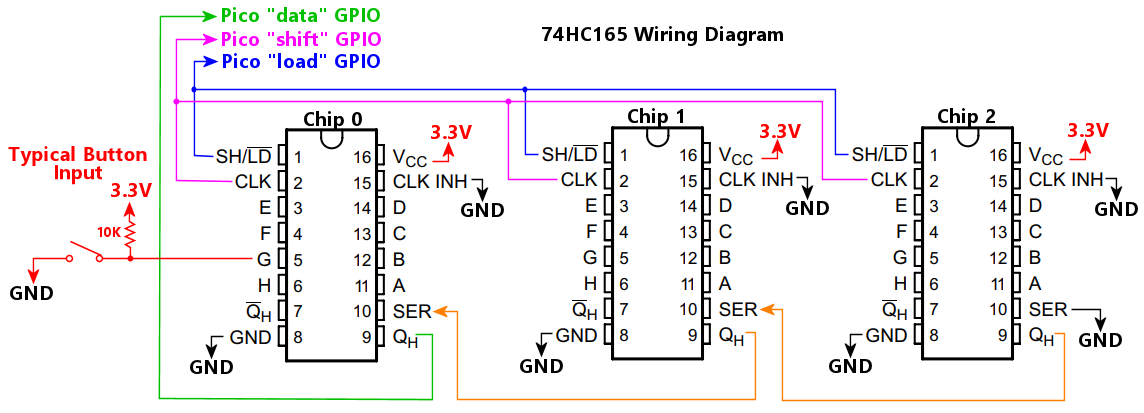

Configures one or more daisy chains of 74HC595 output shift register chips. These ports can be used to add digital (on/off) or PWM output ports to the Pico, which Pinscape can use as feedback device outputs. These chips are widely available, inexpensive, and easy to work with in circuit board designs, so they're an attractive option if you're designing custom hardware.

These chips are designed to be chained together in a daisy chain, one chip connecting to the next, with only one chip connected directly to the Pico. That allows multiple chips to be connected while only taking up the GPIOs needed to connect one chip. Pinscape allows you to set up multiple daisy chains, each chain having its own set of GPIO connections, but there's little reason to do this in most cases given that you can just add more chips as needed to a single chain. If you do set up multiple chains, configure the "74hc595" property as an array of objects, with one object per daisy chain.

At the hardware level, the 74HC595 is a "digital" output port chip: all of the ports are simple ON/OFF switches. However, Pinscape Pico can optionally provide PWM brightness control through these chips, by rapidly switching the ports on and off to modulate their duty cycle proportionally to the desired brightness level, across the 256-step brightness scale that DOF uses. These aren't ideal chips for PWM ports, because the rapid switching requires a very high data rate to the chip, in the megahertz range. This might not work reliably (or might even not work at all) with some circuit boards, since such high signal rates are vulnerable to electrical noise and interference, so they require careful wiring to work reliably. The best bet is to integrate the Pico and the 74HC595 chips into a single circuit board, placing all parts close together with short circuit traces. Setups with external cabling between the chips and the Pico might be less reliable. In addition, even with megahertz data rates, these chips can still only achieve relatively modest PWM refresh rates, in the hundreds of Hertz, depending on how many chips are on the daisy chain: 1-2 chips will run at about 1000 Hz, and 7-8 chips will reduce the rate to around 240 Hz. (It might seem strange that the PWM rates are so sluggish when we were just talking about megahertz data rates, but there's a good reason. The PWM rate is a small fraction of the data clock rate, because the Pico has to switch the ports on and off many times during each PWM cycle. This requires sending many data bits to the chip on each PWM cycle. The overall PWM cycle time reflects the time it takes to send all of these bits over the course of a cycle.) 200+ Hz is plenty fast to eliminate any trace of flicker with LEDs, but it might be too slow for inductive devices like motors and solenoids, since some of those are prone to audible buzzing or whining when run at such low PWM frequencies. If you do run into any noise problems driving motors or solenoids with these chips, you might have to move those devices to some other output chip that can achieve higher PWM rates, such as TLC59116, or a Pico GPIO port.

The "74hc595" property in the JSON file must be enclosed in double-quotes, because it starts with a digit rather than a letter.

Wiring notes:

The Pico GPIO port number connected to the DS (serial data) pin on the first chip on the daisy chain only.

Unlike the "shift", "latch", and "enable" GPIO ports, this GPIO is not connected to all of the chips on the daisy chain. Instead, this GPIO connects only to the first chip on the chain. The other chips on the chain still need data port inputs, but each chip gets its input from its nearest neighbor - that's what actually forms the daisy chain, as each chip passes its data output to the next chip's data input. The second chip's "serial in" DS port connects to the first chip's "serial out" port, labeled Q7S on the data sheet. The third chip's DS connects to the second chip's Q7S. And so on down the chain.

For the last chip on the daisy chain, you can leave the Q7S serial data out pin unconnected, or you can connect it to ground through a high-value resistor, perhaps 100K. Connecting it to ground in this fashion might help reduce its propensity to like an antenna, broadcasting radio-frequency noise.

The Pico GPIO port number connected to the OE (output enable) pin on the chips.

Alternatively, this can be an object, using the same syntax as outputs[].device. This allows you to connect the OE pin to a GPIO extender such as a PCA9555, saving a GPIO port on the Pico.

Connect the Pico port you select to the OE pins on all of the chips in the chain. Also connect the port to 3.3V through a pull-up resistor, typically 10K. The pull-up resistor ensures that the OE signal is pulled high, disabling all of the 74HC595 output ports, during the brief time after power-up when the Pico's GPIO pins are in their initial high-impedance state. Without the pull-up resistor, the OE signal would be left floating immediately after power-up, which might cause the 74HC595 ports to randomly activate, firing connected devices briefly.

The Pinscape software uses the OE signal to ensure glitch-free startup. 74HC595 chips power up with random values in the shift register, so it's important to disable all of the 74HC595 output ports immediately at power-up, until the Pico has a chance to set all of the ports to OFF. The Pinscape software initializes all of the ports to OFF very soon after a reset, but there's a brief time window after power-up before this initialization step occurs. If the 74HC595 ports are enabled during this brief time window, attached devices can be randomly triggered, due to the random initial ON/OFF values in the shift register. Pinscape holds the OE line high until it completes the initialization step, which ensures that the random values in the shift register aren't ever visible on the output pins, in turn preventing any random device activation. Connecting OE to both a Pico port and a pull-up resistor ensures that the OE line is held high from the very instant power is applied.

The OE connection is optional. You can simplify your hardware design by simply connecting the OE pin directly to GND (0V), which permanently enables the output ports. But doing this might result in startup glitches, because it will enable the 74HC595 output ports immediately after power-on, when the shift register contains random on/off values. Any shift register positions that are randomly ON will cause the associated ports to turn ON, firing the attached devices. As soon as the Pinscape software starts running, it will turn all of the ports off again, so the initial random device activation will only last for a fraction of a second, which is why we call it a "startup glitch". This might not be a problem at all for some setups, such as when all of the output devices are LEDs; a brief random LED flash at startup probably won't bother anyone. Glitches are more objectionable when noise-making devices like solenoids or motors are involved, since it can be alarming to have a bunch of solenoids all fire at the same time.

The Pico GPIO port number connected to the latch/transfer pin on the chips, which is labeled STCP on some data sheets, RCLK on others. Connect this to the STCP/RCLK pins on all of the chips in the chain. The GPIO port must be the next higher GPIO port after the 'shift' port; for example, if 'shift' is on GPIO 15, 'latch' must be on GPIO 16.

The number of chips in the daisy chain. This is required so that the software knows how many ports to update on each output cycle.

Sets the operating mode for the chain: true configures the chain in PWM mode, false (the default) configures it in digital mode. In digital mode, the outputs are simple on/off switches. When used as DOF ports, any non-zero DOF "brightness" setting switches the port ON, and a zero DOF level switches the port OFF. In PWM mode, the outputs have full DOF brightness control, with the same 0-255 range that DOF uses.

The Pico GPIO port number connected to the the shift clock pin on the chip, labeled SHCP in some data sheets and SRCLK in others. Connect this to the SHCP pins on all of the chips in the chain.

Sets the clock rate, in Hz, for the shift clock (SHCP/SRCLK) signal sent to the daisy chain. This determines the data bit rate used to transfer port ON/OFF data from the Pico to the chips. The default is 4000000 (4 MHz), which is a conservative default based on the limits specified in the TI SN74HC595 data sheet. Higher frequencies allow faster updates of the output ports, but the chips won't function properly if the frequency is too high for them to process, so the optimal frequency is the highest value that works reliably. That will vary from one setup to the next, since many factors affect the maximum usable speed, such as the specific type of 74HC595 chips you're using (there are several variants on the market) and the physical layout of your circuits boards and cabling. The default should be fine for most setups, but if you encounter any glitching on the outputs, you can try reducing the rate to see if that improves matters.

When operating the chip in digital mode (where the ports are purely ON/OFF switches with no brightness control), the clock speed doesn't need to be very fast; a setting as low as 100000 Hz should be fine. The speed is much more important when operating the chips in PWM mode, because it determine the PWM refresh cycle period, which must be at least 100 Hz to avoid visible flicker if you're using the chips to control lighting devices like LEDs. The default setting of 4000000 Hz yields a refresh rate around 240 Hz with an 8-chip daisy chain (and shorter daisy chains are proportionally faster), so it should be a good compromise between PWM refresh rate and signal integrity. If you find that outputs are flaky, you can try reducing the clock speed, but LED flicker might become noticeable if you go below about 1000000 Hz. You can also try increasing the clock rate if you want to take the PWM refresh rate higher, although I don't think there's much benefit to doing so. LED flicker should be fully gone at 200 Hz, so there's no need to go higher just for the sake of lighting devices. The main reason you might want to drive the PWM rate much higher than 200 Hz would be to address acoustic noise problems in inductive devices like solenoids and motors, and to do that, you generally have to raise the PWM rate to about 20 kHz, so that it's beyond the human hearing range. That's unfortunately not possible with these chips, because it would require a shift clock rate in the 300 MHz range, which is far beyond the documented limits of these chips even under the best conditions.

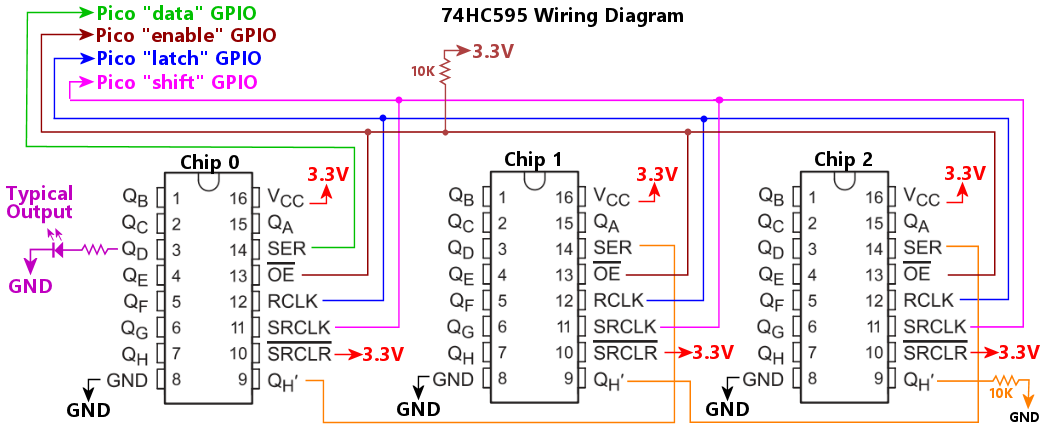

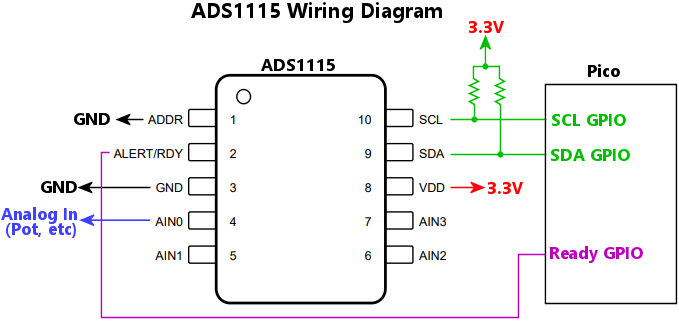

Configures one or more ADS1115 analog-to-digital converter (ADC) chips. If multiple ADS1115 chips are connected, use an array of this object type, one for each chip.

Why would you want to use an external ADC like ADS1115, when the Pico already has a built-in ADC of its own? Because the Pico's built-in ADC is mediocre at best. An external ADC might be preferable if you're using a potentiometer as your plunger position sensor, because the quality of the position readings from a potentiometer depends upon the quality of the ADC. The Pico's built-in ADC only has about 8 bits of digital resolution, so it can only distinguish a few hundred position increments - and even fewer after taking into account analog noise. That's not good enough for truly smooth animation in the pinball simulators. ADS1115 has 16-bit resolution, allowing for much finer increments of position readings, which can make for smoother animation and more consistent physics behavior in the simulators.

Wiring notes:

The 7-bit I2C address of the chip. The chip's address is configured by the wiring on its ADDR pin, which can select among four addresses (0x48, 0x49, 0x4A, 0x4B). Set this property according to the ADDR pin wiring.

The input channel number or numbers you're using on the chip. The ADS1115 has four input pins, AIN0 to AIN3, that can be connected to up to four separate analog inputs that you want to measure. This property lets you tell Pinscape how these map to "logical" channels, which are the channels that Pinscape actually reads. If you only need to measure one input voltage with the chip, you only need to configure one logical channel.

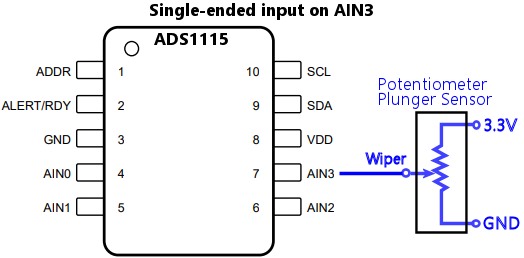

The simplest way to connect voltage inputs to the ADS1115 is as "single-ended" inputs, where each AINx pin measures a positive voltage relative to GND. This configuration is suitable for the most common virtual pin cab use case, which is measuring the voltage on a potentiometer, such as a plunger position sensor or a joystick. To use this configuration, simply connect the analog voltage source you wish to measure, such as the wiper pin from a potentiometer, to one of the AINx pins. List the AINx pin number in the channel property. For example, if the pot wiper is connected to AIN3, use channel: 3 to set up a logical channel reading from pin AIN3.

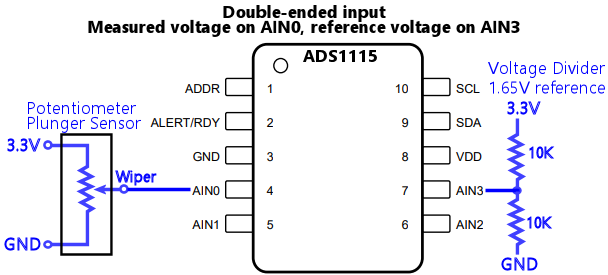

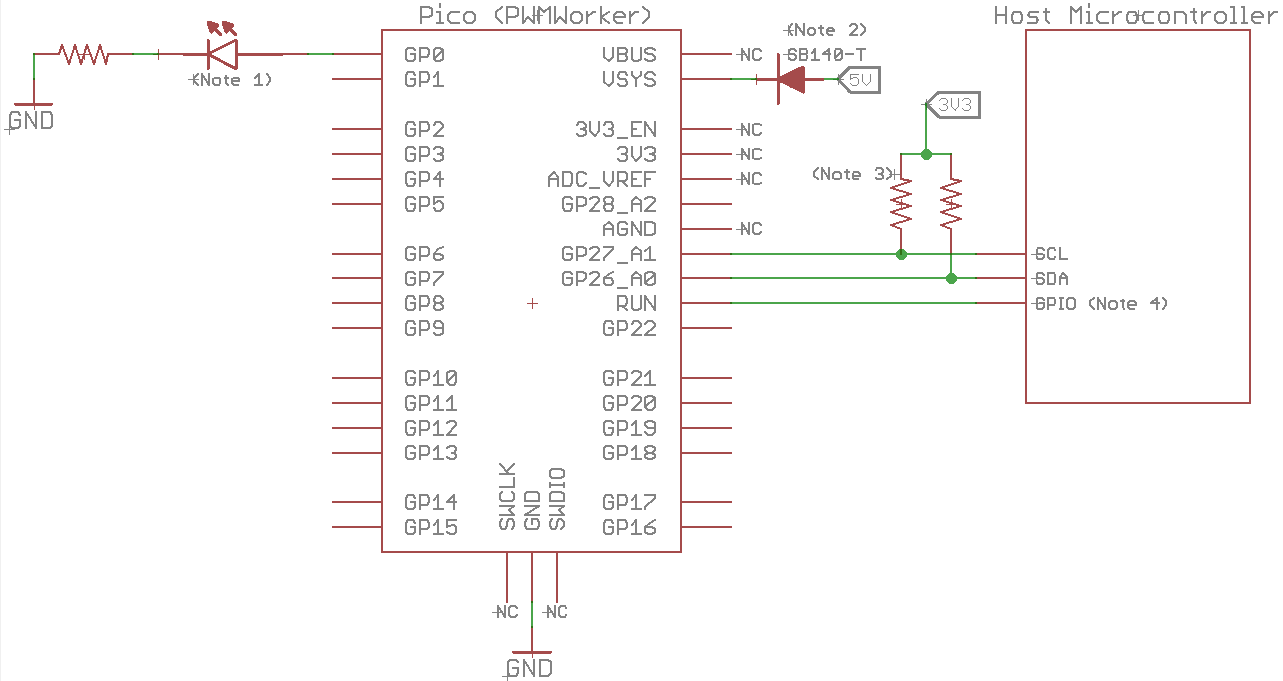

The ADS1115 also allows "double-ended" inputs, where you use two AINx pins to measure the voltage differential between two signals. This lets you use a positive voltage as the reference point, instead of GND. This is especially useful if you have a separate analog power supply with a more precise voltage regulator than the digital 3.3V supply, or if the voltage being measured only varies over a small portion of the 3.3V range. The reference Pinscape Pico expansion boards take advantage of the differential capability by providing a voltage divider to create a 1.65V voltage reference on AIN3, as shown in the diagram below; use channel: "AIN0/AIN3" for this wiring arrangement. The benefit of this setup is that you can use a smaller amplifier range setting in the ADS1115 input stage, since the potentiometer reading can only vary from -1.65V to +1.65V relative to the 1.65V reference on the divider. This effectively adds one bit of resolution to the digitized result.

The ADS1115 only allows double-ended inputs on certain channel pairings, as shown below.

| Value | Channel configuration |

|---|---|

| 0, "0", or "AIN0" | Single-ended, AIN0 (referenced to GND) |

| 1, "1", or "AIN1" | Single-ended, AIN1 (referenced to GND) |

| 2, "2", or "AIN2" | Single-ended, AIN2 (referenced to GND) |

| 3, "3", or "AIN3" | Single-ended, AIN3 (referenced to GND) |

| "0/1" or "AIN0/AIN1" | Double-ended, positive=AIN0, negative=AIN1 |

| "0/3" or "AIN0/AIN3" | Double-ended, positive=AIN0, negative=AIN3 |

| "1/3" or "AIN1/AIN3" | Double-ended, positive=AIN1, negative=AIN3 |

| "2/3" or "AIN2/AIN3" | Double-ended, positive=AIN2, negative=AIN3 |

You can set up multiple logical channels, by using an array for the channel property. And you can freely mix and match single-ended and double-ended inputs. For example, channel: ["0/1", 2] sets up two logical channels, one that reads a double-ended input on pins AIN0/AIN1, and a second that reads a single-ended input on AIN2.

The ADS1115 can physically only sample one channel at a time, so if you configure multiple channels, the chip has to cycle through the channels in a round-robin rotation. This slows down the sampling rate for each channel by a factor of N (the number of channels configured), because the chip has to complete an entire sampling period for each channel before moving on to the next. For time-critical devices like a plunger sensor, it's better to devote the whole ADS1115 chip to a single input so that the chip doesn't have to divide its time among other inputs. You can connect up to four ADS1115 chips to the Pico, so if you need multiple inputs and maximum speed per input, the best approach is to connect multiple ADS1115 chips.

The I2C bus number, 0 for I2C0 or 1 for I2C1, where the chip is connected.

The GPIO port connected to the chip's ALERT/RDY pin. You can omit this if the pin isn't connected to a Pico port. It's preferable to connect the pin to the Pico, because it allows more efficient use of the I2C bus by letting the Pico know when a new sample is ready without any unnecessary I2C polling.

The sampling rate, in samples per second. This determines the rate at which the chip produces samples for the Pico to read across the I2C connection; internally, the chip collects samples at a higher rate, and averages them over the I2C reporting period, so longer periods improve the sampling quality by averaging out noise in the signal. The chip only supports certain fixed rates: 8, 16, 32, 64, 128, 250, 474, and 860 samples per second. You can set sampleRate to any value, but the actual rate will be set to the closest of those allowed rates. The default is 860.

Sets the full-scale voltage range for the ADS1115 inputs. The ADS1115 has an internal amplifier that can be configured to scale the voltage input to different ranges. This is useful because it allows you to adjust the voltage range that the chip measures to be as close as possible to the actual physical voltage range that the input will use. The chip can be configured for the following ranges:

| Value | Range |

|---|---|

| 0.256 | +/- 0.256V |

| 0.512 | +/- 0.512V |

| 1.024 | +/- 1.024V |

| 2.048 | +/- 2.048V |

| 4.096 | +/- 4.096V |

| 6.144 | +/- 6.144V |

You can set this to any numeric value, but the chip can only accept the values listed above, so Pinscape will choose the closest match (the one with the smallest numeric difference from the value you specify) if you enter a value not listed.

The default is 4.096, which is suitable for most Pico applications, where the analog voltage you're measuring is in the same range as the Pico's GPIO port logical range, 0V to 3.3V. If you're connecting a device that uses a wider or smaller range of voltages, you can improve the resolution of the measurements by changing the range setting.

It won't damage the chip if the actual voltage input exceeds the full-scale range. The chip physically tolerates voltages on the AINx inputs from 0V to slightly over the supply voltage, usually 3.3V, regardless of the amplifier range setting. A voltage that exceeds the amplifier range setting simply clips to the maximum digital readout value (+32767).

Important: The voltageRange setting only sets the internal range on the input amplifier stage within the chip. It doesn't make it safe for the input voltage at the AINx pin to exceed the 0 to 3.3V supply voltage range. Never apply a voltage below 0V or above 3.3V to an AINx pin. Refer to the Absolute Maximum Ratings section in the ADS1115 data sheet for details on the safe operating ranges.

Configures an AEDR-8300 linear quadrature encoder chip. These chips can be used as plunger position sensors. Refer to the setup instructions in the Pinscape Build Guide.

The Pico GPIO port number connected to the chip's channel "A" pin.

The Pico GPIO port number connected to the chip's channel "B" pin.

Defines the logical button inputs, which map physical and virtual button inputs to actions, such as sending keystrokes to the PC. Each entry in this list is an object that defines one logical button. Each logical button definition has a source, which specifies the physical or virtual input that triggers the action, and an action, which specifies what happens when you press the source button. Each logical button can also have a "type", which specifies how changes to the physical input are interpreted. The standard type is "pushbutton", which is an ordinary momentary switch that carries out its action as long as you're physically pressing the button, and stops as soon as you release it. Other types include "hold" buttons, which only carry out their action after being held down for a defined interval; "pulse" buttons, which only carry out their action once when pushed, rather than continuously while being held down; "toggle" buttons, which switch between OFF and ON each time they're pushed, rather than staying on only while being held down; and "shift" buttons, which let you assign multiple meanings to other buttons, analogous to the keys like SHIFT, CTRL, and ALT on a PC keyboard.

Buttons are defined using two main abstractions:

Each buttons[] entry's main job is to connect a source and an action. When the source records an activation (pressing the physical button, receiving the IR command, crossing an accelerometer threshold), the action is carried out.

The same source can be used more than once (that is, in more than one buttons[] array entry). This lets you map a single physical input to multiple actions to be carried out, such as sending both a keyboard key press and a joystick button press to the PC whenever the button is pressed. Macros can also be used to carry out multiple effects for each button press, with the additional feature that macros can control the timing of the sub-actions.

This is an object that specifies the action that's triggered when the logical button is activated by its input source.

This specifies which type of action to take when the button is activated.

| Type | Description |

|---|---|

| "key" | Keyboard key press |

| "media" | Media controller key press |

| "gamepad" | Gamepad button press |

| "xInput" | XBox controller button press |

| "openPinDev" | Open Pinball Device button press |

| "reset" | Reset the Pico |

| "nightmode" | Toggle Night Mode |

| "plungercal" | Start plunger calibration |

| "IR" | Send an IR command on the IR transmitter |

| "macro" | Execute a macro |

| "none" | Do nothing |

Sets up the button to transmit a remote control command through the IR emitter when pressed.

If set to true, the IR command is sent repeatedly as long as the logical button is activated. If false (the default), the command is only sent once when the logical button is pressed, no longer how long the button remains activated.

The IR command code to send when the button is pressed, expressed as a string in the Pinscape universal IR code format. The easiest way to determine the right code to use for a particular button press is to use the Pinscape Config Tool's IR & TV ON window, which displays codes as they're received on the sensor. Open the window and press the remote control button whose code you want to determine, and it should appear in the list of commands received. Now simply copy the code from that list into the type string here.

Sets up the button to act as a gamepad button on the PC. Activating the logical button presses the associated gamepad button.

The gamepad button number to press when the logical button is activated, 1 to 32, or a string from the list below.

| String Value | Description |

|---|---|

| hat-down | Hat switch "down" (south) button |

| hat-left | Hat switch "left" (west) button |

| hat-right | Hat switch "right" (east) button |

| hat-up | Hat switch "up" (north) button |

This sets up the button to act as a keyboard key on the PC. When the button is activated, Pinscape sends the designated key press, and keeps sending it as long as the button remains activated.

To use keyboard actions, make sure that the USB keyboard device is enabled via the keyboard.enable property.

A type="key" action is a very literal emulation of a physical USB keyboard key press, which means that it can send any one key, but only the one. If you want send a combination of key presses involving modifier keys, such as Ctrl+A or Shift+Ctrl+End, you need a macro.

Specifies the keyboard key to send when the button is pressed. This can be a "usage number" from the USB HID keyboard page, from 1 to 255, or it can be a string giving the name of the key, from the set listed below.

Alternatively, the key can be a "chord", which is a combination of keys with modifiers such as Ctrl, Shift, and Alt. Chords are written using the Microsoft convention, as in "Ctrl+Shift+F1" to mean holding down the Ctrl and Shift keys while pressing the F1 key. When you define a chord in this notation, the software internally converts the "key" action into a "macro" action, and automatically programs the macro with a series of "key" steps matching the keys you list in the chord, with all of the steps starting as soon as you press the source button, and all of the steps remaining in effect until you release the source button. So the macro steps are set to { start: 0, duration: "hold" }.

| Key name | USB usage | Description |

|---|---|---|

| "a" | 0x04 | Keyboard a and A |

| "b" | 0x05 | Keyboard b and B |

| "c" | 0x06 | Keyboard c and C |

| "d" | 0x07 | Keyboard d and D |

| "e" | 0x08 | Keyboard e and E |

| "f" | 0x09 | Keyboard f and F |

| "g" | 0x0A | Keyboard g and G |

| "h" | 0x0B | Keyboard h and H |

| "i" | 0x0C | Keyboard i and I |

| "j" | 0x0D | Keyboard j and J |

| "k" | 0x0E | Keyboard k and K |

| "l" | 0x0F | Keyboard l and L |

| "m" | 0x10 | Keyboard m and M |

| "n" | 0x11 | Keyboard n and N |

| "o" | 0x12 | Keyboard o and O |

| "p" | 0x13 | Keyboard p and P |

| "q" | 0x14 | Keyboard q and Q |

| "r" | 0x15 | Keyboard r and R |

| "s" | 0x16 | Keyboard s and S |

| "t" | 0x17 | Keyboard t and T |

| "u" | 0x18 | Keyboard u and U |

| "v" | 0x19 | Keyboard v and V |

| "w" | 0x1A | Keyboard w and W |

| "x" | 0x1B | Keyboard x and X |

| "y" | 0x1C | Keyboard y and Y |

| "z" | 0x1D | Keyboard z and Z |

| "1" | 0x1E | Keyboard 1 and ! |

| "!" | 0x1E | Keyboard 1 and ! |

| "2" | 0x1F | Keyboard 2 and @ |

| "@" | 0x1F | Keyboard 2 and @ |

| "3" | 0x20 | Keyboard 3 and # |

| "#" | 0x20 | Keyboard 3 and # |

| "4" | 0x21 | Keyboard 4 and $ |

| "$" | 0x21 | Keyboard 4 and $ |

| "5" | 0x22 | Keyboard 5 and % |

| "%" | 0x22 | Keyboard 5 and % |

| "6" | 0x23 | Keyboard 6 and ^ |

| "^" | 0x23 | Keyboard 6 and ^ |

| "7" | 0x24 | Keyboard 7 and & |

| "&" | 0x24 | Keyboard 7 and & |

| "8" | 0x25 | Keyboard 8 and * |

| "*" | 0x25 | Keyboard 8 and * |

| "9" | 0x26 | Keyboard 9 and ( |

| "(" | 0x26 | Keyboard 9 and ( |

| "0" | 0x27 | Keyboard 0 and ) |

| ")" | 0x27 | Keyboard 0 and ) |

| "return" | 0x28 | Keyboard Return (ENTER) |

| "enter" | 0x28 | Keyboard Return (ENTER) |

| "esc" | 0x29 | Keyboard ESCAPE |

| "escape" | 0x29 | Keyboard ESCAPE |

| "backspace" | 0x2A | Keyboard DELETE (Backspace) |

| "bksp" | 0x2A | Keyboard DELETE (Backspace) |

| "tab" | 0x2B | Keyboard Tab |

| "space" | 0x2C | Keyboard Spacebar |

| "spacebar" | 0x2C | Keyboard Spacebar |

| "-" | 0x2D | Keyboard - and (underscore) |

| "_" | 0x2D | Keyboard - and (underscore) |

| "hyphen" | 0x2D | Keyboard - and (underscore) |

| "minus" | 0x2D | Keyboard - and (underscore) |

| "=" | 0x2E | Keyboard = and + |

| "+" | 0x2E | Keyboard = and + |

| "equals" | 0x2E | Keyboard = and + |

| "[" | 0x2F | Keyboard [ and { |

| "{" | 0x2F | Keyboard [ and { |

| "lbrack" | 0x2F | Keyboard [ and { |

| "lbrace" | 0x2F | Keyboard [ and { |

| "]" | 0x30 | Keyboard ] and } |

| "}" | 0x30 | Keyboard ] and } |

| "rbrack" | 0x30 | Keyboard ] and } |

| "rbrace" | 0x30 | Keyboard ] and } |

| "\\" | 0x31 | Keyboard \ and | |

| "||" | 0x31 | Keyboard \ and | |

| "backslash" | 0x31 | Keyboard \ and | |

| ";" | 0x33 | Keyboard ; and : |

| ":" | 0x33 | Keyboard ; and : |

| "semicolon" | 0x33 | Keyboard ; and : |

| "colon" | 0x33 | Keyboard ; and : |

| "'" | 0x34 | Keyboard ' and " |

| "\"" | 0x34 | Keyboard ' and " |

| "," | x36 | Keyboard , and < |

| "<" | 0x36 | Keyboard , and < |

| "comma" | x36 | Keyboard , and < |

| "." | 0x37 | Keyboard . and > |

| ">" | 0x37 | Keyboard . and > |

| "period" | 0x37 | Keyboard . and > |

| "dot" | 0x37 | Keyboard . and > |

| "/" | 0x38 | Keyboard / and ? |

| "?" | 0x38 | Keyboard / and ? |

| "slash" | 0x38 | Keyboard / and ? |

| "caps lock" | 0x39 | Keyboard Caps Lock |

| "capslock" | 0x39 | Keyboard Caps Lock |

| "f1" | 0x3A | Keyboard F1 |

| "f2" | 0x3B | Keyboard F2 |

| "f3" | 0x3C | Keyboard F3 |

| "f4" | 0x3D | Keyboard F4 |

| "f5" | 0x3E | Keyboard F5 |

| "f6" | 0x3F | Keyboard F6 |

| "f7" | 0x40 | Keyboard F7 |

| "f8" | 0x41 | Keyboard F8 |

| "f9" | 0x42 | Keyboard F9 |

| "f10" | 0x43 | Keyboard F10 |

| "f11" | 0x44 | Keyboard F11 |

| "f12" | 0x45 | Keyboard F12 |

| "print screen" | 0x46 | Keyboard PrintScreen |

| "printscreen" | 0x46 | Keyboard PrintScreen |

| "prntscrn" | 0x46 | Keyboard PrintScreen |

| "prtscr" | 0x46 | Keyboard PrintScreen |

| "scrolllock" | 0x47 | Keyboard Scroll Lock |

| "scroll lock" | 0x47 | Keyboard Scroll Lock |

| "pause" | 0x48 | Keyboard Pause |

| "ins" | 0x49 | Keyboard Insert |

| "insert" | 0x49 | Keyboard Insert |

| "home" | 0x4A | Keyboard Home |

| "page up" | 0x4B | Keyboard PageUp |

| "pageup" | 0x4B | Keyboard PageUp |

| "pgup" | 0x4B | Keyboard PageUp |

| "del" | 0x4C | Keyboard Delete Forward |

| "delete" | 0x4C | Keyboard Delete Forward |

| "end" | 0x4D | Keyboard End |

| "page down" | 0x4E | Keyboard PageDown |

| "pagedown" | 0x4E | Keyboard PageDown |

| "pagedn" | 0x4E | Keyboard PageDown |

| "pgdn" | 0x4E | Keyboard PageDown |

| "right" | 0x4F | Keyboard RightArrow |

| "right arrow" | 0x4F | Keyboard RightArrow |

| "left" | 0x50 | Keyboard LeftArrow |

| "left arrow" | 0x50 | Keyboard LeftArrow |

| "down" | 0x51 | Keyboard DownArrow |

| "down arrow" | 0x51 | Keyboard DownArrow |

| "up" | 0x52 | Keyboard UpArrow |

| "up arrow" | 0x52 | Keyboard UpArrow |

| "numlock" | 0x53 | Keypad Num Lock and Clear |

| "num lock" | 0x53 | Keypad Num Lock and Clear |

| "clear" | 0x53 | Keypad Num Lock and Clear |

| "keypad /" | 0x54 | Keypad / |

| "keypad *" | 0x55 | Keypad * |

| "keypad -" | 0x56 | Keypad - |

| "keypad +" | 0x57 | Keypad + |

| "keypad enter" | 0x58 | Keypad ENTER |

| "keypad 1" | 0x59 | Keypad 1 and End |

| "keypad 2" | 0x5A | Keypad 2 and Down Arrow |

| "keypad 3" | 0x5B | Keypad 3 and PageDn |

| "keypad 4" | 0x5C | Keypad 4 and Left Arrow |

| "keypad 5" | 0x5D | Keypad 5 |

| "keypad 6" | 0x5E | Keypad 6 and Right Arrow |

| "keypad 7" | 0x5F | Keypad 7 and Home |

| "keypad 8" | 0x60 | Keypad 8 and Up Arrow |

| "keypad 9" | 0x61 | Keypad 9 and PageUp |

| "keypad 0" | 0x62 | Keypad 0 and Insert |

| "keypad ." | 0x63 | Keypad . and Delete |

| "application" | 0x65 | Keyboard Application |

| "power" | 0x66 | Keyboard Power |

| "keypad =" | 0x67 | Keypad = |

| "f13" | 0x68 | Keyboard F13 |

| "f14" | 0x69 | Keyboard F14 |

| "f15" | 0x6A | Keyboard F15 |

| "f16" | 0x6B | Keyboard F16 |

| "f17" | 0x6C | Keyboard F17 |

| "f18" | 0x6D | Keyboard F18 |

| "f19" | 0x6E | Keyboard F19 |

| "f20" | 0x6F | Keyboard F20 |

| "f21" | 0x70 | Keyboard F21 |

| "f22" | 0x71 | Keyboard F22 |

| "f23" | 0x72 | Keyboard F23 |

| "f24" | 0x73 | Keyboard F24 |

| "execute" | 0x74 | Keyboard Execute |

| "help" | 0x75 | Keyboard Help |

| "menu" | 0x76 | Keyboard Menu |

| "select" | 0x77 | Keyboard Select |

| "stop" | 0x78 | Keyboard Stop |

| "again" | 0x79 | Keyboard Again |

| "undo" | 0x7A | Keyboard Undo |

| "cut" | 0x7B | Keyboard Cut |

| "copy" | 0x7C | Keyboard Copy |

| "paste" | 0x7D | Keyboard Paste |

| "find" | 0x7E | Keyboard Find |

| "mute" | 0x7F | Keyboard Mute |

| "volup" | 0x80 | Keyboard Volume Up |

| "voldown" | 0x81 | Keyboard Volume Down |

| "voldn" | 0x81 | Keyboard Volume Down |

| "keypad ," | 0x85 | Keypad Comma |

| "keypad comma" | 0x85 | Keypad Comma |

| "keypad 00" | 0xB0 | Keypad 00 |

| "keypad 000" | 0xB1 | Keypad 000 |

| "ctrl" | 0xE0 | Keyboard LeftControl |

| "left ctrl" | 0xE0 | Keyboard LeftControl |

| "left control" | 0xE0 | Keyboard LeftControl |

| "shift" | 0xE1 | Keyboard LeftShift |

| "left shift" | 0xE1 | Keyboard LeftShift |

| "alt" | 0xE2 | Keyboard LeftAlt |

| "left alt" | 0xE2 | Keyboard LeftAlt |

| "gui" | 0xE3 | Keyboard Left GUI |

| "left gui" | 0xE3 | Keyboard Left GUI |

| "right ctrl" | 0xE4 | Keyboard RightControl |

| "right control" | 0xE4 | Keyboard RightControl |

| "right shift" | 0xE5 | Keyboard RightShift |

| "right alt" | 0xE6 | Keyboard RightAlt |

| "right gui" | 0xE7 | Keyboard Right GUI |

This sets up a macro button, which performs a series of timed actions when activated.

A macro can carry out any sequence of other basic actions, with the exception that it can't invoke another macro. This allows for all sorts of complex actions, such as pressing chords of keyboard keys (Ctrl+Shift+A, say), typing in a sequence of keystrokes to enter a command, pushing a joystick button and a keyboard key at the same time, or entering a series of joystick button presses.

The macro is defined as a series of steps to perform. Each step has a starting time relative to the previous step's starting time. This can be zero, in which case the step starts at the same time as the previous step. Each step also has a duration, which specifies how long the action goes on; for example, for a key press action, this specifies how long the key is held down.

A macro can be set to repeat its series of steps as long as the physical button is held down, or to just execute it once and then stop, even if the user continues to press the button indefinitely. Similarly, you can specify whether the macro runs to completion once started, even if the user doesn't keep holding down the button long enough to complete the macro, or if the macro stops in the middle of what it's doing when the user releases the button.

If set to true (the default), the macro will start over at the beginning if the button is still being held down after the last step finishes. If set to false, the macro only runs once, stopping after the last step even if the button is still being held down.

If set to true (the default), the macro runs through all of its steps every time the button is pressed, even if the button isn't held down as long as it takes to finish running through the steps. If set to false, the macro stops as soon as the button is released, even if there are still more steps that haven't been completed yet.

An array of objects giving the list of action steps to carry out when the button is pressed. Each step lists one action, with a starting time and a duration. Each step's action is an object with exactly the same properties as the main "action" property for a button, so in effect, a macro carries out the equivalent of a series of timed button presses. But the "buttons" being pressed don't have to exist outside of the macro, since the macro contains the entire definition of each action.

The action to perform. This is the same sort of action object that you can define for a button in its "action" property, with all of the same properties, except that it can't contain another macro action.

The duration of the step, in milliseconds, or the special string value "hold". This is the amount of time that the step's action remains activated. A step can remain activated even while later steps are started; new steps don't have to wait for earlier steps to finish.

If this is set to "hold", it means that the step remains in effect until the button that activated the macro is released. This makes it easy to define a macro that expresses a "key chord" such as Ctrl+Alt+X, by letting you program the macro to hold all three key actions as long as the button is being pressed.

The starting time of the step, as the number of milliseconds to wait after the start of the previous step. If this is zero (the default), this step starts simultaneously with the previous step. Note that the reference point is the starting time of the prior step, which lets you start multiple steps at the same time - a new step doesn't have to wait until the prior step finishes.

This sets up the button to act as a "media controller" key on the PC. These are essentially just an extended set of keyboard keys associated with media functions, like "Play" and "Pause", which appear on some keyboards as an extra row of keys above the function keys.

To use media key actions, make sure that the USB keyboard device is enabled via the keyboard.enable property.

Specifies the media key to send when the button is pressed. This is a string naming one of the special media keys that Pinscape can send.

| Key name | Description |

|---|---|

| "mute" | Mute audio |

| "volUp" | Audio volume up |

| "volDn" | Audio volume down |

| "next" | Skip to next media track |

| "prev" | Skip to previous media track |

| "stop" | Stop media playback |

| "play" | Start media playback |

| "eject" | Eject media (note: Windows ignores this key) |

Sets up the button as a Night Mode control. Pressing the button toggles the current Night mode setting.

This sets up a virtual button that accepts input but doesn't perform any action.

This sets up the button to send input through the Open Pinball Device interface.

To use this type of button mapping, the Open Pinball Device HID interface must be enabled via the openPinballDevice.enabled property.

Sets the Open Pinball Device virtual button to activate when this physical button is pressed.

The Open Pinball Device interface provides two kinds of buttons: a set of 32 "generic" numbered buttons, identified simply as button numbers 1 through 32; and a collection of pre-defined, named "pinball" buttons, with specific assigned functions that map to the standard functions that most of the PC pinball simulators use, such as "Start Game", "Launch Ball", "Left Flipper", and so on. The generic numbered buttons and the name pinball buttons are completely independent of one another, so this gives you a total of 59 assignable buttons: 32 generic numbered buttons plus the 27 named buttons.

To assign an action to a generic button, set button to a number from 1 to 32. These buttons are comparable to gamepad buttons, in that they don't have any pre-assigned meanings; they're just generic buttons that you can assign to a selected function in each PC program you're using. You have to go into each program's setup options or configuration file to map the numbered buttons to in-program functions. In Visual Pinball, for example, the generic Open Pinball Device buttons are treated exactly like joystick buttons, so you assign the VP function of generic button #1 by going into VP's Keys dialog and assigning one of the command keys to Joystick Button #1.

The pinball buttons are a separate set of virtual buttons that are pre-assigned to the common functions found in almost all of the pinball simulator programs. The nice thing about the pinball buttons is that the compatible simulators have built-in mappings for these, so you don't have to manually configure them in each simulator. Just assign a physical button to "start", and it'll automatically act as the Start button in every compatible simulator. To set up a pinball button action, use one of the strings shown below for the button value.

| Button name | Description |

|---|---|

| "start" | Start button (start a new game) |

| "exit" | Exit button (exit the simulator) |

| "coin 1" | Left coin slot |

| "coin 2" | Middle coin slot |

| "coin 3" | Right coin slot |

| "coin 4" | Fourth coin slot or bill acceptor |

| "extra ball" | Extra Ball/Buy-in button |

| "launch" | Launch Ball button and/or button-operated plunger |

| "fire" | Fire button (button on the top of the lock bar on many later Stern machines, for activating game-specific features) |

| "tilt bob" | Tilt bob switch (triggers a Tilt condition in the game; not for simulated nudge inputs) |

| "slam tilt" | Slam tilt switch (an additional type of tilt switch inside the coin door on many real machines) |

| "coin door" | Coin door open/closed position sensor switch |

| "service cancel" | Cancel/Exit button, part of the service/operator control panel located inside the coin door |

| "service down" | Down/Previous button, part of the service controls |

| "service up" | Up/Next button, part of the service controls |

| "service enter" | Enter/Select button, part of the service controls|

| "left magnasave" | Left MagnaSave button (an extra flipper-like button adjacent to the regular flipper button on some machines) |

| "right magnasave" | Right MagnaSave button |

| "left nudge" | Manual nudge input, simulating a nudge from the left side |

| "forward nudge" | Manual nudge input, simulating a nudge pushing forward |

| "right nudge" | Manual nudge input, simulating a nudge from the right side |

| "volume up" | Audio volume up (controls the audio volume within the simulator; doesn't usually affect the system-wide volume level) |

| "volume down" | Audio volume down |

| "left flipper" | Left flipper button |

| "left flipper 2" | Secondary left flipper switch, for stacked double switches used in many machines with upper |

| "right flipper" | Right flipper button |

| "right flipper 2" | Right secondary flipper switch, for stacked double switches |

The flipper buttons are split into "main" and "secondary" switches. These are designed to replicate the stacked leaf switches found in many mechanical pinball machines that feature upper and lower flippers. Both switches in the stack are operated by a single flipper button, so there's just one left button and one right button. Pushing the button part-way in closes the outer, "main" switch, which operates the main lower flipper on that side. Continuing to press the button further in eventually also closes the inner "secondary" switch in the stack, which operates the upper flipper on that side. Many mechanical pinballs are set up this way to allow players to operate the upper flipper on each side separately from the lower flipper, so that advanced players can hold a ball trapped in a lower flipper, while separately using the upper flipper to take a shot with another ball during multiball play. If your pin cab includes the stacked switches, you can set them up as separate physical button inputs, and map their actions to the corresponding main and secondary switches here.

Sets up the button to act as the plunger calibration mode control button. Pressing and holding the button for about two seconds activates calibration mode. Once calibration mode is initiated, the calibration runs for a set time (about 15 seconds) to gather data on the range of sensor readings over the plunger's mechanical travel distance. During this period, the user should pull the plunger all the way back, hold it briefly, release it, allow it to come to rest, and then repeat a few times. When the timed interval ends, the new calibration settings automatically go into effect.

Activating the button resets the Pico, optionally activating its Boot Loader mode.

The time the button must be held down, in milliseconds, before the reset occurs. Default is 2000ms (2 seconds).

Reset mode. "normal" resets the Pico and restarts the Pinscape firmware. "bootloader" puts the Pico into its native Boot Loader moder, where it presents itself as a virtual thumb drive for installing new firmware.

Sets up the button to act as an XBox controller button on the PC. Activating the logical button presses the associated XBox controller button.

The XBox controller button to press when the logical button is activated.

| Key name | Description |

|---|---|

| "up" | Direction pad UP button |

| "down" | Direction pad DOWN button |

| "left" | Direction pad LEFT button |

| "right" | Direction pad RIGHT button |

| "start" | START button |

| "back" | BACK button |

| "l3" | Left joystick click |

| "r3" | Right joystick click |

| "lb" | Left bumper button (back of controller) |

| "rb" | Right bumper button (back of controller) |

| "xbox" | XBOX button |

| "a" | A button |

| "b" | B button |

| "x" | X button |

| "y" | Y button |

Assigns the button a name, which you can use to refer to the button elsewhere in the configuration, such as in a computed output source (via the button() source type).

Marks the button as a USB wake-up button. If this is true, pressing the button while the PC is in sleep mode will send a USB wake-up signal to the PC. (The PC has to be configured to obey wake-up signals, which is usually the default on Windows PCs, but it might require modifying settings in your Windows power preferences and possibly the PC's BIOS.)

For a button with type="shift", this sets the bits that are added into the "global shift state" when the button is pressed.

For any other button type, this sets the value that the following formula must match each time the button is pressed for the button to activate:

global-shift-state AND shiftMask == shiftBits

See shiftMask for more details on how the shift bits and shift mask work together to determine how the button reacts to modifier buttons.

Sets the bits in the "global shift state" that the button is sensitive to.

When the button is pressed, Pinscape combines this button's shiftMask with the current global shift state using a bitwise AND. It then compares the result to the button's shiftBits. If the two values are equal, the press activates the button. Otherwise, the press is ignored.

This can be used to make a button sensitive to one or more modifier buttons, or to make it insensitive to all of the modifier buttons. The table below lists some basic formulas for how to set this up (in combination with shiftBits) to get different effects. For the examples in the table, let's say that we've set up the following shift buttons:

You can easily extend this idea to add as many more shift buttons as you need, up to a total of 32 of them. Just keep picking the next higher bit value for each added button: 0x0004, 0x0008, 0x0010, etc.

| Goal | shiftMask | shiftBits | Description |

|---|---|---|---|

| Ignores all shift buttons | 0 | 0 | This button always works the same way, regardless of which shift buttons are pressed. Since X AND 0 = 0 for all X, the result of shiftMask AND global-shift-state is always 0, so it always matches the zero in shiftBits, and the button always operates. |

| Operates when EXTRA BALL is not pressed | 0x0001 | 0x0000 | This button only takes effect when the EXTRA BALL shift button is NOT pressed. When EXTRA BALL is pressed, the global shift state contains EXTRA BALL's shiftBits bits, 0x0001, so shiftMask AND global-shift-state equals 0x0001. This is not equal to shiftBits, so the button ignores the press. When EXTRA BALL isn't pressed, the global shift state doesn't contain bit 0x0001, so shiftMask AND global-shift-state equals 0, which equals the shiftBits value, so the button activates. |

| Operates when EXTRA BALL is pressed | 0x0001 | 0x0001 |

This button only takes effect when the EXTRA BALL shift button is pressed.

When EXTRA BALL is pressed, the global shift state contains EXTRA BALL's

shiftBits bits, 0x0001, so shiftMask AND global-shift-state equals 0x0001.

This equals shiftBits, so the button activates.

When EXTRA BALL isn't pressed, the global shift state doesn't

contain bit 0x0001, so shiftMask AND global-shift-state equals 0, which

is unequal to shiftBits, so the button ignores the press.

Note that this button ignores the EXIT button state - it only pays attention to the EXTRA BALL state. |

| Operates when both EXTRA BALL and EXIT are pressed | 0x0003 | 0x0003 | This is how you create a chord analogous to Alt+Ctrl+X on a PC keyboard. This button takes effect only when BOTH shift keys are pressed. This works because the shiftMask contains the combination of shift bits for both of the modifier keys - 0x0001 OR 0x0002 = 0x0003. When we figure global-shift-state AND shiftMask, we get 0x0003 (the shiftBits value) only if the global shift state contains both of those bits, so the button only operates if both modifiers are pressed. |

| Operates when EXTRA BALL is pressed but not EXIT | 0x0003 | 0x0001 | This is the flip side of the EXTRA BALL + EXIT case above, setting the button so that it only operates when one of the modifier keys is pressed, but not both. shiftMask contains the bits for both of the shift keys, but shiftBits only contains the bits for EXTRA BALL, so the button will only operate when EXTRA BALL is pressed and EXIT is not. (To define a button that operates when EXIT is pressed but not EXTRA BALL, change shiftBits to 0x0002, the EXIT shift bits.) |

shiftMask has no effect for a button that's defined with type "shift". Shift buttons always mean one thing and always ignore other shift buttons.

Specifies the physical device port or data source that serves as the input for the logical button state. For a physical button, this is a hardware port connected to the button switch, such as a Pico GPIO port or a shift register input port. Buttons can also take their input from software sources, such as the plunger and nudge subsystems, or the IR remote control receiver.

"high" for a button whose port reads logic "1" when pressed, "low" for a port that reads logic "0". For physical inputs like GPIO ports and shift register inputs, a port is active-high if the switch connects the port to 3.3V when the button is pressed, and active-low if it connects to GND when pressed. The standard wiring is "active low", where one terminal of the switch is connected to the input port, and the other terminal is connected to GND. If this property is omitted, the default is active-low.

The source type. See the source types below for more details.

Sets the button's input source to a port on a 74HC165 chip. The 74HC165 is an input shift-register chip with 8 digital on/off input ports, which can be used as button inputs. Multiple 74HC165 chips can be daisy-chained, letting you add more input ports in groups of 8 as needed.

The daisy chain number. This is an index into the "74hc165:" array in the JSON configuration file, selecting which daisy chain this button is associated with. If you only have a single chain (which is almost always the case - it's rare to configure more than one), you can omit this, and the system will know you mean to use the one-and-only.

The chip number on the daisy chain. The first chip on the chain (the one attached directly to the Pico) is number 0, the second is number 1, and so on. If you include this, then you only have to give the port number relative to the chip; if you omit it, the port number is specified in terms of the whole chain.

Sets the debouncing "OFF" time for the switch input, in microseconds. This is the counterpart of debounceTimeOn, for when the switch transitions to OFF (releasing the button). Switches typically settle into the OFF state more quickly than into the ON state, so this can usually be set to a shorter value than the ON time. The default is 1000 microseconds (1 millisecond).

Sets the debouncing "ON" time for the switch input, in microseconds. Most physical switches "bounce" when switching between ON and OFF states, which means that the voltage level on the switch oscillates very rapidly for a brief time after the moment of contact. The brief instability in the signal can cause odd behavior in some host software reading the switch state; for example, if a button is mapped to keyboard input, the bounce effect might cause the key input to be repeated several times for a single button press. Debouncing refers to any sort of filtering that suppresses the oscillations after an on/off transition. Pinscape Pico debounces inputs by ignoring any further on/off changes for a brief time after each valid on/off change. This parameter sets the duration of that suppression time after an ON transition (from OFF to ON, when the button is pressed). The default value is 1500 microseconds (1.5 millisecond), which is long enough to suppress bounce in typical microswitches. If you experience any spurious input from a button, especially repeated inputs for a single button press, you can try increasing this. Longer values have the disadvantage that they limit the rate at which intentional fast taps can be processed.

Sets the debouncing low-pass filter time for falling edges, in microseconds. This is the minimum amount of time that the 74HC165 port must remain in the LOW state after a "falling edge" - a HIGH-to-LOW voltage transition on the port - before Pinscape will recognize the new LOW state. This is designed to filter out random electrical noise on the input, by requiring that the new LOW level remain in effect continuously for a minimum amount of time before it's treated as legitimate.

The FALL time applies to physical HIGH-to-LOW voltage transitions on the port, regardless of the active-high/low setting on the port.

Unlike the debounceTimeOn/Off "hold" times, the low-pass filter adds latency to input recognition, since the software won't recognize a physical button press until the low-pass filter time elapses. This value should therefore be kept as small as possible. The default is 0, which doesn't apply any low-pass filtering at all. For many switches, the latency-free debounceTimeOn/Off settings are all you need to eliminate switch bounce artifacts, but some switches have enough intrinsic noise that low-pass filtering is also required.

Sets the debouncing low-pass filter time for rising edges, in microseconds. This is the minimum amount of time that the 74HC165 port must remain in the HIGH state after a "rising edge" - a LOW-to-HIGH voltage transition on the port - before Pinscape will recognize the new HIGH state. This is designed to filter out random electrical noise on the input, by requiring that the new HIGH level remain in effect continuously for a minimum amount of time before it's treated as legitimate.

The RISE time applies to physical LOW-to-HIGH voltage transitions on the port, regardless of the active-high/low setting on the port.

Unlike the debounceTimeOn/Off "hold" times, the low-pass filter adds latency to input recognition, since the software won't recognize a physical button press until the low-pass filter time elapses. This value should therefore be kept as small as possible. The default is 0, which doesn't apply any low-pass filtering at all. For many switches, the latency-free debounceTimeOn/Off settings are all you need to eliminate switch bounce artifacts, but some switches have enough intrinsic noise that low-pass filtering is also required.

The input pin on the selected daisy chain. If you specify the "chip" property to select a chip on the chain, the port should be specified as simply "A" to "H", corresponding to the pin labels used in the chip's data sheet. To make things more compact, you can skip the "chip" property and instead include it here, as in "0A" for pin A on the first chip on the chain, or "1H" for pin H on the second chip.

You can also use the NXP data sheet notation, where the ports are labeled D0 through D7 (instead of A through H, as the TI data sheet would have it). The chip number prefix works here, too: "1D3" for pin D3 on chip index 1 (the second chip on the daisy chain).

Alternatively, you can specify this as a pin number, 0-7 on each chip corresponding to pin A-H. If you omit the chip number, you can specify ports 0-7 for the first chip on the chain, 8-15 for the second chip, 16-23 for the third, and so on. I think the string notation is clearer, though.

Sets up the button as an IR command receiver. The button will trigger its action when the specified IR command is receive on the IR remote control sensor. An IR receiver must be attached and configured for this to work, obviously.

The IR command code that triggers the button. This is a string in the Pinscape universal IR code format. The easiest way to determine the code that goes with a particular button is to use the Pinscape Config Tool's IR & TV ON tester window, which shows command codes for commands received while the window is open. Just copy a command code from that window into the "code" property.

This is a sort of book-end to the latchTime property. This sets the amount of time to wait after the command is received before the ON time for the logical button will be extended with repeats of the code. This is meant to help distinguish short taps on the button from long presses. The reason this is needed is that most IR remote controls start transmitting repeats very quickly, so quickly that a quick tap on a button can often send two or three repeats of the code. With the latchTime property extending the ON time after each code, the repeats can make a short tap on the physical IR remote button turn into a much longer hold on the logical button, which might not produce the right effect on the PC. The firstRepeatDelay is intended to help with that by ignoring initial repeats for a short time.

The "latching" time for the command, in milliseconds (1000 milliseconds equals one second). The button stays activated for this amount of time each time the code is received. This is designed to make the logical button's action on the PC stay on continuously when you're holding down the button on the remote. IR remotes don't have a direct way to tell the receiver that the button is being held down; instead, they transmit the same code repeatedly at short intervals. So if you hold down the button on the remote, Pinscape will see a series of repeated codes. The latchTime tells Pinscape to keep holding the logical button ON for a little while after each code, to see if a repeat of the code is forthcoming. If you make this interval long enough that the codes overlap, the logical button will remain on continuously as long as you're holding down the remote button. That smooths out the "pulse train" from the IR remote and turns it into what looks like a push-and-hold on the logical button.

Sets the button's input source as the BOOTSEL button - the little button on top of the Pico that's normally used to put the Pico into its Boot Loader mode during a reset. This button can be used as an ordinary input because its special Boot Loader function only takes effect while the Pico is resetting.

Defines the button as a GPIO input, wired to a physical switch through a Pico GPIO port.

Sets the debouncing "OFF" time for the switch input, in microseconds. This is the counterpart of debounceTimeOn, for when the switch transitions to OFF (releasing the button). Switches typically settle into the OFF state more quickly than into the ON state, so this can usually be set to a shorter value than the ON time. The default is 1000 microseconds (1 millisecond).

Sets the debouncing ON hold time for the GPIO input, in microseconds. Most physical switches "bounce" when switching between ON and OFF states, which means that the voltage level on the switch oscillates very rapidly for a brief time after the moment of contact. The brief instability in the signal can cause odd behavior in some host software reading the switch state; for example, if a button is mapped to keyboard input, the bounce effect might cause the key input to be repeated several times for a single button press. Debouncing refers to any sort of filtering that suppresses the oscillations after an on/off transition. Pinscape Pico debounces inputs by ignoring any further on/off changes for a brief time after each valid on/off change. This parameter sets the duration of that suppression time after an ON transition (from OFF to ON). The default value is 1500 microseconds (1.5 milliseconds), which is long enough to suppress bounce in typical microswitches. If you experience any spurious input from a button, especially repeated inputs for a single button press, you can try increasing the time.

If true, the port will be configured to enable hardware interrupts on logic-level changes on the port's voltage input, and the interrupt handler will record the time of each transition in an internal log. Software on the PC host can retrieve the event log and use it to analyze the latency (elapsed time) between physical button presses and the corresponding HID reports to the PC. The Pico can service hardware interrupts with very low latency, on the order of 200 nanoseconds, and records the event time with microsecond precision, so the host can measure HID latencies with very good precision.

This option is only intended for use with performance measuring tools on the PC. It doesn't do anything useful in ordinary operation with a pinball simulator, and it adds a small amount of overhead on the Pico side to service the interrupts and reserve memory for the log buffer, so it's best to disable it when not running performance tests.

Sets the GPIO port for the button input.

Sets the debouncing low-pass filter time for falling edges, in microseconds. This is the minimum amount of time that the GPIO port must remain in the LOW state after a "falling edge" - a HIGH-to-LOW voltage transition on the GPIO port - before Pinscape will recognize the new LOW state. This is designed to filter out random electrical noise on the input, by requiring that the new LOW level remain in effect continuously for a minimum amount of time before it's treated as legitimate.

The FALL time applies to physical HIGH-to-LOW voltage transitions on the port, regardless of the active-high/low setting on the port.

Unlike the debounceTimeOn/Off "hold" times, the low-pass filter adds latency to input recognition, since the software won't recognize a physical button press until the low-pass filter time elapses. This value should therefore be kept as small as possible. The default is 0, which doesn't apply any low-pass filtering at all. For many switches, the latency-free debounceTimeOn/Off settings are all you need to eliminate switch bounce artifacts, but some switches have enough intrinsic noise that low-pass filtering is also required.

Sets the debouncing low-pass filter time for rising edges, in microseconds. This is the minimum amount of time that the GPIO port must remain in the HIGH state after a "rising edge" - a LOW-to-HIGH voltage transition on the GPIO port - before Pinscape will recognize the new HIGH state. This is designed to filter out random electrical noise on the input, by requiring that the new HIGH level remain in effect continuously for a minimum amount of time before it's treated as legitimate.

The RISE time applies to physical LOW-to-HIGH voltage transitions on the port, regardless of the active-high/low setting on the port.

Unlike the debounceTimeOn/Off "hold" times, the low-pass filter adds latency to input recognition, since the software won't recognize a physical button press until the low-pass filter time elapses. This value should therefore be kept as small as possible. The default is 0, which doesn't apply any low-pass filtering at all. For many switches, the latency-free debounceTimeOn/Off settings are all you need to eliminate switch bounce artifacts, but some switches have enough intrinsic noise that low-pass filtering is also required.

If true, the GPIO port will be configured with an internal pull-up or pull-down resistor, as appropriate for the active="high" or "low" setting for the button. True by default. A pull resistor is generally required for ordinary buttons and switches, but you should disable the internal one if you provide your own external pull resistor, or if you're attaching some kind of device that drives the line high and low on its own. Some types of powered coin acceptor mechanisms actively drive the line high and low, for example.

This sets up a virtual button that's triggered by an accelerometer event. You can set the force and direction required to trigger the button.

Sets the source axis for the event: "x", "y", or "z".

Sets the direction of the nudge on the selected axis: "+" for the positive direction only, "-" for the negative direction, "+-" for either direction.

The amount of time to pulse the imaginary button, in milliseconds (1000 milliseconds equals one second). When the nudge axis reading goes over the threshold, the button reads as pressed for this interval.

The reset time for the nudge event, in milliseconds (1000 milliseconds equals one second). Each time the button is triggered, it performs its action, and then ignores the nudge input for this amount of time. This prevents the button from getting triggered repeatedly during a strong jolt to the cabinet.

The minimum reading on the nudge axis to trigger the event, 0 to 32767.

Sets the button to track the state of a logical output port (a DOF port). The button source acts like it's ON when the output port is within (or outside of) a specified value range. This lets you create buttons that are controlled by software on the PC, or by locally computed output ports.

Identifies the logical output port used as the source of the button's ON/OFF state. This is either a number giving the logical output port number, or a string giving the output port name. If this is a number, it gives the DOF port number, which is the same as the location in the config file outputs array, where port 1 is the first element in the array, 2 is the second element, etc. If this is a string, it's matched against the name properties of the output ports to identify the port.

Specifies the value range on the output port that triggers the button's ON state. By default, the range is {min: 1, max: 255, inside: true}, which means that the button is ON when the output port is at any non-zero value (since port levels are always in the range 0 to 255).

Sets the inside/outside test for the range. This is true by default, which means that the button is ON when the output port's value is within the range, i..e, min ≤ port_value ≤ max. If this is false, the button is ON when the output port's value is outside of the range - less than min or greater than max.

Sets the high end of the value range on the output port that triggers the button. The range is inclusive of the minimum and maximum, so a value is within the range if it's greater than or equal to min and less than or equal to max. By default, max is 255, which is the highest level value that an output port can be set to.

Sets the low end of the value range on the output port that triggers the button. The range is inclusive of the minimum and maximum, so a value is within the range if it's greater than or equal to min and less than or equal to max. By default, min is 1.

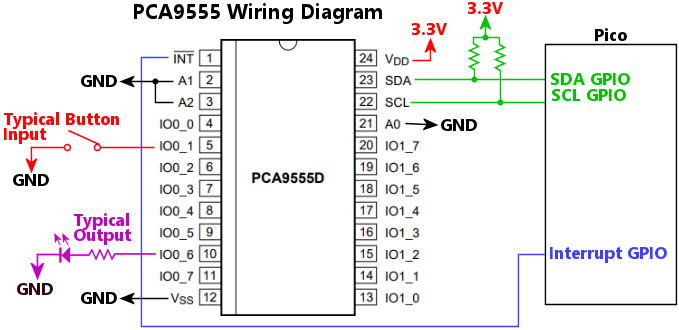

Connects the button to an input port on a PCA9555 chip. The PCA9555 is a GPIO expander chip that adds 16 digital (on/off) ports that can be used much like the Pico's own GPIO ports, including as button inputs. You can attach several of these chips to the Pico to add a large number of button parts.

The PCA9555 chip number, as an index in the "pca9555:" array in the JSON configuration file. The first chip listed in the array is number 0, the second chip is number 1, etc.

Sets the debouncing time for the switch input, in microseconds. Most physical switches "bounce" when switching between ON and OFF states, which means that the voltage level on the switch oscillates very rapidly for a brief time after the moment of contact. The brief instability in the signal can cause odd behavior in some host software reading the switch state; for example, if a button is mapped to keyboard input, the bounce effect might cause the key input to be repeated several times for a single button press. Debouncing refers to any sort of filtering that suppresses the oscillations after an on/off transition. Pinscape Pico debounces inputs by ignoring any further on/off changes for a brief time after each valid on/off change. This parameter sets the duration of that suppression time. The default value is 1000 microseconds (1 millisecond), which is long enough to suppress bounce in typical microswitches. If you experience any spurious input from a button, especially repeated inputs for a single button press, you can try increasing this. Longer values have the disadvantage that they limit the rate at which intentional fast taps can be processed.

The name of the port on the PCA9555 chip, as a string giving the pin label as in the data sheet. The input pins are arranged in two banks, "0" and "1", each with ports 0 to 7. The NXP data sheet uses the notation "IO1_5" (that's the letter I and the letter O, then bank number 1, underscore, port number 5). The TI data sheet reduces this to just "15" for Bank 1, Port 5. You can use either notation in the JSON file.

Sets up the logical button to trigger its action when the plunger position is inside or outside of a specified range.

Set this to true to trigger the button whenever a firing event on the plunger is detected. A firing event occurs when the user pulls back the plunger and releases it, or, equivalently, just moves it forward fast enough to mimic the same motion. If this is true and a range is also specified, the button will trigger on either condition - that is, on a firing event OR whenever the position is inside/outside the range.

Sets the "on" time after a firing event occurs, in milliseconds (1000 milliseconds equals one second). The button reads as pressed for this long after a firing event. When the button action is mapped to a keyboard key press or gamepad button press, it's usually necessary to hold the button press for a brief time, on the order of 10 to 20 milliseconds, to ensure that the PC detects the event.

Sets the plunger range that triggers the button.

Set this to true (which is also the default if you don't specify it) to trigger the button when the plunger position is inside the min-max range - that is, when the position is greater than the minimum and less than the maximum. Set it to false to trigger when the position is outside of the min-max range.

The high end of the trigger range, -32768 to +32767.

The low end of the trigger range, -32768 to +32767.

Sets up the logical button to trigger whenever a ZB Launch event occurs. A ZB Launch event occurs whenever a "firing" event occurs (that is, the user pulls back the plunger and releases it), or when the user presses the plunger forward onto the barrel spring as though pressing a button.

If this is set to true, which is the default, the button only triggers when ZB Launch Mode is in effect, as set through the DOF port assigned as the ZB Launch indicator. Set this to false to trigger the button on a ZB Launch gesture even when the mode isn't in effect.

The logical button type, which determines how On/Off state changes on the underlying physical button input are interpreted for the logical button. The default is "push", which is an ordinary momentary pushbutton.

| Type name | Description |

|---|---|

| "push" | This is the default; an ordinary momentary pushbutton. The logical action is activated for as long as the underlying physical button is pressed. |

| "hold" | The action doesn't take effect until the underlying button has been held down for a specified minimum interval; after that, it acts like an ordinary pushbutton, with the action activated until the button is released |

| "pulse" | When the underlying physical button is pressed, the action is activated briefly, for the "on" pulse time; then nothing happens until the button is released, at which point the action is pulsed again, for the "off" time period |

| "toggle" | Each time the underlying physical button is pressed, the action is toggled between ON and OFF |

| "shift" | This button acts as a modifier for other buttons, by turn its "shift bits" on as long as it's being pressed |