21. Cabinet Body

On the forums, virtual pinball machines are always called "pin cabs".

It's appropriate that the cabinet is the defining feature of these projects,

since it's what sets them apart from video pinball on an ordinary PC.

This chapter is about the literal cabinet part of

that - building the physical housing of the machine.

The bulk of this section consists of detailed plans for building a

replica of a 1990s-era Williams pinball cabinet, with some slight

changes to accommodate video pinball instead of a mechanical

playfield. With some tweaks, you can use the plans here to build a

replacement cabinet for an actual WPC-era pinball machine. The plans

are complete enough to build the whole thing from scratch, starting

with a couple of sheets of plywood.

Before we get to the building plans, we'll discuss the reasons behind

the design of the cabinet (both the original pinball machine design

and our "virtual" modifications), and some important things you should

consider before finalizing your own design. Every pin cab project is

unique, and I think most people will want to make at least some

customizations to the generic plans I provide.

This section has a lot of background information and digressions on

small (sometimes trivial) details, so it's rather lengthy. When

you're ready to go out to your workshop and get building, you might

prefer a more concise step-by-step list of dimensions and tasks. I've

tried to provide something along those lines in a couple of

appendices:

Design goals

The goal for most of us is to replicate the exterior appearance of a

real pinball machine. That's what I set out to do with my own virtual

cab, and I'm assuming in this section that it's your goal as well.

This chapter is therefore mostly a guide to building a replica of a

Williams pinball machine cabinet from the 1990s, using the same

materials and parts. The plan here isn't an exact replica,

because some modest changes are needed to make the virtual-pinball

elements fit better, but most of the differences are small. For the

most part, you could use the plans here to build a replacement cabinet

for a real machine (and just in case you actually want to do that,

I've tried to point out where and how my plans diverge from the WPC

design).

Even though the WPC design is more than 30 years old now, it's still

more or less the most "modern" pinball cabinet design, since most new

pinball titles today are built with essentially the same cabinet plan

and trim hardware as in the 1990s. Pinball is a much smaller industry

today than it was then, and I don't think the manufacturers have the

scale these days to do as much custom designing and machining, so they

keep re-using a lot of the time-tested parts and designs from the 90s.

Plus, the WPC cabinet design simply got most things right; there's not

much practical reason to change it. So newer machines look very much

like machines from the 1990s, as far as the basic cabinet shell goes.

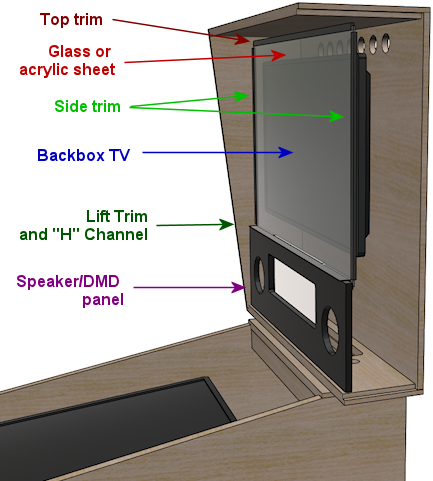

The only major change on the outside is the audio/video panel in the

backbox, which on newer machines usually features a video screen in

place of a dot matrix display, but that's not really a change to the

cabinet; it's just something that drops in to the standard cabinet

layout. You can build the basic WPC cabinet plan and take your pick

of speaker/display panel styles.

When I was building my own virtual machine, I discovered that the

design of the 1990s pinball cabinets is something of a secret art.

It's not secret due to any conspiracy of silence; it's just that

there's a lot of knowledge and experience that went into the design

that no one bothered to write down anywhere. Not anywhere public,

anyway; I imagine that there are still a lot of old engineering

diagrams and blueprints gathering dust in a basement file cabinet

somewhere, but those documents aren't available to hobbyists.

Owners of the real machines can learn a lot of the design details of

the original cabinets through observation, but if you don't have a

real machine to take apart and examine, you pretty much have to guess.

I'm fortunate to have some real machines at home, and that turned out

to be a huge help for building a virtual cab. Whenever I was unclear

on something, I could look at a couple of actual examples to see how

they did it, and see some of the variations in different model years. I

took advantage of that many times. So my goal in this section is to

pass along as much of that otherwise undocumented knowledge as I can,

in this one place, in an order that essentially provides a recipe for

building one of these cabinets.

I know that not everyone wants their cab to look exactly like a modern

commercial pinball machine. You might be basing your project on the

classic Gottlieb wedge-head machines of the 1970s, for example, or you

might want to create something completely novel. Even if you're

aiming for a different look, though, you might find it helpful to

understand how the 1990s WPC cabinet design works. Those cabinets are

the result of decades of refinement. Pin cabs have to solve a number

of geometry and functional constraints, and you'll face many of the

same issues in creating a wholly new cabinet design. It can be

helpful to see what the pros came up with after many iterations.

Build, buy, or convert?

There are three main options for creating the body of your cabinet:

- Build it yourself from scratch

- Buy a new empty pinball cabinet, pre-built or as a kit

- Convert an old real pinball machine into a virtual cabinet

If you're new to virtual pinball, the approach that might seem most

appealing at first glance is to convert an old real machine. Indeed,

some of the earliest virtual cabs were built as conversions from

machines that would otherwise have been scrapped, and it was a popular

approach in the early years. It has the advantage that it starts off

from the very beginning looking exactly like a real pinball machine,

and it saves you the trouble of coming up with your own cabinet

design and sourcing parts.

The conversion approach has become a lot less appealing lately because

of increasing prices. Almost every pinball machine is a collector's

item these days; old machines command surprisingly high prices even

when they're beat up, since there are plenty of people looking for

restoration projects. If you're lucky enough to find a donor machine

that no one wants to restore, it'll probably be in such bad cosmetic

condition that it might actually be cheaper and easier to start from

scratch. (You should also be prepared for some negative comments on

the forums, since there's a preservationist sentiment even among the

virtual pinball crowd. Many people see pinballs from past decades as

works of historical significance that can't be fully or genuinely

re-created once lost.)

Happily, the "build" and "buy new" alternatives are both quite

practical, and I consider both of them superior to conversion, even

without the price considerations. You can buy high-quality

reproduction cabinets that look exactly like the real thing, in kit

form or fully assembled. Or, if you have some basic woodworking

skills, you can build an excellent reproduction cabinet yourself. The

real machines use fairly simple designs that you don't have to be a

master carpenter to reproduce. This section provides ready-made

plans, so there's no research required.

What's more, it's easy to obtain all of the genuine cabinet hardware

(metal rails, legs, etc) needed to fit out a custom-built cabinet and

make it look exactly like a real machine. All of the hardware is

standardized across machines, and several big online pinball suppliers

sell the parts. You can thank the collectors for that - they buy

these parts to repair and restore their machines, so there's a

healthy market in the parts that keeps them readily available.

Here are my recommendations:

- For most people, I recommend using a VirtuaPin flat-pack kit. I

used this approach myself, and I'm very happy with the results. It's

not the cheapest option, but it's reasonably priced, and it yields an

excellent finished product. It's about the same level of difficulty

as assembling an Ikea product. With a little care, the result will be

essentially indistinguishable from a brand new commercial pinball machine

cabinet.

- If you enjoy woodworking and have a decently equipped workshop,

consider a scratch build. Doing it yourself is much cheaper than

buying a VirtuaPin flat pack, assuming you already have the tools, and

you should be able to get equally professional results with a little

care. Pinball cabinets are relatively simple as woodworking projects

go; they're built out of ordinary plywood, and they're all straight

lines and (mostly) easy joinery. But it does require some tools

beyond the home-handyman basics, and it's a fair amount of work, so

don't choose this option just because of the potential cost savings -

choose it because you enjoy this sort of construction project.

- If you don't want to do any woodworking, and you don't even want to

assemble a kit, you can order a fully built cabinet from VirtuaPin or

from a number of other vendors. VirtuaPin's pre-assembled product is

the best one I've seen, and it's the only one I know of that

faithfully reproduces the design of the real pinball machines. (It's

good enough that some collectors restoring real machines buy this kit

to use as their replacement cabinets.) The products I've seen from

other vendors use idiosyncratic designs and non-standard trim

hardware, so they don't look quite like the real thing. If a

realistic appearance is important to you, take a close look before

buying to make sure you like the design.

- I generally don't recommend trying to re-purpose an old real pinball

as a virtual cab, in part because old cabinets tend to be so beat up

that restoration would be more labor-intensive than building a new one,

and in part because the economics rarely pan out.

More on that below.

Economics of new vs used

If you're set on the idea of re-purposing a used cabinet, I'd suggest

doing a little research first to make sure you don't overpay. The

question you want to ask is: would I actually save money buying the

used cab, or would it be cheaper to buy the same parts new?

To answer this, ask the seller for a list of all the hardware parts

that the used cabinet includes - the legs, side rails, lockbar, etc.

Don't assume that everything is included, because a lot of eBay

sellers strip all of the parts out and sell them separately; a used

cabinet might not come with anything beyond the wood box. And only

consider the hardware that you'll actually use on your virtual cab,

since those are the only parts you'd have to buy if you were starting

from scratch. Only count parts that you actually need in the virtual

cab (e.g., don't count the playfield, bumper caps, etc), and only

count used parts if they're in usable condition.

To help you get started here's a list of the main parts that real

machines and virtual cabs have in common. See

Cabinet Parts List

for a more detailed parts list with descriptions. We left the price

column blank, since prices obviously vary over time and from one

vendor to the next, so you'll have to fill that in by checking current

prices at your preferred vendor(s) (such as

VirtuaPin,

PinballLife, or

Marco Specialities). For

the "wood body" line item, you can use VirtuaPin's flat pack or

unfinished cab body offerings for comparison. Remember, only include

the parts that the seller is including with the new cab, since you

want to compare new-vs-used for what you're actually getting from the

seller.

Add up the prices of the new parts, and compare the result to the

seller's asking price for the used cab. If the asking price for the

used cab is cheaper than the new parts, and everything's in good

enough shape that you can actually use it, you've found a good bargain.

If the seller is asking more for a beat-up used cab than what you'd

pay new, I'd pass on the deal.

| ☑ | Description | Price New |

|---|

| ☐ | Main cabinet wood body | $ |

| ☐ | Backbox wood body | $ |

| ☐ | Legs (qty 4) | $ |

| ☐ | Leg levelers ("feet") (qty 4) | $ |

| ☐ | Leg brackets (qty 4) | $ |

| ☐ | #8 x 5/8" wood screws for leg brackets (Williams ref 4108-01219-11, 4608-01081-11), or #10 screws if preferred (qty 32) | $ |

| ☐ | Leg bolts (⅜"-16 x 2¾" or 2½") (qty 8) | $ |

| ☐ | Side rails (qty 2) | $ |

| ☐ | Lockbar | $ |

| ☐ | Lockbar receiver | $ |

| ☐ | Coin door | $ |

| ☐ | Coin acceptors ("coin mechs") | $ |

| ☐ | Cashbox tray (Williams ref 03-7626) | $ |

| ☐ | Cashbox lid (Williams ref 01-10020) | $ |

| ☐ | Cashbox nest bracket (Williams ref 01-6389-01) | $ |

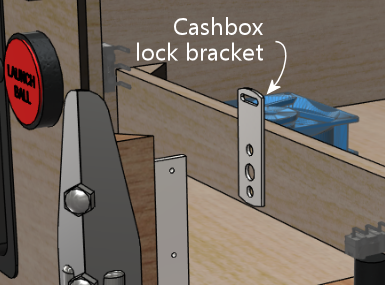

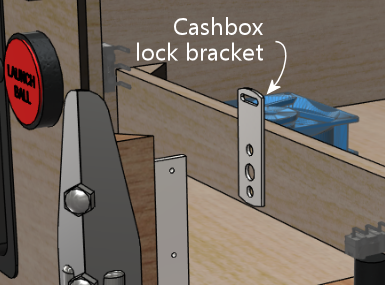

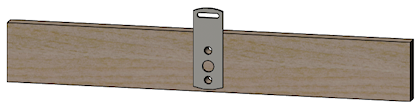

| ☐ | Cashbox lock bracket (Williams ref 01-10030) | $ |

| ☐ | Carriage bolts, black, ¼"-20 x 1¼" (qty 6: 4 for coin door + 2 for lockbar) | $ |

| ☐ | Flange locknuts, ¼"-20 (qty 6: 4 for coin door + 2 for lockbar) | $ |

| ☐ | Top glass | $ |

| ☐ | Rear plastic channel for glass | $ |

| ☐ | Side rail plastic channels for glass (qty 2) | $ |

| ☐ | Plunger (ball shooter) assembly | $ |

| ☐ | Ball shooter mounting plate (Wiliams ref 01-3535) | $ |

| ☐ | #10-32 x ¾" bolts for mounting plunger assembly (qty 3) | $ |

| ☐ | Backbox hinges (qty 2) | $ |

| ☐ | Backbox hinge backing plates (qty 2) | $ |

| ☐ | Carriage bolts, ¼"-20 x 1¼" (qty 6, for backbox hinges) | $ |

| ☐ | Flange locknuts, ¼"-20 (qty 6, for backbox hinges) | $ |

| ☐ | Pivot bushing carriage bolts (qty 2) | $ |

| ☐ | Hex pivot bushings (qty 2) | $ |

| ☐ | Backbox latch | $ |

| ☐ | Backbox latch bracket | $ |

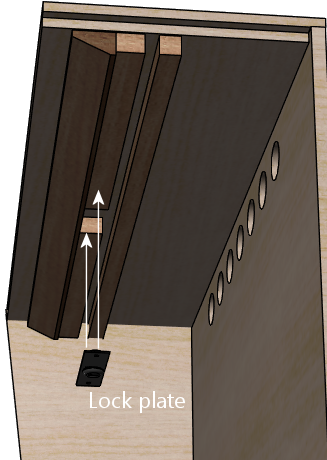

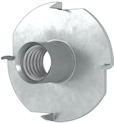

| ☐ | Backbox lock plate assembly | $ |

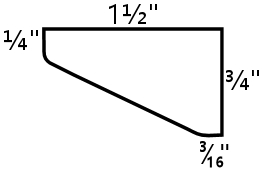

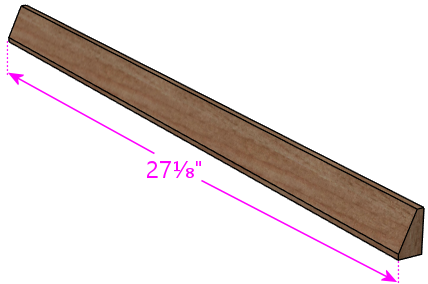

| ☐ | U-channel, metal, ⅝" x ⅝" x 27⅛" (backbox speaker panel holder) | $ |

Where to find used machines

Your best bet for finding a used machine at a good price will be local

sellers. Search your local craigslist and local newspaper classified

ads. A particularly good place to find a deal is at an estate sale.

Heirs often want to clear out the house quickly and won't have any

sentimental attachment to an old pinball.

If you can't find anything locally, eBay will give you access to

sellers nationally (and even internationally). But I wouldn't get my

hopes up; it's hard to find a good deal on a used cab on eBay these

days. For one thing, shipping a cabinet is expensive due to the size

and weight; shipping can add about $400 to the price. For another,

eBay sellers know they can get top dollar for used cabs, so the base

price is unlikely to be a bargain. Most eBay sellers are also savvy

enough to strip a machine of all of the parts and sell them off

separately, which largely defeats the purpose of reusing an old

machine.

Kits and pre-built cabinets

If you can't find or don't want to use a salvage machine, but you also

don't want to build everything from scratch, there are several

companies that will sell you a brand new cabinet. For options, search

the web for "new pinball cabinet" or "pinball cabinet restoration".

One vendor I can recommend from personal experience is

VirtuaPin. They sell cabinets in both kit

form and fully assembled, and can customize them to your specifications.

You should be able to find options ranging from "flat pack" kits that

you assemble yourself, to fully assembled cabinets with all of the

hardware and artwork installed.

The cheapest and most DIY option is a flat pack kit. This is like an

Ikea bookshelf: it consists of the wood parts, pre-cut and

pre-drilled, ready for you to assemble. This is the cheapest kit

option, since you provide the assembly labor, and because shipping is

cheaper than for a bulky assembled cab. The degree of difficulty is

slightly higher than for assembling Ikea furniture, but only slightly;

no real woodworking skills are required, and you'll just need basic

tools like screwdrivers and hammers. You might also have to do some

sanding to even out corners and edges. And you'll have to do your own

finish work (painting, staining, or applying decals). I used the

VirtuaPin flat-pack kit for my own cabinet, and I highly recommend it.

They use a good furniture-grade plywood, and the design is a faithful

reproduction of the WPC cabinets that Williams shipped in the 1990s,

so the result is exactly like a brand new real machine.

The next step up in price and completeness is an assembled cabinet

shell. This is just the wood shell, typically unfinished (ready for

you to paint, stain, or apply decals), and without any of the cabinet

hardware accessories installed. This eliminates the assembly work

required for a flat pack. It's considerably more expensive to ship

because it's so bulky.

At the high end price-wise, you can buy a fully assembled cabinet with

all of the hardware and graphics pre-installed. VirtuaPin sells these

in addition to their flat-pack and assembled-but-unfinished products.

All of the VirtuaPin options use the same materials and design as

their flat pack, so they all yield excellent reproductions of the

1990s Williams machines. There are other vendors selling pre-built

cabinets as well, but check their designs carefully before buying,

because I've seen a couple of other vendors who use their own ad hoc

designs that look a bit cheap and cheesy to my eye.

Tip: Ask about the

button hole layout.

Tip: Ask about the

button hole layout. If you order a kit or pre-built cabinet, ask

the seller for details on the locations of button holes they

pre-drill, and ask them to customize the drilling to your plans if you

have something else in mind. The vendor might drill holes by default

that you don't want. Pay particular attention to the placement of the

plunger and flipper button holes. Many virtual cab builders choose

non-standard locations for these to accommodate the playfield TV (see

"The dreaded plunger space conflict" in

Playfield TV Mounting

and "Positioning the plunger" in

Plunger).

If you're

not sure how you want to handle this at the time of your order, you

can simply ask the vendor not to drill any holes for the plunger or

other controls. That will give you the flexibility to drill them

yourself later when you know how everything will fit together.

Scratch build

A scratch build is the cheapest option if you already have most

of the tools required. The raw materials consist mostly of a couple

of sheets of plywood. If you don't already have the tools, it's probably

cheaper to buy a pre-built cabinet, but not by a huge margin

- you don't need a huge set of tools. A scratch build also lets

you build exactly what you want.

Lumber:

- 3/4" (nominal) plywood, two 4'x8' sheets, for almost all of the main cabinet and

backbox. Choose a quality hardwood plywood that's graded for furniture or

cabinetry use. Commercial pin cabs are typically birch.

The ¾" thickness is important, as many of the

trim parts and controls (like flipper buttons and plunger) are

designed to fit into ¾" walls.

MDO plywood is even nicer, if you can find it. MDO is a

hybrid product with a plywood core and an MDF veneer, so it has

the strength and lightness of plywood and the flat, grainless

surface finish of MDF. The MDF veneer saves hours of prep work

for painting and decals.

It's just barely possible to fit a standard-width cab into a single 4' x 8' sheet,

but it's much easier with two sheets. See Plywood Cutting Plans for Cabinet Construction

for layout suggestions.

- 1/2" (nominal) plywood or particle board, one 4'x8' sheet, for the

cabinet floor and the back wall of the backbox. Most commercial

machines use particle board, to cut costs, since these pieces aren't cosmetic.

Plywood is a nice upgrade if your budget permits. It's stronger

and lighter.

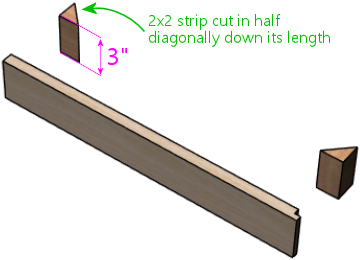

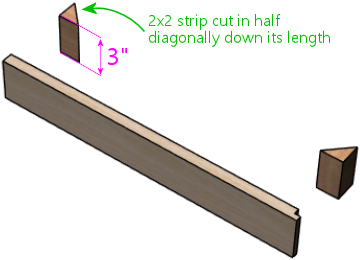

- A length of 2x2 (nominal) board, for corner braces. A nominal 2x2

is actually 1.5" on a side. It usually comes in 8-foot lengths. You

need at least 5 feet, so one 8-foot board will leave you with some

spare material for test cuts and do-overs.

- A length of 1x2 (nominal) board, for a trim piece for the backbox.

You can also fashion this out of the same 2x2 as the leg braces, but

it's easier with a 1x2. This board needs to be at least 28" long.

"Nominal" lumber dimensions refer to what the lumber yard calls it,

not the true size. Plywood is generally 1/32" thinner than the

nominal thickness, and dimensional lumber, such as 1x2 or 2x2 strips,

is generally 1/4" to 1/2" less in each dimension than the nominal

size. So when the list above calls for 3/4" plywood, it means you

should buy what the lumber yard calls 3/4" plywood, even though the

true thickness will be slightly less than that.

Some cab builders use MDF (fiberboard) instead of plywood for the

whole build. I prefer plywood, but MDF works too. Each material has

some advantages over the other. MDF is cheaper, and it's nearly

perfectly uniform in thickness and composition. MDF sheets also tend

to be perfectly flat, whereas plywood often has some warping, even

fresh from the factory. The downsides of MDF are that it's heavier,

it's not as sturdy or as durable as plywood, it doesn't hold screws as

well, and it can sag over time.

Most commercial cabinets use a mix of plywood and particle board:

plywood for the cab and backbox walls, and particle board for the

cabinet floor and the back of the backbox. I'm normally in favor of

faithfully replicating the original details, but in this case I see no

benefit, since the particle board in the originals was purely for cost

reduction and not for any functional reason. It's a worthwhile

upgrade to use plywood for everything.

I personally prefer to use real pinball parts wherever possible,

instead of trying to improvise something out of common hardware parts.

It can be a bit more expensive to use the real parts, but they tend to

look better, and in many cases they're easier to work with because

they're purpose-built for a specialized job. An exception is that

many of the fasteners and generic nuts and bolts that you can buy

anywhere. But even some of the generic-sounding hardware can be hard

to find outside of pinball vendors. Anything that I listed with a

Williams part number in the master list (

Cabinet Parts List) is

probably hard to find outside of pinball suppliers.

Tools: See

Cabinet Building Tools for recommendations on the woodworking

tools you'll need for building the cabinet.

Choosing a cabinet design

As far as I'm concerned, there's only one cabinet design that we need

to concern ourselves with: the WPC cabinet. This is the cabinet that

Williams (and its co-brands Bally and Midway) used for nearly all of

their machines made during the 1990s, which were based on the

electronics platform known as WPC, for Williams Pinball Controller.

Thus the name "WPC cab". I don't know if Williams ever had an

official internal name for this series of cabinets, but probably

not; I don't think they thought of it like that. My guess is that they

treated each game's cabinet as unique, as suggested by the unique part

number assigned to each game's cab. So "WPC cabinet" is a made-up

term of convenience, not an official name - and it's also not quite

precise, in that the last dozen or so System 11 titles also used the

same design. The wood shop apparently didn't coordinate their

updates in lock-step with the electronics department. But even so,

"WPC cab" is a pretty good name for our purposes, and other pinball

people will probably know what you're talking about if you refer to

it.

One good reason to use the WPC cabinet design is that it's by far the

easiest to find parts for. Machines from this generation are still

widely deployed, and they share a lot of the same parts (Williams

quite intentionally re-used parts across titles to keep their own

costs down), so there's plenty of demand for most of the common

cabinet parts even today. If you design to the WPC specs, you'll be

able to take advantage of that, since your machine will be compatible

with the same readily-available parts. Using real pinball parts gives

your machine an authentic look, and it's a lot easier than engineering

and fabricating your own custom metal parts.

Another reason to use the WPC cabinet plan is that it still looks

up-to-date, because most newer commercial machines are still using the

same exterior design. Stern's latest machines still look almost

identical, as do the machines from the boutique pinball makers like

Jersey Jack and Spooky Pinball. This cabinet style is what you'll see

almost every time you encounter a recent pinball title in an arcade or

bar. A virtual cab following the same plan will look exactly like

what everyone expects a real pinball machine to look like.

For a DIY project, you're always free to come up with something

completely different, either to fit your particular needs or purely to

be unique. If you have other ideas for how your cabinet should look,

you can take as much or as little from the WPC design as suits you.

We provide detailed plans for the WPC design later in this

section. Before we get to the plans, though, there are some

variations that you might want to consider, so that you can customize

the plans for your project's specific goals.

Standard and Widebody cabinets

The WPC design is what we usually call the "standard" cabinet, because

Williams/Bally/Midway used this for most of the machines

they shipped in the 1990s. However, they also used a variation of the

plan with a slightly wider main cabinet, to accommodate a larger

playfield. This wider variation was used for seven titles in all:

The Twilight Zone (1993), Indiana Jones: The Pinball

Adventure (1993), Judge Dredd (1993), Star Trek: The

Next Generation (1993), Popeye Saves the Earth (1994),

Demolition Man (1994), and Red & Ted's Road Show

(1994). The official marketing name for these games was "Superpin",

but no one ever uses that term; everyone in the virtual pinball world

calls these the "widebody" machines.

The widebody design is identical to the standard WPC cabinet in almost

every detail, except that the main cabinet is 2¾ inches wider

than the standard body. All of the other dimensions are exactly the

same as in the standard body.

A lot of people assume that the widebody WPC cabinet design had a

corresponding "widebody backbox", but not so.

Williams used the same backbox dimensions for their standard

and widebody machines. In fact, my guess is that they chose the

widebody width they did precisely because it's as wide

as you can go without making the backbox wider.

That doesn't mean that you can't customize the backbox size if you're

using a widebody design, just that you don't necessarily have to. If

you're going wider than wide, though - if your main cabinet outer

width goes over about 25" - then you will have to widen the backbox,

assuming you plan to use the WPC-style hinges. The backbox has to be

at least 3.5" wider than the cabinet for the WPC-style hinges to

work.

Widebody machines require a wider lockbar and cover glass. Pinball

vendors sell widebody versions of both that fit the Superpin cabinet

dimensions, so you can still use off-the-shelf parts with this design.

The widebody lockbar fits the standard lockbar receiver (the hardware

piece that mounts in the cabinet to hold the lockbar in place), so you

don't need a special version of the receiver. All of the other

hardware is interchangeable with the standard body machines.

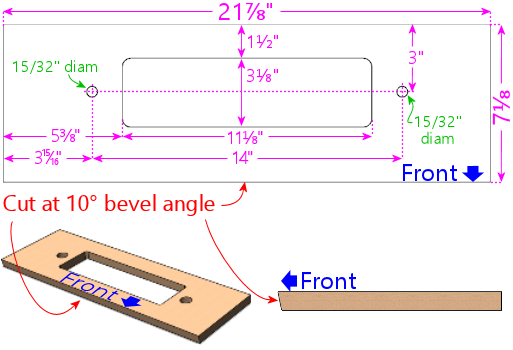

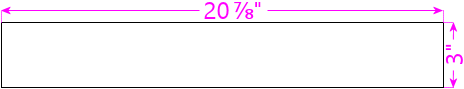

Note that my plans in this section peg the standard-body cabinet

exterior width at 21-7/8", which is what I read on the tape when I

carefully measure my own original Williams cabinets, whereas most

other Internet plans I've seen say it's 22". Maybe everyone else is

rounding up, or maybe my cabs have shrunk a little bit over the years

(they did all leave the factory more

than 30 years ago). It's a pretty trivial difference, but I thought

I'd mention it. The standard lockbar will fit in either case, but it

might be a little snug on a 22" wide cabinet.

Custom width

In addition to the WPC standard-body and Superpin widebody designs,

there's a third option: you can design a cabinet with a custom width

that doesn't match either of the Williams WPC-era designs.

The main reasons to build to a custom width are to get an exact fit for

your playfield TV, or to accommodate a TV that's even wider than what

will fit in a WPC widebody cabinet.

A custom width requires a custom lockbar and custom glass cover. As

long as you use the standard cabinet length, you can still use all of

the other off-the-shelf hardware.

To order a custom lockbar, contact

VirtuaPin. They're the only

current source I know of, so hopefully they'll keep selling them. Expect

to pay about double the price of the standard lockbar (which

I think is a pretty reasonable premium for a made-to-order metal

part that has to look nice).

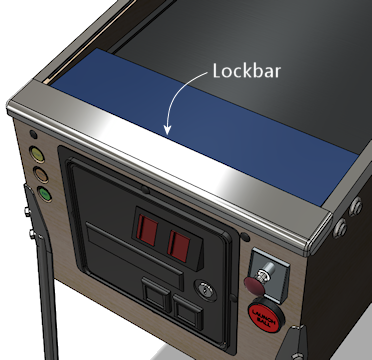

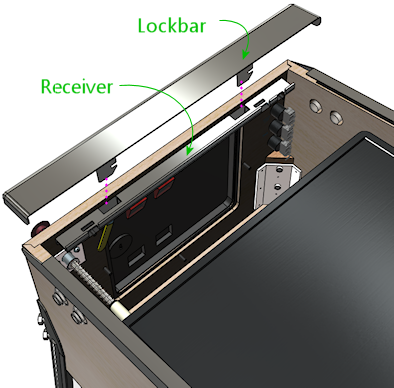

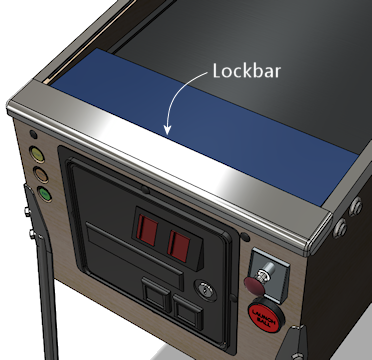

The lockbar is mated with a second part known as the

"lockbar receiver". The receiver does not need to be

customized for different widths; the standard receiver will work with

any lockbar width, as long as your cabinet is wide enough to accommodate it

(a minimum of 19½ inches inside width) . Keep the minimum

size in mind if you're designing a mini-cab that's narrower

than the standard-body cabinets.

Pinball vendors don't sell custom glass, but you should be able to

order it from a local window glass dealer. Any glass shop should be

able to fabricate a custom glass sheet for you in almost any desired

size. Once you know the inside width of your cabinet, order a

tempered glass sheet in the required width, by 43" length, by 3/16"

thickness.

When calculating the required width of your glass, take into account

the overhang beyond the inside dimensions. The easy rule of thumb is

to make the glass ½" wider than the inside width

of your cabinet (that is, the distance between the insides of the side

walls). For example, the standard body cabinet has an inside wall-to-wall

width of 20½ inches, so the standard playfield glass is 21" wide.

One more tip about ordering custom glass: ask the vendor to omit any

marking that identifies the glass as tempered. Glass shops sometimes

include a certification marking on tempered glass, in case you're planning

to use it for something like a shower enclosure where tempered glass

is legally required by building codes. You don't need any such

marking for legal purposes in a virtual cab, so you'll probably prefer

to avoid the visual clutter.

How to choose a cabinet width

If it weren't for the constraint of fitting a TV, I'd recommend the

standard-body plan and leave it at that. Using the standard

dimensions produces a machine with exactly the right proportions to

look authentic, and it lets you use readily available off-the-shelf

parts for all of the hardware. It's the easiest, most cost-effective

approach, and it looks good.

But sadly, TV manufacturers don't always cooperate with our virtual

pinball plans. TV manufacturers only make TVs in certain sizes, so

we're stuck with whatever sizes are on offer. The TV you pick based

on price and performance might not be available in exactly the

right size for a standard cabinet.

What size TVs will the standard cabinet sizes accommodate? There's no

absolute rule here, since the nominal diagonal size of a TV doesn't

tell you the exact exterior dimensions - the only way to be sure is to

measure the TV. You might also be able to find the dimensions listed

in the specs on the manufacturer's Web site or on a retailer site.

Generally speaking, a standard-body cab will accommodate most TVs up

to 39" diagonal, and you might be able to squeeze in some 40" models;

and a widebody should handle most TVs up to 45".

When I built my own cab, I chose standard-body dimensions, mostly

because I wanted my virtual cab to blend in with my small collection

of real standard-body pinballs. At the time, 39" TVs were readily

available, so you could easily find a TV to fit the standard-body

dimensions. As of 2022, though, 39" TVs are rare. The most common TV size

that's in range for a pin cab today is probably 42", and that requires

a widebody cabinet. So if I were building a new cab right now, I'd

probably have to go with a widebody design. In any case, I'd try to

use one of the original WPC sizes - standard or widebody - rather than

building to a custom size tailored to the TV, so that I could

use off-the-shelf cabinet hardware.

Custom length

As long as we're on the subject of custom widths, we should consider

lengths as well.

As with a custom width, the main reason to build to a custom length is

make a TV fit exactly. As discussed in

Selecting a Playfield TV, a

real pinball playfield is much more elongated than a 16:9 TV screen; a

typical 1990s era playfield is more like 20:9. So placing a 16:9 TV

in a standard-sized cabinet leaves a few inches of dead space at the

front and/or rear of the cabinet. Some cab builders don't like that

idea because they want to fill every square inch with TV display area.

One way to deal with the extra space is to remove it by shortening the

cabinet length to exactly fit the TV.

In my opinion, it's better to stick with the standard cabinet length

and accept that there will be some extra front-to-back space. The

main problem with a custom length is that you won't be able to find

side rails or glass guides; no one sells those in custom sizes as far

as I know, and they'd be difficult to fabricate yourself unless you

have some good metal-working tools. Besides, the extra space can

be put to good use for features that you might want anyway:

- If you're going to install a plunger, you might need 3-4" of extra

space between the front of the TV and the front of the cab to make

room for the plunger mechanism.

- Even if you don't need the space for a plunger, I still like setting

the TV back a few inches from the front for the sake of sight-lines,

so that you don't have to look straight down to see the flippers.

- Space at the front of the TV can be used for an "apron" similar to

that on a real machine, with printed instruction cards, or even small

monitors that display live instruction cards, scores, etc.

- Space at the back of the TV can be used for a flasher panel or

LED matrix.

Custom backbox sizes

As with the main cabinet dimensions, some virtual cab builders choose

to deviate from the standard backbox sizing to better fit a selected

TV.

Finding a backbox TV that fits the available space can be even more

vexing than finding a playfield TV. There are two big problems here.

The first is proportions: modern TVs all use the 16:9 aspect ratio,

but the translites in the WPC design are much squarer: approximately

13:9, closer to the old-fashioned NTSC 4:3 ratio. The second problem

is that there are very few models available that are even close to the

right size. The most popular current TV size that's close to what we

need is probably 32", but a 32" TV is too wide for a standard backbox.

The next size down tends to be 27" or 28". A 28" TV will leave about

an inch of dead space on each side, and a few inches above and below.

A 29" would be close to perfect, but that's never been a common size.

You can't control what sizes the TV manufacturers make available, so

you can either live with a little dead space around the perimeter, or

you can resize the backbox to fit the TV. I personally think the dead

space is the better compromise, in part because it lets you use

standard off-the-shelf pinball parts, but mostly because the backbox

shape will look "wrong" if you change it from the standard. This is a

case where I think a lot of cabinet builders tend to fixate on the

wrong thing during the planning stages, by focusing on the dead space

rather than the overall proportions. The thing that you might not

appreciate during the planning stage is that any dead space tends to

disappear into the background when you're actually playing. Your eye

sees what's there (the backglass graphics), not what's missing (the

dead space around the edges). The proportions of the overall outline,

on the other hand, are always noticeable.

If you do want to consider custom dimensions for the backbox, keep in

mind that some of the associated hardware parts are sized for the

standard dimensions, so you might not be able to use off-the-shelf

parts for everything. Here are the parts that will be affected

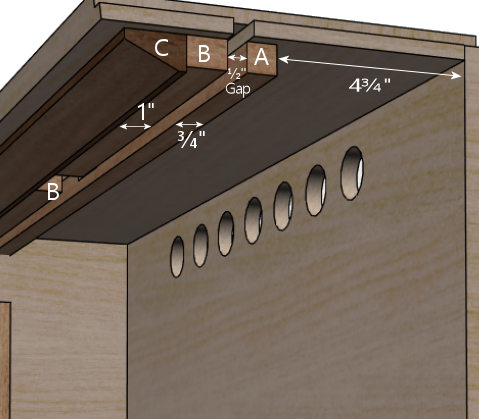

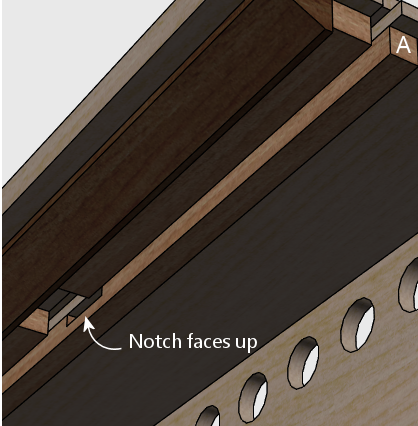

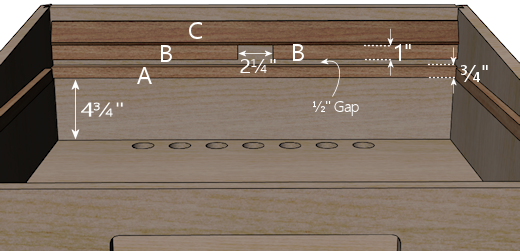

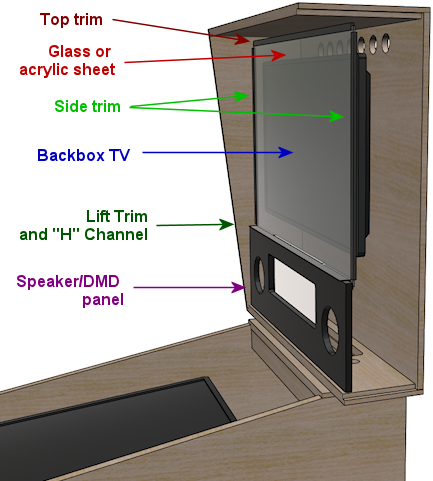

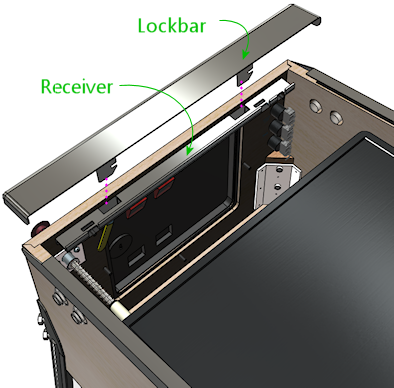

(see the illustration below if you're not familiar with all

of these):

- The glass or plexiglass cover for the TV. This isn't a required

part, but I recommend including it because it creates a more authentic

appearance. There's no downside to a custom size for this part,

because it doesn't come in an off-the-shelf version to begin with;

you'll have to custom-order it even if you're using the standard size.

You can have this made at any local window glass shop or plastics

store, and they'll be able to cut it to whatever size you need.

- Trim pieces for the glass/plexi cover. Real pinball machines use

black plastic trim around the edges of the translite. These are only

available in the standard sizes. You can fairly easily cut them to

smaller lengths if necessary, but there's no good way to make them

longer, so you'll have to live with some gaps if you use a wider

or taller than normal size.

- Speaker panel "H" channel and translite lift trim. These are plastic

trim pieces that go at the top of the speaker panel and bottom of the

translite, respectively, and they're sized to the standard width. If

you use a wider-than-normal width, you can use the standard pieces,

but there will be some gaps at the edges.

- Speaker panel. If you use a non-standard width, you'll need a

custom speaker panel, assuming you're using the three-monitor

configuration. No one sells those in custom sizes, so you'll have to

fabricate one yourself. The ready-made speaker panels are made from

plywood or particle board, so building your own only requires

woodworking tools. Be aware that it's a fairly advanced project

requiring precision work. You'll have to cut two large circular holes

the speakers and a large rectangular opening for DMD. I'd recommend

using a CNC machine (a computer-controlled cutting machine that cuts

according to a digital plan). There are online services for this,

such as SendCutSend.

If you live in or near a major city, you might also be able to find

a local CNC service, or a "maker" facility that lets you use their

equipment for an hourly fee.

Mini cabs

A popular variation on the basic cab design is to scale things down a

bit from the real machines. This can be especially attractive if you

don't have a lot of space, and might help gain acceptance from

skeptical spouses or housemates.

There's no "standard" mini-cab design, but you can find ideas from

other people's builds by searching the cab forums at sites like

vpforums. Many people who've built their

own cabs post build logs with details of their design.

If you want to design a mini-cab from scratch, you can start with the

basic WPC design, and just scale down all of the dimensions based on

the playfield monitor you choose. A 32" TV makes a good core to build

a mini-cab around; if you scale everything down proportionally, it

yields a cab that's about 3/4 of the full size. That's enough of a

reduction to fit more comfortably into a residential setting, but it's

still big enough to be free-standing.

A few people on the forum have shrunk things down even further, to

table-top or hand-held size, using a small computer monitor or tablet

as the playfield.

For a mini-cab in the 3/4 scale range, you should be able to build it

pretty much the same way that you'd build a full-size cabinet. You'll

have to make the same adjustments to cabinet hardware discussed above

under "custom width" and "custom length", but otherwise you should be

able to use standard materials (such as ¾" plywood for the

enclosure) and many of the standard hardware parts. One thing to keep

in mind is that interior space will be a bit tight for the

electronics, but you should be able to fit the necessary computer

parts and a basic set of feedback devices.

If you reduce the scale to table-top or hand-held dimensions, you'll

have to invent a lot more of the design on your own, since most of the

standard hardware will be too large. That's beyond the scope of this

guide, but you should be able to find one or two examples in the

forums or elsewhere on the Web if you're looking for inspiration.

Note also that all of the pinball software discussed in this guide is

for Windows PCs, so if you're considering something else (like a

tablet or Raspberry Pi) as the computer core, you'll also have to find

other software to use. There are some decent commercial pinball games

for tablets that could serve, but the commercial games don't tend to

have any integration with cabinet features, so it might be challenging

to make everything work the way you want it to.

WPC cabinet plans

We now present our WPC standard-body cabinet plans. These are based

primarily on measurements taken from actual WPC pinball machines, with

some additions and modifications to accommodate the peculiarities

of virtual pinball. I've tried to identify all of the

deviations from the real machines, for those with a special interest

in accurately re-creating the originals.

Other Internet plans

There are several other pinball cabinet plans available on the Web,

including other replica WPC designs. Some of the other WPC plans I've

seen have slight variations from mine, so you might want to compare

and contrast any others you find as a sanity check, and to see if

there's anything you prefer in the variations. I've taken a great

deal of care to check my plans against actual WPC machines, and I

believe the version presented here is the closest to the real thing

that I've seen, but of course that doesn't mean they're the ideal

plans for every build, just that they're close to what Williams

actually did build. You might have good reasons to deviate from that.

Most of the details can be changed in small ways without much

affecting the usability of the finished machine. (One detail that you

probably shouldn't tinker with is the placement of the

flipper buttons, since that's such a crucial part of the feel,

and it's highly consistent on the real machines.)

One set of plans I'll call out in particular is Jonas Kello's Sketchup

model, available on

github:

The nice thing about his 3D model is that you can look at it from all

angles, which might be helpful whenever my illustrations leave

something unclear about the spatial relationships between components.

Jonas's model appears to have been prepared with excellent attention

to detail. One warning, however: he explains that he took his

measurements from a widebody WPC machine (Star Trek: The Next

Generation) and adjusted them to infer the standard-body

dimensions. This creates an opportunity for errors and

inconsistencies to creep in, and I have in fact found a couple of

errors in his model that are likely due to this. My measurements were

taken directly from standard-body machines (Theatre of Magic

and Medieval Madness), so even though my figures undoubtedly

have inaccuracies of their own, they're at least free of that

particular source of error. In addition, even where our measurements

essentially agree, there are a number of slight differences, on the

order of 1/16" to 1/8", which I attribute to some combination of

measurement error and actual variations in the machines we sampled.

Another set of plans worth mentioning can be found in this Pinside

thread by Swinks, which has measurements from original WPC

standard-body machines (per the thread, mostly taken from Creature from the Black Lagoon,

with some corroboration against Bram Stoker's Dracula and Stern's

Iron Man):

Finally, Greg Butcher, a/k/a mameman, drew up a set of WPC widebody

plans many years ago that's often referenced in the virtual

cab forums. They have some inaccuracies in the details of the

construction, but they're still a useful reference. Jonas Kello

captured them in his github repository:

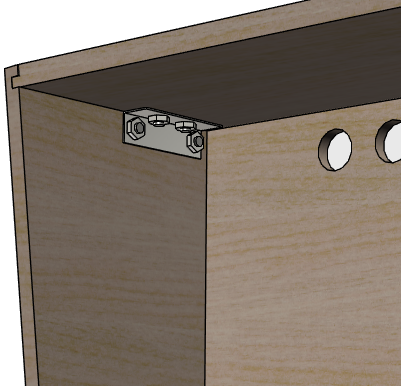

Joinery

In wood-working, joinery is the art of forming joints where pieces of

wood meet. There's a lot more to this than just nailing boards

together; joins can involve angled edges to hide seams, and

interlocking tabs and slots to add strength. Joinery is a huge

subject that goes well beyond my expertise, so I won't try to offer a

primer here. However, I do want to provide a quick overview of how

the corner joints are built in the real pinball machines, because

you might want to adapt these - either to something simpler or

to something better.

Apart from the corner joins, most of the joins we use in the plans are

straightforward enough that you probably won't need to change them.

Most of the joins (save the corners) are simple dado or rabbet joins

that you can execute with straight router bits or a table saw.

The only place in a pin cab where fancy joins are called for is at the

corners of the main cabinet. The front corners in particular are

prominently visible, so you'll want them to look nice, and they need

to be fairly strong, given how heavy a pin cab is. There are several

good ways to do these joins, and even the commercial manufacturers

haven't settled on a single best way - they've used a number of

approaches over the years. I'll go over the details for several good

options below.

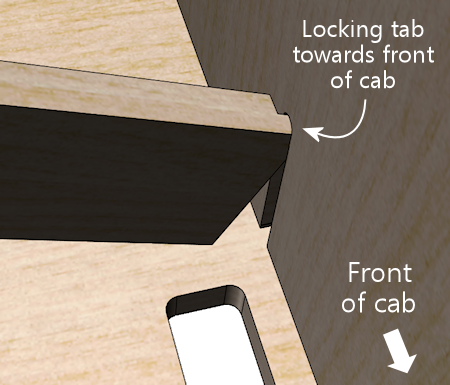

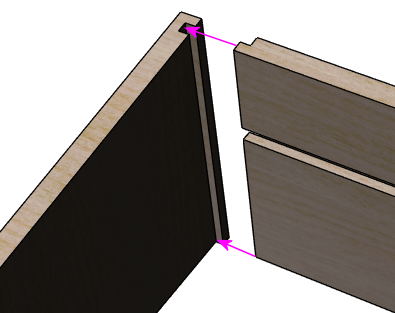

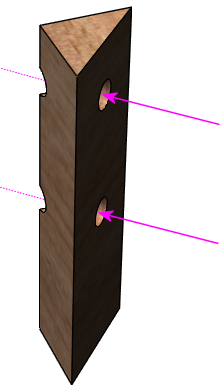

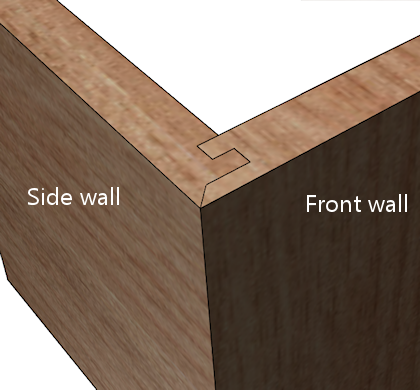

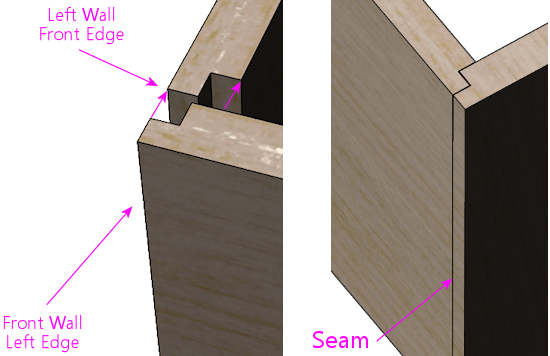

Locking miter: This is the corner join used on the WPC cabinets of

the 1990s. It's called a "locking miter" because the outside edges meet

at a 45° angle (that's the "miter"), and it has a sort of

jigsaw-puzzle pattern of interlocking tabs and slots that align

the pieces and hold them together (the "lock").

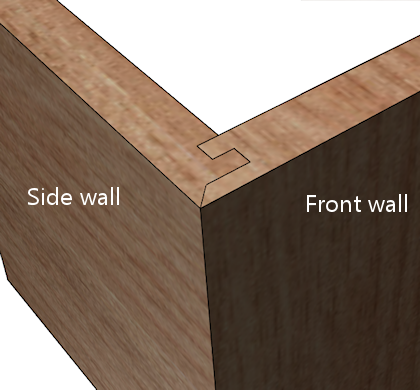

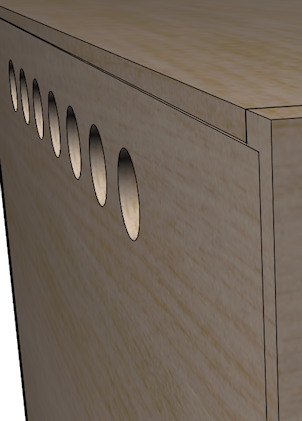

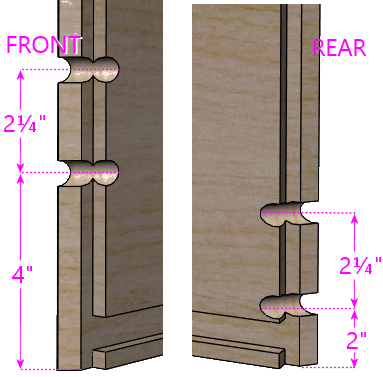

Locking miter join, shown at the front left corner of the main cabinet.

This is the type of join that Williams

used for the original WPC cabinets from the 1990s.

This is a really nice way to make your corners. The mitered corner

makes the seam invisible, and the join is very strong when glued

thanks to all of the surface area in the interlocking tabs. You

can see from the diagram that that shape is a little complicated

to cut, but it's surprisingly approachable, even if you don't

have a lot of woodworking experience. For a complete recipe,

using a table saw and router table, see

Lock Miter I: The Plywood-Friendly Way.

There's also an alternative approach that uses a special-purpose

router bit, explained in

Lock Miter II: The Special Router Bit Way. The first

approach works a lot better with plywood, so I think

it's the right one for a pin cab project.

Locking rabbet: This is essentially a simplified version

of the locking miter join that dispenses with the 45° bevel

at the corner.

This join was used on many commercial machines of the 1980s, including

many Williams System 11 machines. It has the same self-aligning and

self-squaring advantages as the locking miter join. It's a step down

aesthetically, since there's a seam along one side, but that

can be minimized by making the front tab fairly thin. The trade-off

is that a thinner tab is more delicate prior to assembly, so you have

to be careful handling the piece. This join is quite a lot easier to

execute than the locking miter; it only requires three cuts at each

corner.

I haven't written a recipe for this join, but it's easy to find Web

tutorials, since it's used a lot in mainstream cabinetry,

especially for drawers. Search for "locking rabbet join" or "locking

drawer join".

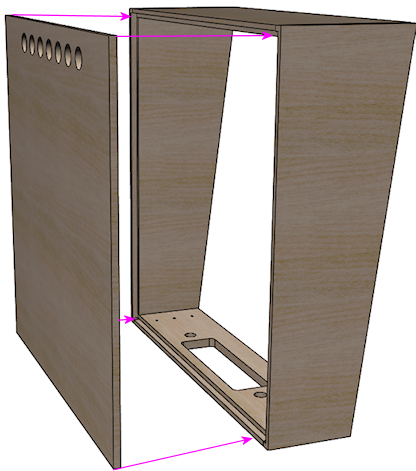

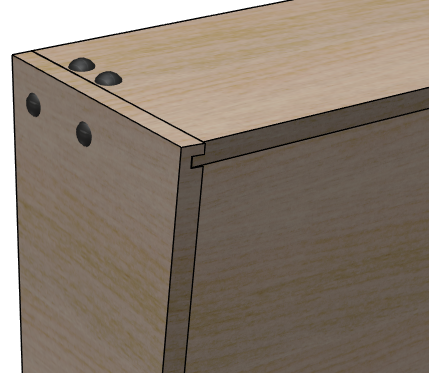

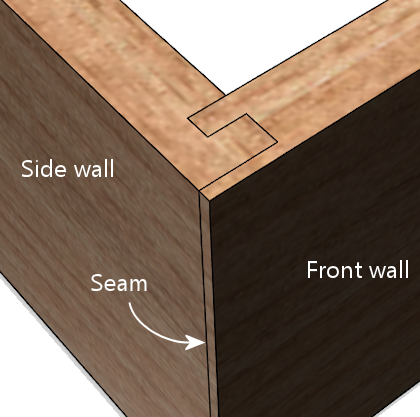

Mitered rabbet: This is join has a mitered corner like the

lock miter, but it dispenses with the interlocking tabs, and uses

a simpler "rabbet" pattern instead.

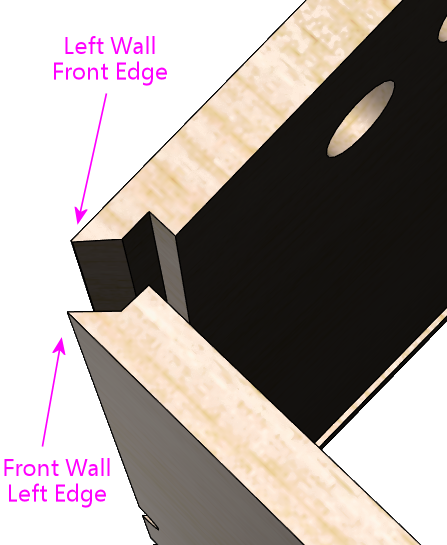

Mitered rabbet join, at the corner between the front wall and

left wall of the cabinet.

Top view of the front section, with a mitered rabbet at each

corner.

The mitered rabbet has the same aesthetic advantage as the lock miter,

in that it places the seam exactly at the corner. It's also fairly

strong when glued.

You can make a mitered rabbet using either a special router bit set or

just a table saw. I haven't attempted either myself, so I won't try

to provide instructions, but you can find tutorials on the Web.

Search for "mitered rabbet with table saw" or "mitered rabbet router

bit". The difficulty level seems similar to

that of the lock miter, but it doesn't require as many separate

steps, so it's at least a little less labor-intensive.

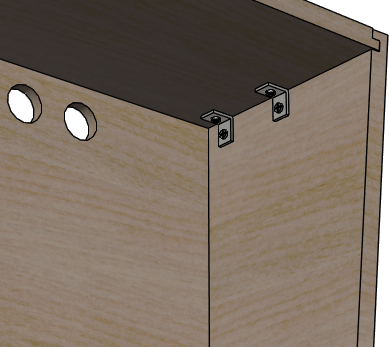

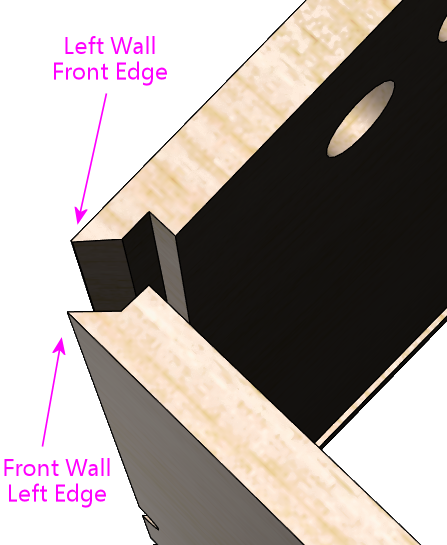

Double rabbet: This is a simpler option that you can make with

a table saw or a straight router bit. The double rabbet join

dispenses with the diagonal cut out to the corner, and instead uses

square interlocking notches. It's easier to construct, but it has a

couple of drawbacks. For one, it leaves a visible seam along one of

the joined faces. For another, it makes it a little trickier to

translate the cabinet measurements to the wood pieces, because of the

way one piece slightly extends the apparent length of the adjoining

piece.

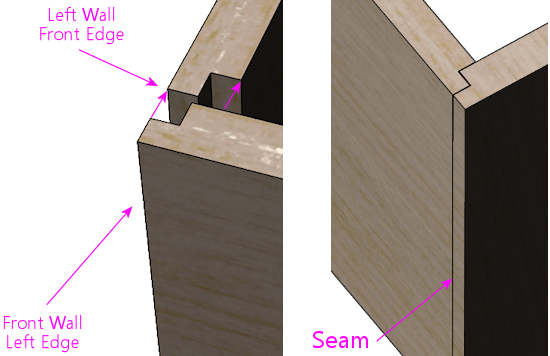

Double rabbet join, similar to the join used in Williams System 11 cabinets.

This is a simpler alternative to the lock miter join used in

the WPC cabinets, but it has the drawback that it leaves a

seam along one face near the corner.

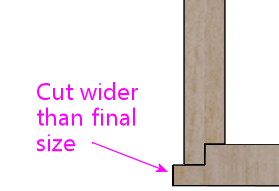

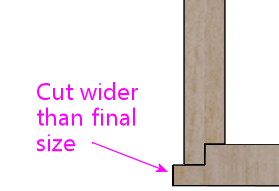

If you decide to use the double rabbet join, there are a couple of

things you can do to minimize the visibility of the seam. First,

choose the placement of the seam so that it's on the less visible

face. The seam only affects one or the other adjoining face at each

corner, so you have a choice of which wall will have the seam. The

Williams System 11 cabinets placed the seams on the sides (rather than

the front face), which seems like the better choice aesthetically,

since the front is more visible. Second, cut the front piece a tiny

bit wider (1/16", perhaps) than the final size, so that it leaves a

little overhang when initially assembled, as illustrated below.

After assembly, the overhang lets you sand down the excess material

until it's exactly flush with the adjoining section. It's almost

impossible to get the surfaces perfectly flush in the initial cut, so

your best bet is to start with a slight overhang that you can sand

until flush. You can then add wood filler at the seam to further

smooth it out.

Simple 45° miter: Some pin cab builders simply cut the ends of

the main cabinet walls at a 45° bevel angle, for plain miter

joins:

Woodworkers generally consider this an inferior join for large

cabinets, since glue is weak when joining end-grain to end-grain like

this, and because it's difficult to get the pieces aligned and squared

properly given the lack of any interlocking structure. Even so, it

might be viable for a pin cab if you're using the new-style Williams

leg brackets (part 01-11400-1), since they add a lot of corner

strength. I wouldn't personally use this join, but it's an option if

you want to simplify the woodworking.

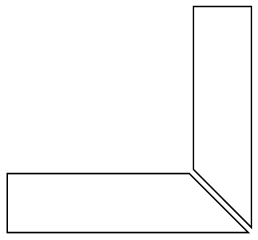

Adjusting dimensions for joinery

Pay close attention to the effects of your chosen corner joins on the

overall dimensions.

The dimensions shown in our plans assume that you're using a mitered

join of some kind for the main cabinet corners. Our illustrations

show those corners with a mitered rabbet, so you'll see that join in

the close-ups. Any miter join, including the locking miters and the

simple 45° miter, is equivalent in terms of all of the

measurements, so there's no need to make any adjustments for those.

With the mitered joins, note how each individual piece's dimensions

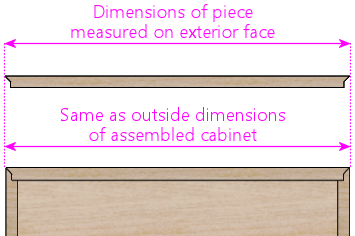

exactly match the assembled cabinet's outside dimensions for

that section:

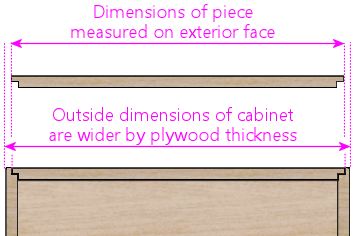

In contrast, with the rabbet join, note how the "inside" piece (the

one forming the face with the seam) is slightly shorter than the

assembled cabinet's outside dimensions. This will be shorter at each

corner by the depth of the rabbet groove, which is typically half the

plywood thickness, so assuming there's a join like this at each end,

the overall piece will need to be cut shorter than the desired final

outside dimensions by 2 × ½ × the plywood thickness =

1 × the plywood thickness:

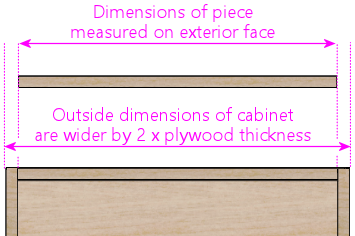

Likewise, for a butt join, the inside piece will need to be shortened

by 2 × the plywood thickness, compared to the finished outside

dimensions:

Our measurements for the main cabinet are based on using mitered joins

at the visible corners, so be sure to adjust the dimensions before

cutting if you're using a different join.

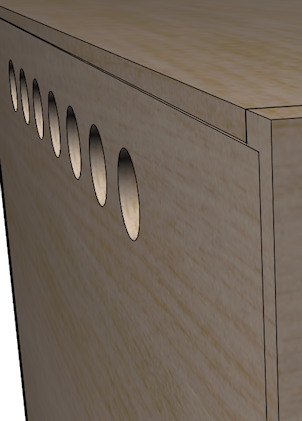

Edge finishes

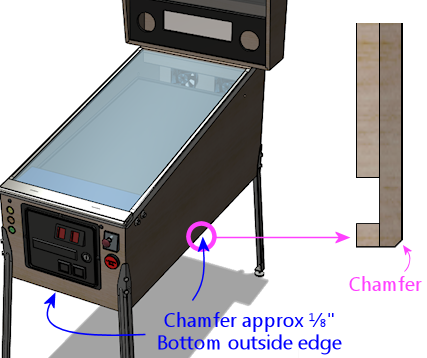

On the original WPC cabinets, the outside bottom edges of the side and

front walls are finished with a chamfer (a 45° bevel), about

⅛" wide. I don't think they did that for looks, but rather to

soften the plywood edge, to make it less sharp and splintery. On my

cab, I kept it simpler and just sanded the edges smooth. If you do

decide to apply a chamfer with a router bit, it might be a good idea

to test the bit on a piece of scrap plywood first - I've read that

some plywood will chip if you try to bevel the edge like this, and

that would defeat the whole purpose of smoothing it.

On the WPC machines, the front vertical edges (at the corners between

the front wall and the left and right walls) are square, without any

rounding or beveling. Some of the newer Stern machines round those

edges out slightly - it looks like they route the edge with a 1/8"

roundover bit. I just lightly sanded the corners on my cab until they

felt smooth.

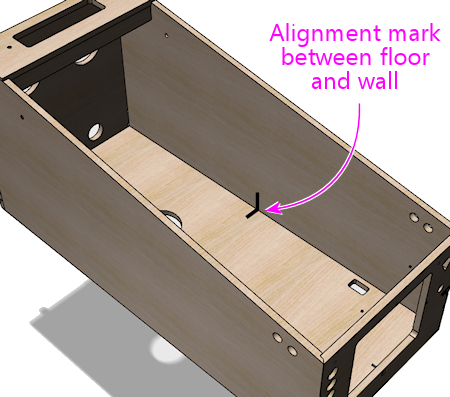

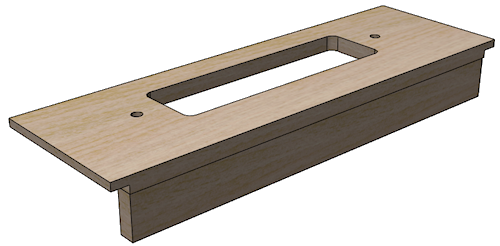

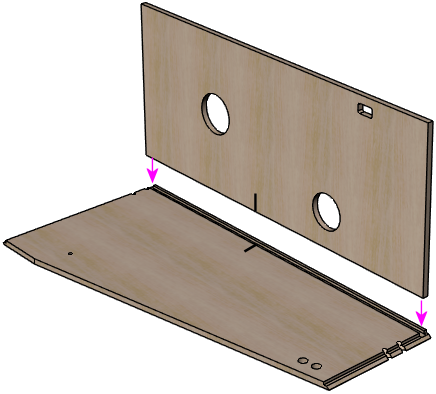

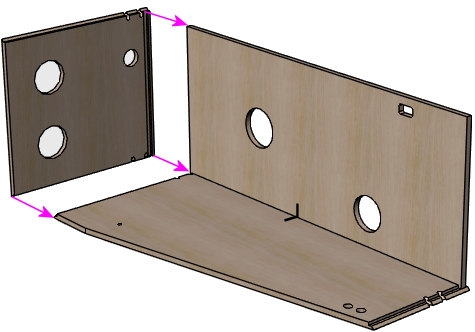

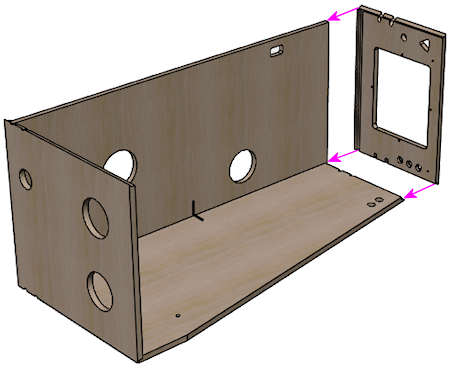

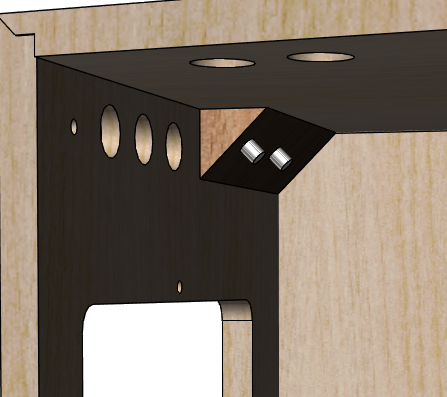

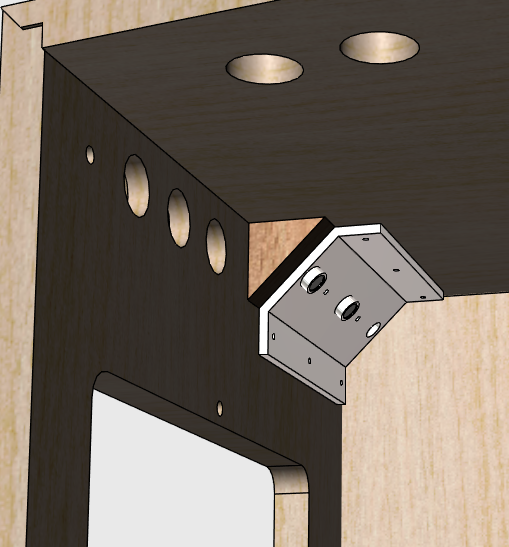

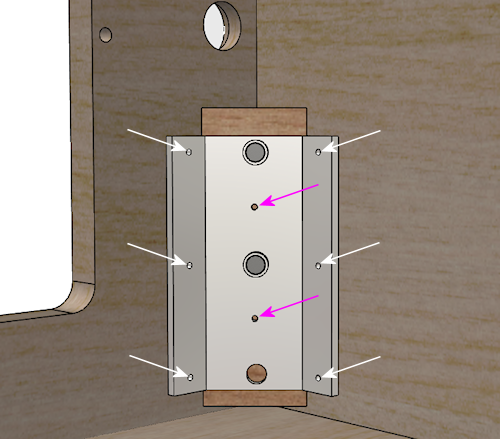

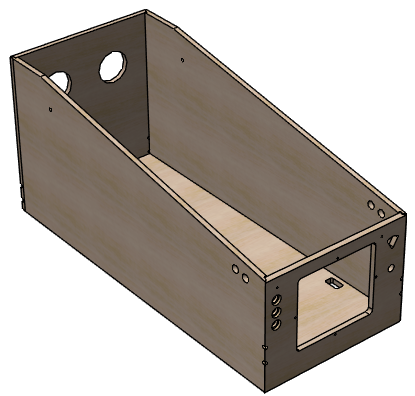

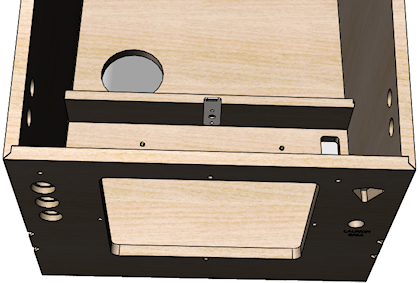

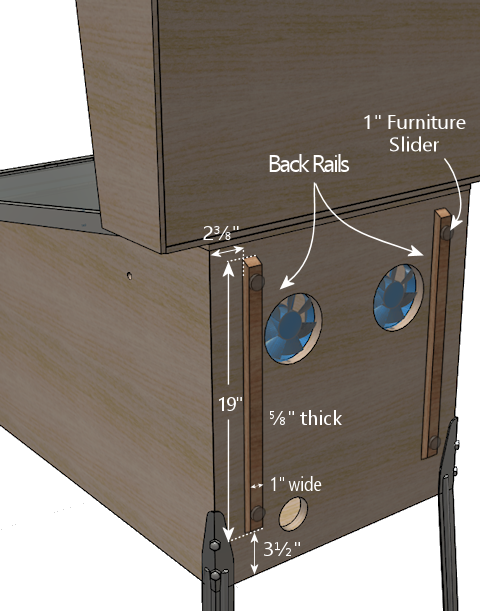

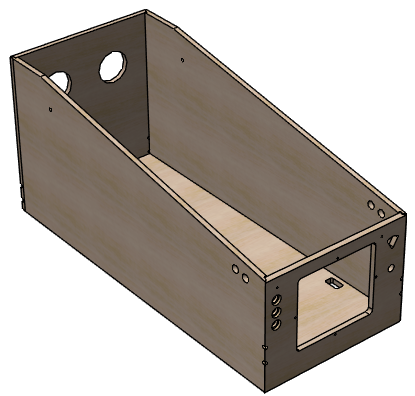

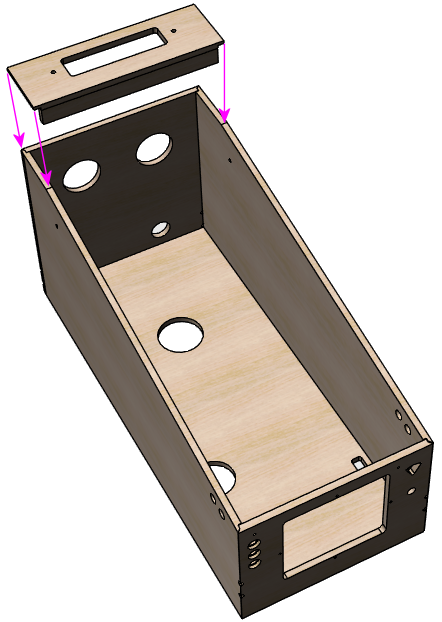

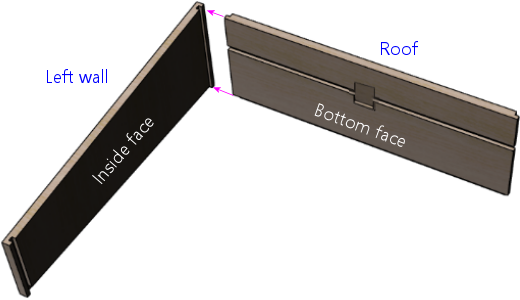

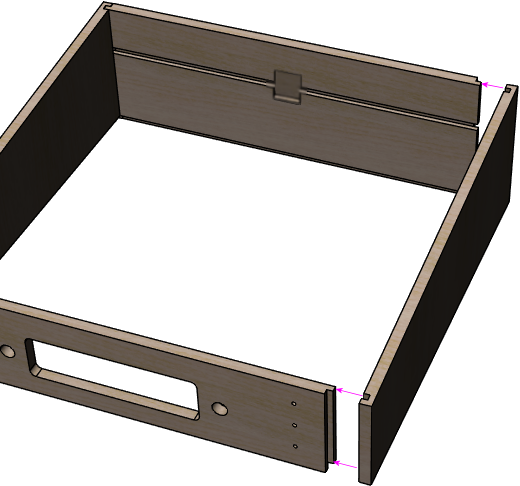

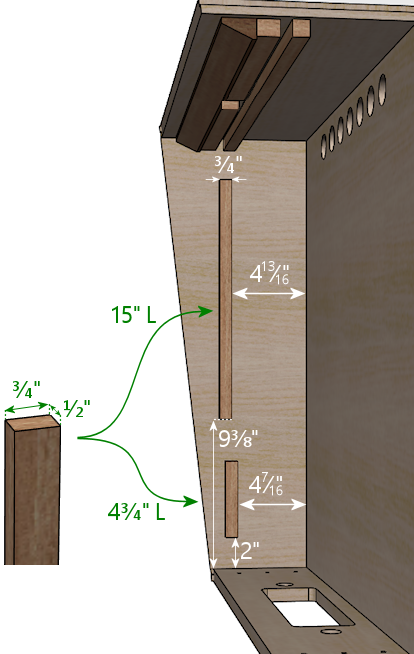

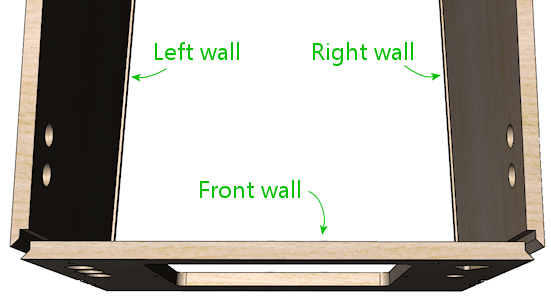

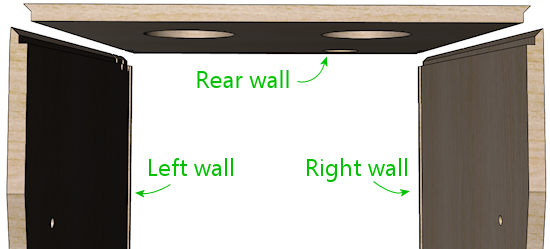

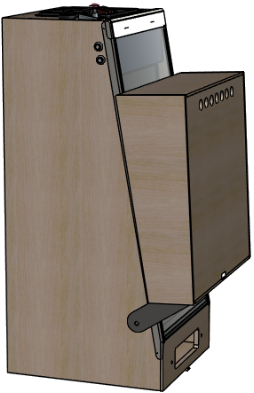

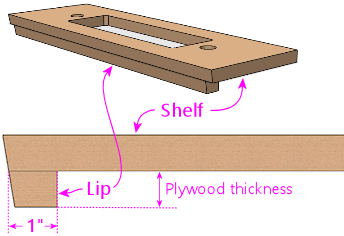

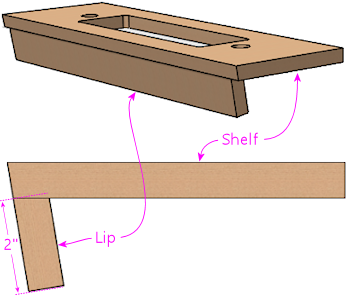

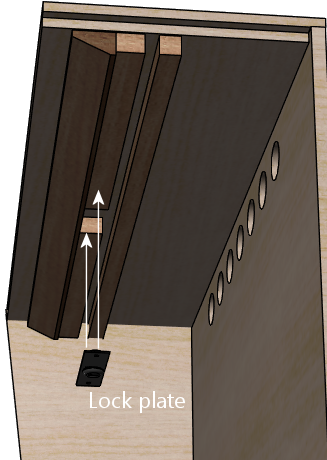

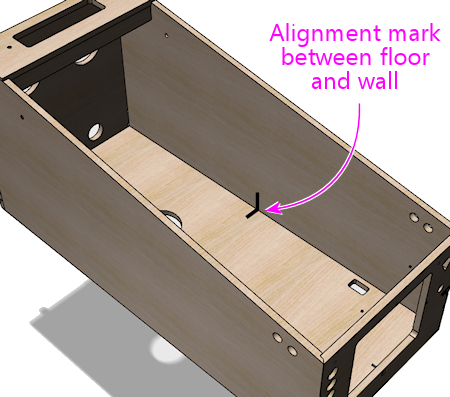

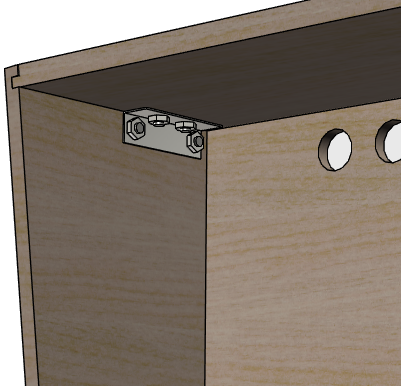

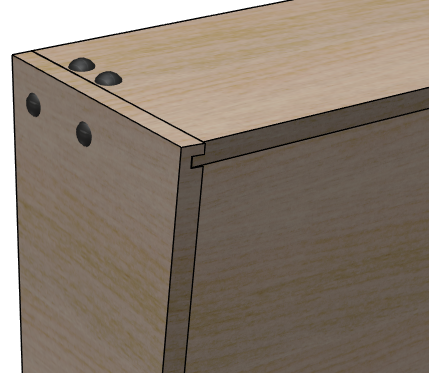

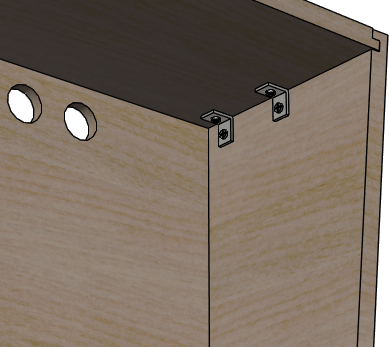

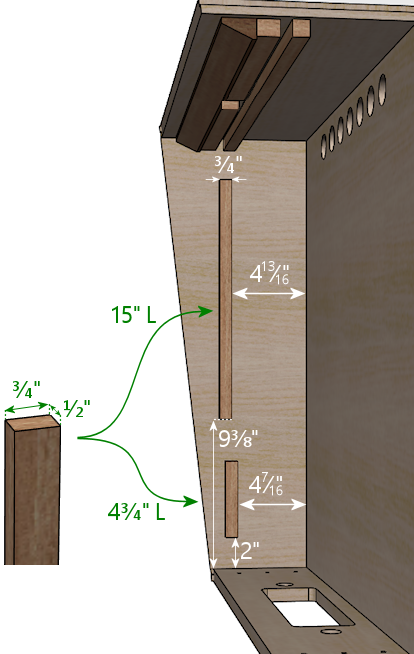

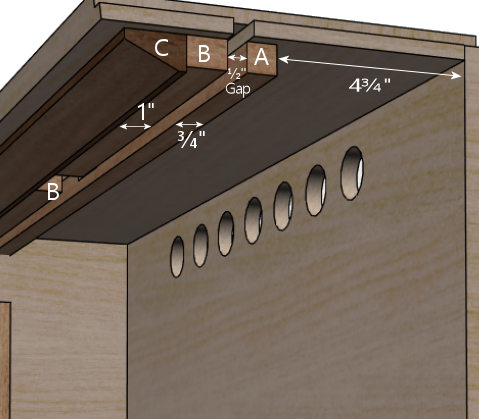

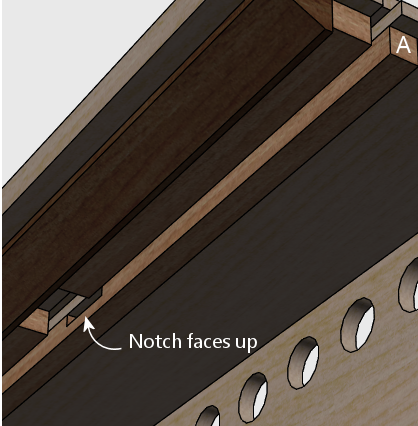

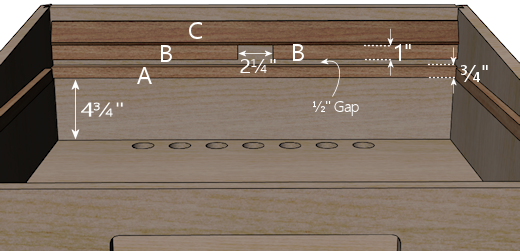

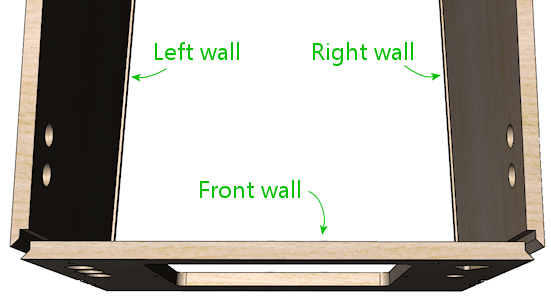

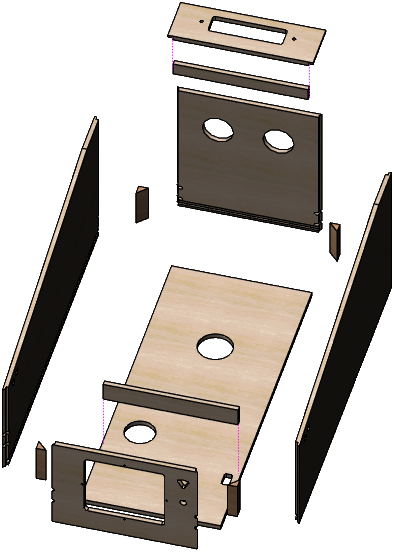

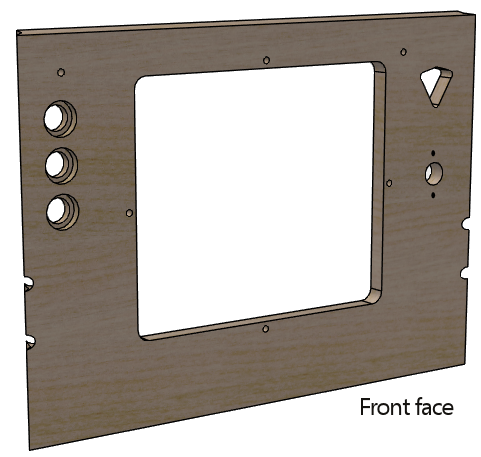

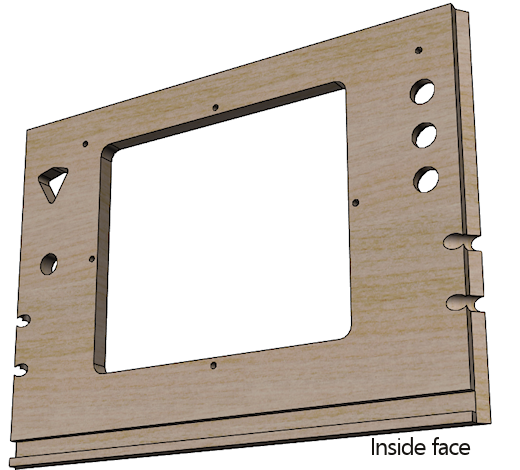

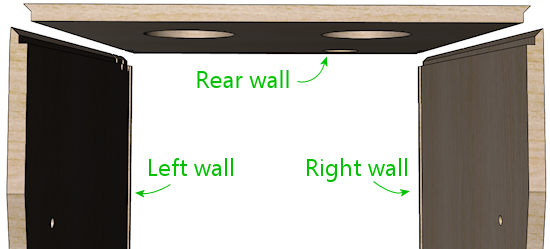

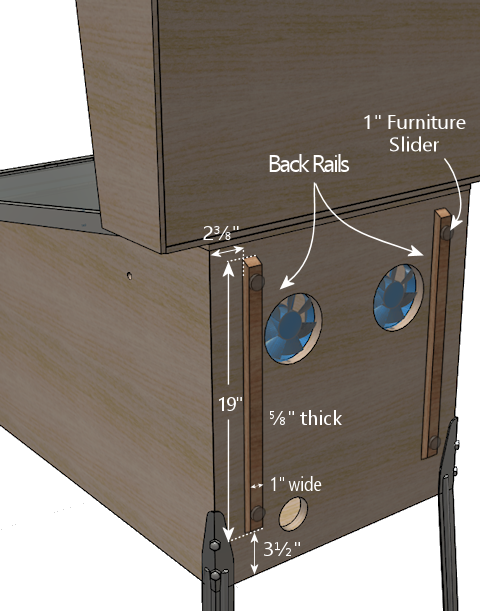

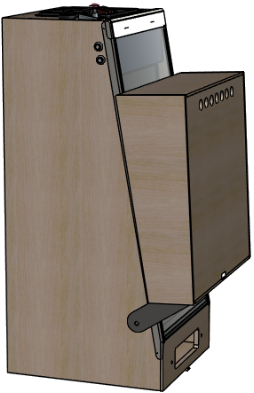

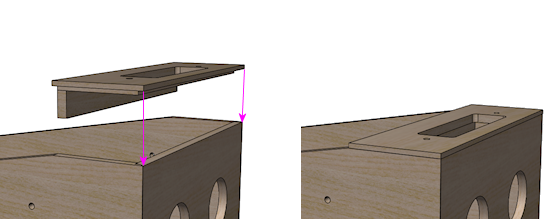

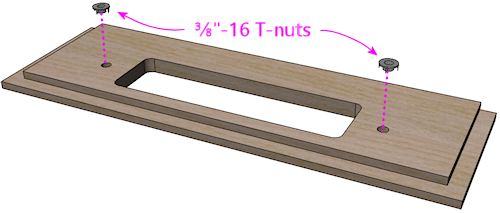

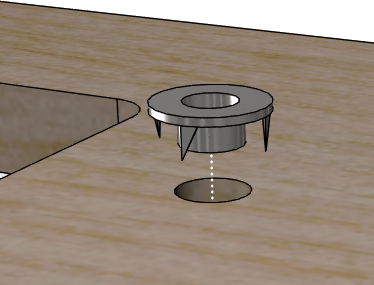

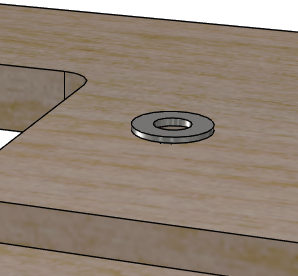

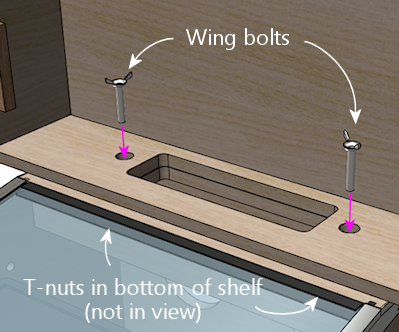

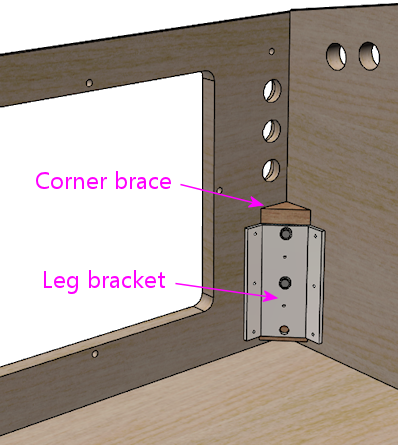

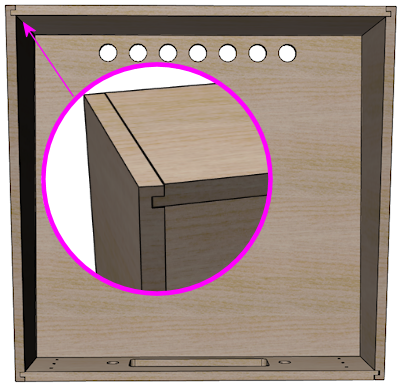

Exploded view

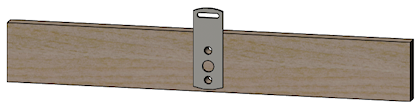

This view shows all of the pieces making up the

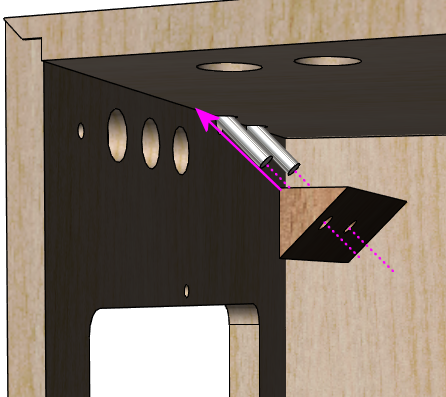

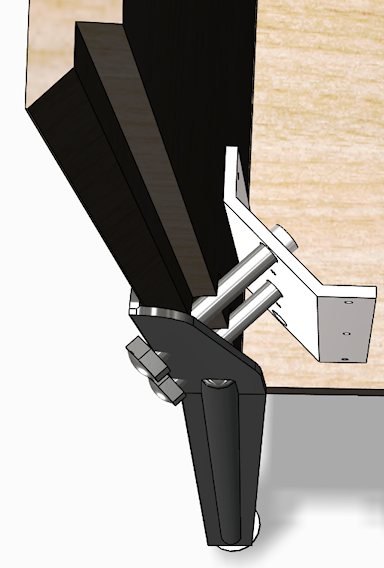

main cabinet body.

The triangular wood pieces at the corners go under the metal brackets

the leg bolts screw into. They provide reinforcement at the corners

(to prevent the corners from splitting) and help strengthen the leg

attachment. The leg bolts (two per corner) go through these at a

45° angle.

The two pieces at the top rear form a "shelf" that the backbox rests

on. The rectangular routed opening in the horizontal piece is to pass

power and video cables between the cabinet and backbox. The opening

shown is what's used on the real machines, and it works well for a

virtual cab as long as you only need to pass cables through. You

might need a larger opening, though, if you plan to use a large

monitor in your backbox that needs to extend into the main cabinet.

This isn't an issue for a typical three-monitor setup with a laptop

display for the DMD (or a real DMD device).

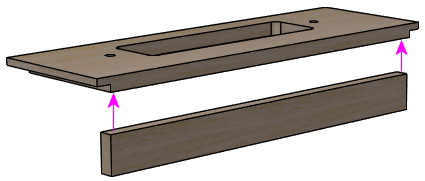

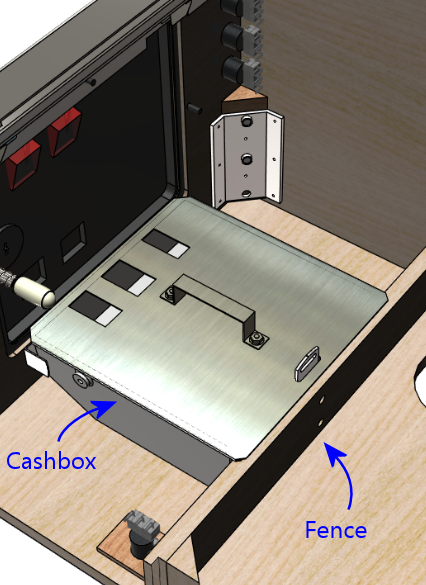

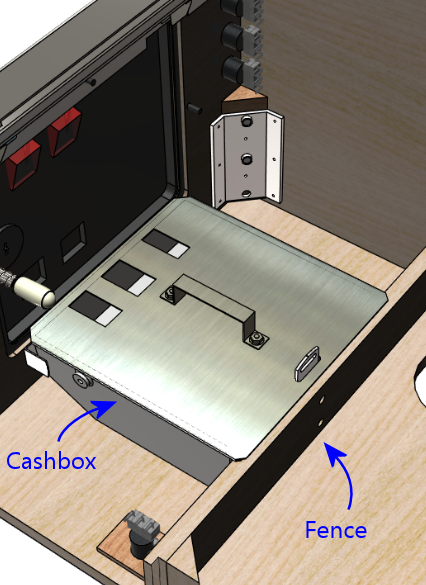

The smallish slat near the bottom front attaches to the floor on the

real machines to form a niche to hold the cashbox. (The cashbox

sits under the coin slots to collect the inserted coins.) Most

virtual builds omit this piece to leave more room for the PC

motherboard, which most people situate on the floor of the cab about

halfway back.

Cutting up the plywood

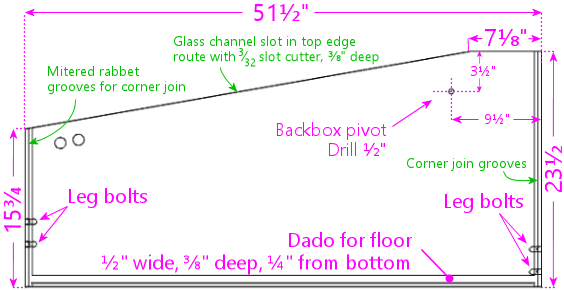

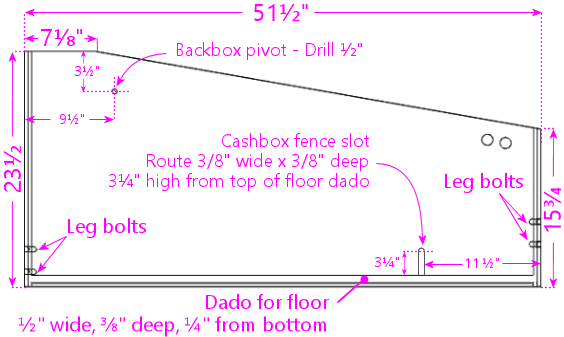

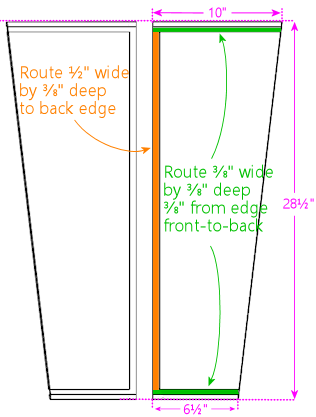

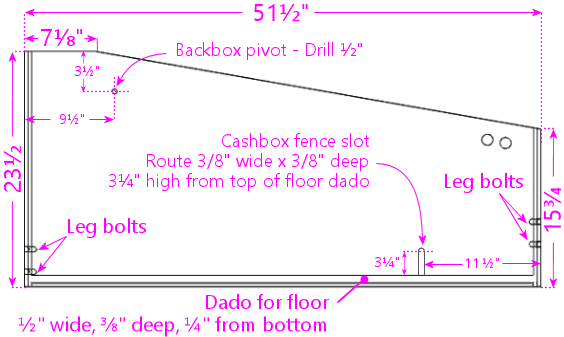

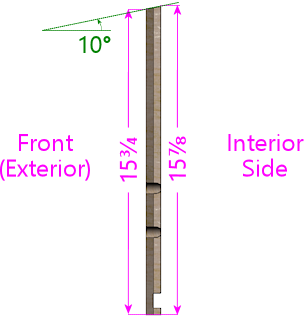

Side walls

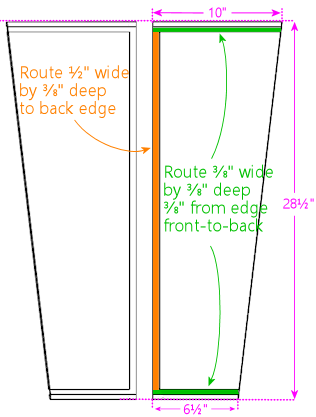

Here are the side walls. The views are from the interior of the

cabinet, to show details on the joinery routing.

(The flipper button holes and leg bolt holes are marked, but for the

sake of readability, the dimensions aren't shown here. We'll provide

close-up diagrams for these elements, with all of the measurement

details, later in the section.)

Left side wall, viewed from the cabinet interior side

Right side wall, viewed from the cabinet interior. The

right wall is a simple mirror image of the left wall.

Remember that we're measuring the dimensions of the pieces based on a

mitered join (either a mitered rabbet or lock miter) at the front and

rear corners, meaning that the piece's dimensions match the outside

dimensions of the assembled cabinet. If you're using a different join

at the corners, be sure to make any necessary adjustments. See

Joinery above.

Some more views to help with visualization:

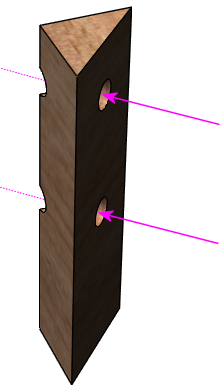

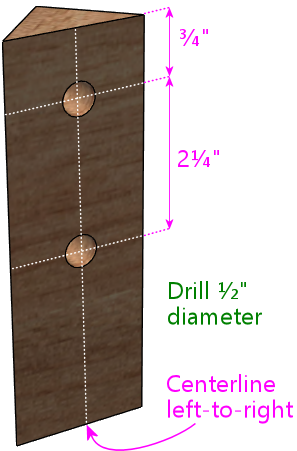

Backbox hinge pivot:

The backbox pivot is a ½"-diameter drilled hole for attaching

the WPC-style backbox hinge. If you're using a different hinge system

to attach the backbox, omit this.

Note: Some people prefer to wait to drill for the hinge pivots until

after assembling the cabinet and attaching the hinges to the backbox,

so that they can drill the pivots based on the actual assembled

alignment of the backbox. The procedure I've always used is basically

the opposite: drill the hinge pivot first, attach the hinges there,

and then drill the backbox bolts for the hinges based on the final

alignment. I haven't tried it the other way, so I'm not sure if that

would be easier or harder overall, but the basic idea is the same

either way. Use your discretion as to which approach sounds better.

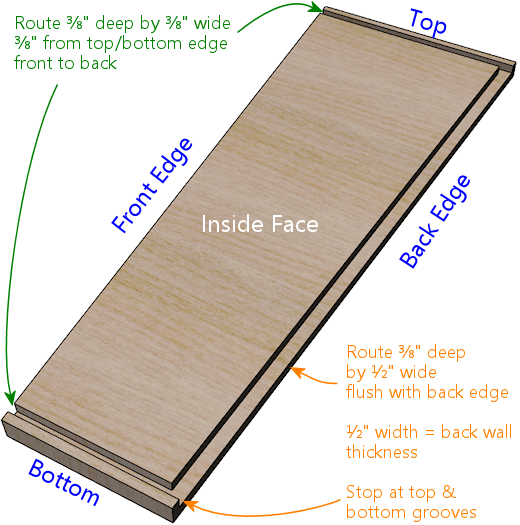

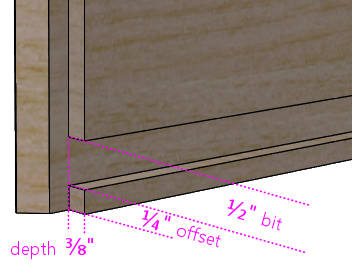

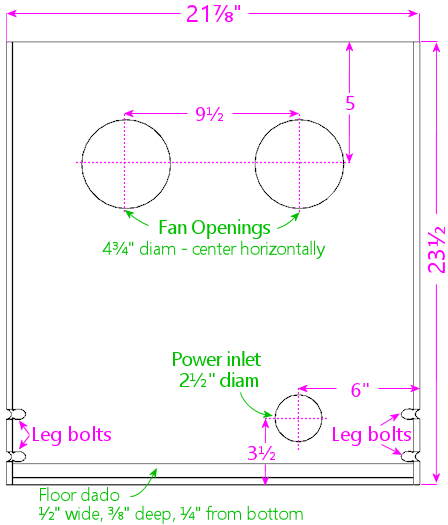

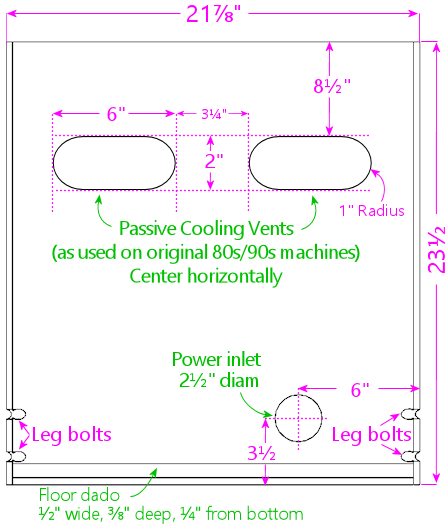

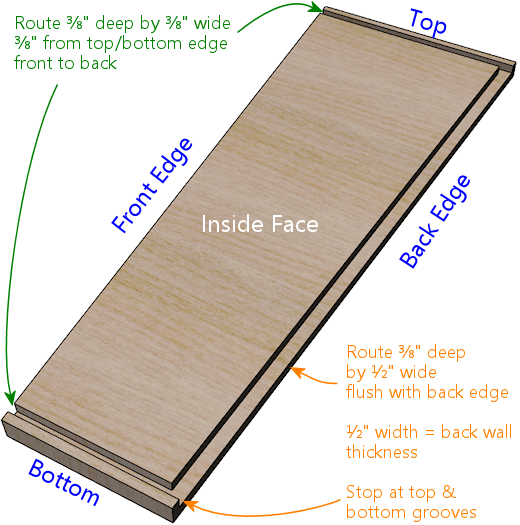

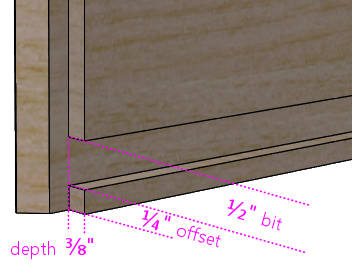

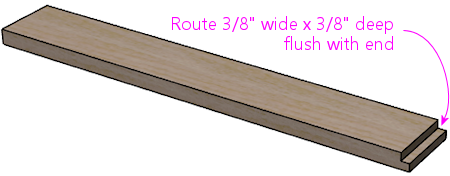

Floor dado:

The dado at the bottom is for the cabinet floor. Use a ½"

straight router bit to cut a groove ⅜" deep (halfway into the

thickness of the plywood), parallel to the bottom edge of the wall,

¼" from the bottom edge. This is on the inside face of

the wall; the edge of the cabinet floor fits into this groove when

assembled.

Left cabinet wall showing the dado (groove) for joining with

the cabinet floor. Route the dado with a ½" straight bit

to ⅜" depth, ¼" (or ⅜", if you prefer) from the bottom edge. This groove

runs the whole length of the side wall. This is on the interior

face, since it joins with the cabinet floor. The diagonal/step

shape along the vertical edge at the left is the mitered rabbet cut

for joining to the front wall, illustrated in more detail above.

Note: Some other people's WPC-replica plans show the floor dado at

3/8" from the bottom, rather 1/4" as depicted above. My original WPC

cabinets measure 1/4", but I measured one older System 11 machine at

3/8". The larger 3/8" offset will make the joint a little stronger,

and shouldn't much affect anything else, so I don't see any downside;

use your discretion. Whatever you decide, be sure to route the

corresponding dados in the front and back walls at the same offset,

since they all have to align when assembled.

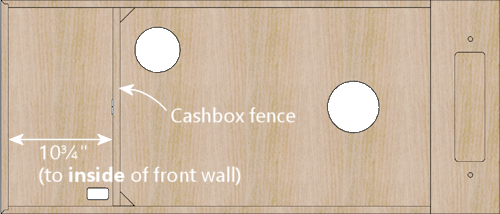

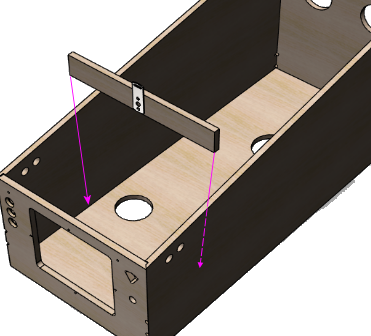

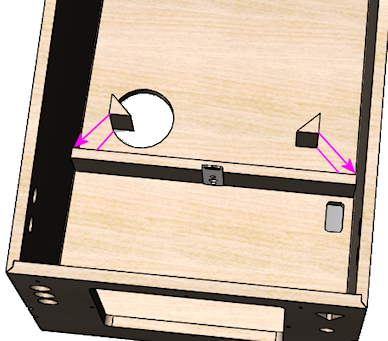

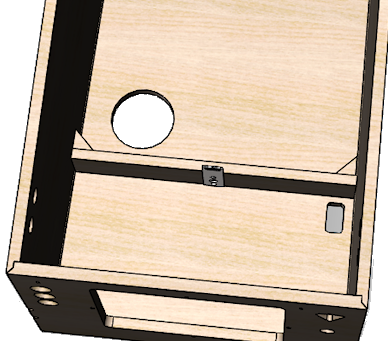

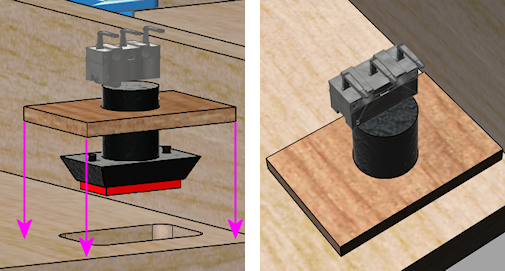

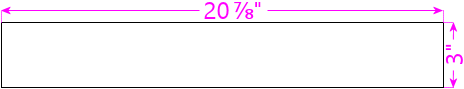

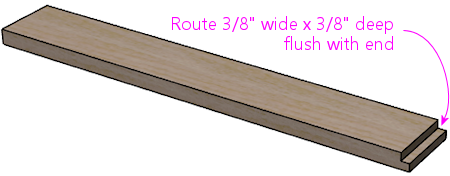

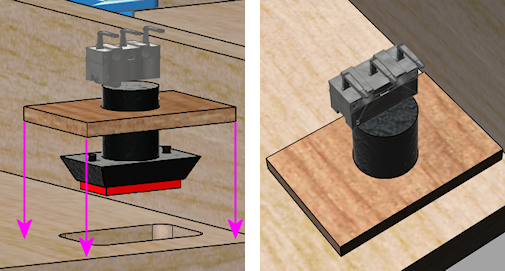

Cashbox fence slot:

The slot for the

cashbox fence is only

needed if you plan on installing said fence, which is useful if you're

going to use the standard type of coin collector box ("cashbox") made

for commercial pinball machines. The cashbox sits at the front of the

cabinet under the coin slots, and the fence helps hold it in place.

Most virtual cab builders don't use the standard cashbox because it

takes up so much space. I'd omit the fence if you're not going to

use the standard cashbox.

The routed slot isn't strictly necessary even if you do include the

fence, but it makes it easier to install the fence during cabinet

assembly by providing an anchor point to glue it to.

The slot only goes in the right wall. You can move it to the left

wall if that's more convenient - it really doesn't matter which side

it's on. But you only need a slot on one side or the other.

If you're going to use a custom cashbox that's not the standard size,

you should move the fence (and thus the fence slot) to match the

depth of the box.

Edge finishes

The original WPC cabinets use a slight chamfer (a 45° bevel) on

the outside bottom edges of the side walls, to soften the edge and

reduce splintering. This is optional, but it will reduce the chances

of snagged clothes and cuts from bumping into the side.

See

Edge finishes above.

Leg bolts

The leg bolt holes are a little tricky. The bolts go through the

corners at a 45° angle, so they bore through both adjoining walls

at each corner. So, as shown in the illustration, the left and right

walls only have "half a hole" for each bolt - really more of a

semicircular notch.

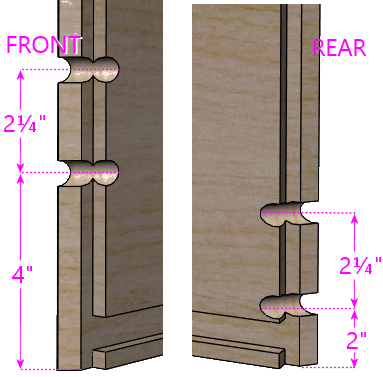

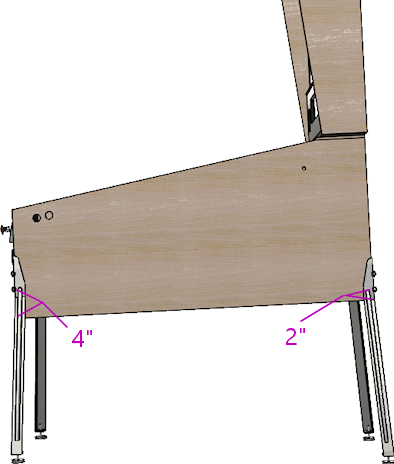

Leg bolt holes, front (above left) and rear (above right).

The distances are shown from the bottom of the cabinet. Note

that the front legs are mounted higher on the wall than the

rear legs. The legs themselves are the identical parts front

and back, so the different mounting position is used to give

the cabinet its characteristic tilt angle. The bolts

are 3/8" diameter.

Cutaway view (with the front wall removed) showing the leg

bolts installed, to better illustrate how the bolt holes

intersect the side wall. The triangular wood piece that

normally fills the gap between the metal plate and the

inside wall is also hidden.

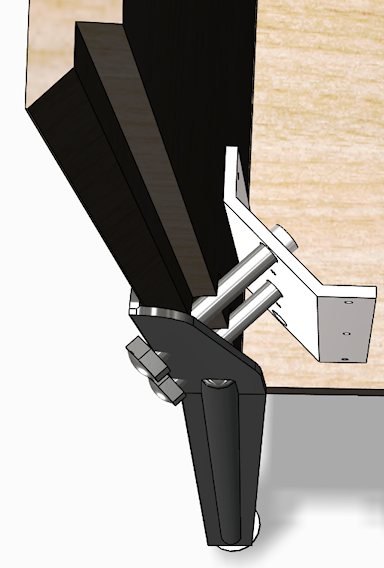

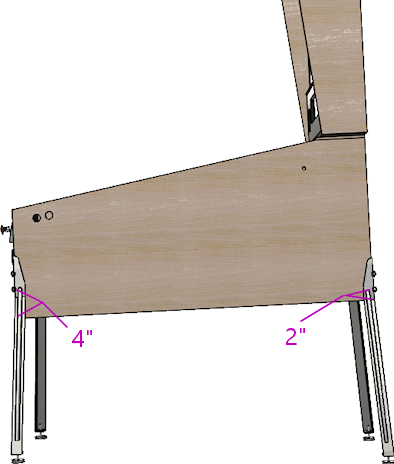

Illustration of how the leg install positions affect the

cabinet slope.

The legs are mounted higher on the cab in the front,

which effectively raises up the back end slightly to slope

the machine down toward the front. Standard

pinball legs come with adjustable foot pads that you can use to

make sure all four legs touch down and to fine-tune the

playfield slope. The slope isn't needed for "physics"

reasons on a virtual machine, but it's still desirable

for an authentic appearance, and it also improves the

viewing angle for the main TV.

There are two approaches to drilling the holes:

Preparing to drill for a leg bolt at the front right corner,

using a general-purpose drill guide block. This drill block features a notch

specifically for drilling into a corner at a 45° angle.

I'm using a band clamp wrapped around the whole cabinet to

hold the drill block in place. You have to clamp the drill

block down pretty tightly, and even then you have to be careful

to use a steady hand - those 45° notches are small, and

the drill gives you a lot of leverage.

Personally, I find the "before" approach too difficult to do by

hand, because of the 45° angle and because you have to get the

notches on the adjoining edges align perfectly. This is

probably only workable if you're making the panels with a CNC machine.

I'd go with the drill-after-assembly approach otherwise.

With either method, the holes should end up being a tight fit for the

bolts. That's good, since you don't want the legs to be wobbly on a

250-pound cabinet. But if they're too tight, try rubbing a little

paraffin wax or a similar dry lubricant on the bolts. (I wouldn't use

anything oily or greasy.) If that still doesn't work, you can use

a small round file to expand the holes slightly - but as little as

possible, to avoid weakening the corner.

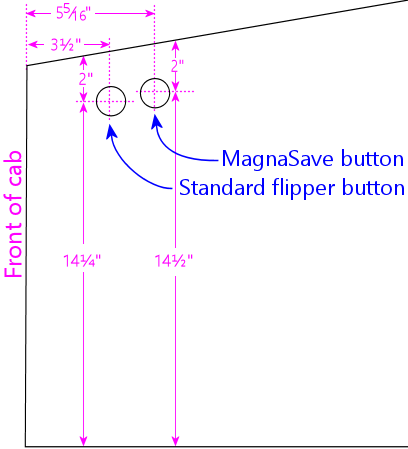

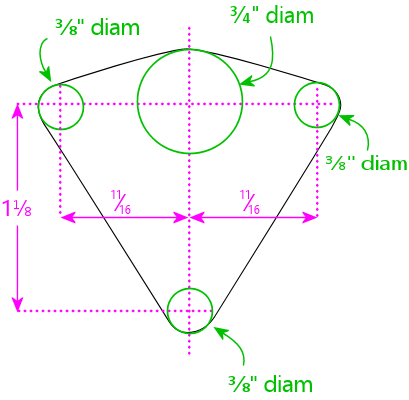

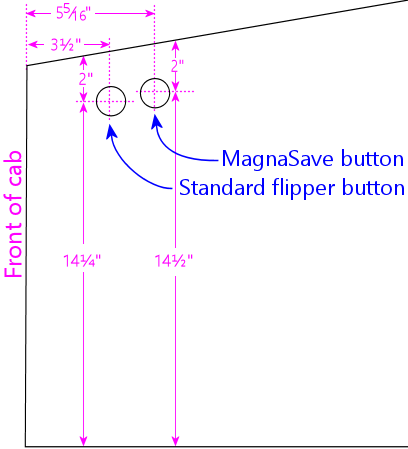

Flipper buttons

Here's the drilling plan for a set of two flipper button holes on each

side. The front button in each set is the regular flipper button, and

the rear button is the "MagnaSave" button, which is for the benefit of

some pinball games that have extra controls beyond the regular flipper

buttons. The rear buttons are optional, and not everyone likes them

since they're not all that common on real machines, but I think it's

good to include them because of the large number of virtual tables

that make use of them. See

Tables with MagnaSave Buttons for more

about these buttons, and a list of some of the tables that use them.

Note! Some side rails are wide enough to cover the flipper

buttons, in which case they'll come with pre-drilled holes for

the buttons. The WPC rails are narrow enough that they sit

entirely above the flipper buttons, so they don't need any

holes for the buttons. If you're using wide rails that do

cover the flipper button area, ignore our drilling locations!

Your cabinet flipper button holes need to line up with the ones in the rails.

So use the button holes in your rails to determine where to drill.

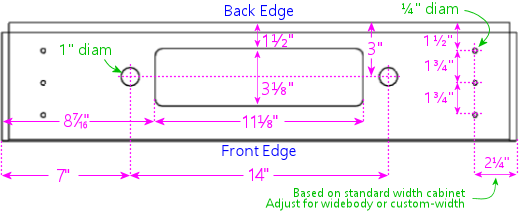

Flipper button drill hole detail for WPC-type side rails.

Measurements are in inches; distances are to the center points

of the holes. (Don't use these locations if you're using older

side rails that cover the flipper buttons. Instead, use the

pre-drilled flipper button holes in your rails as drilling templates,

so that the cabinet holes line up with the holes in the rails.)

The distances in the diagram are measured are from the center of the

drill holes to the front and top edges of the wall, square with the

front edge. The measurements are referenced to the outside

face of the fully assembled cabinet. If you're measuring prior to

assembly, make any adjustments needed to account for offsets from your

front corner joins. Mitered joins shouldn't require any adjustments,

since the outside edges of all faces go all the way to the corners.

Don't rely on the locations in the diagram if you're using wide side

rails that extend over the flipper buttons. Those come with

pre-drilled holes for the flipper button, so you'll need the cabinet

wall drill locations to match the pre-drilled rail holes. Do a dry

fit with the rails to determine the drilling location.

How to drill:

- The easy way: drill straight through with a 1⅛" diameter hole

saw or Forstner bit. This works only if you're using something to

anchor the button on the inside, such as the VirtuaPin flipper switch

bracket or an LED board (see Button Lamps) to illuminate the button.

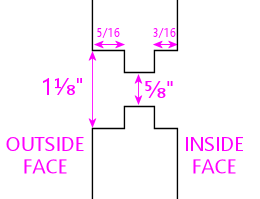

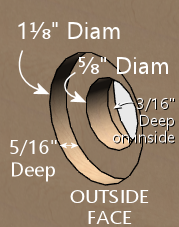

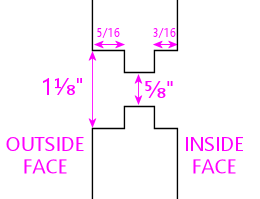

- The original way (used on most of the real machines): This

pattern has a narrow waist for the stem of the button, and larger

insets on the outside and inside for the body of the button and

the Pal nut, respectively.

- Drill a small pilot hole (1/8") on the center, all the way through

- Use a 1⅛" hole saw, Forstner bit, or router bit to drill a

5/16"-deep depression from the outside, on the same center

- Use the same 1⅛" bit to drill a 3/16"-deep depression from the inside

- Drill the rest of the way through with a ⅝" bit, on

the same center

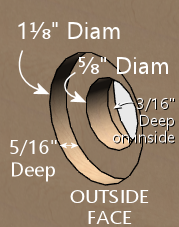

Schematic diagram of the "original" flipper button drilling

pattern. This is an edge-on view of the side wall.

The original "stepped" pattern lets you fasten the button with a Pal

nut, without any additional brackets on the inside. Use this pattern

if you don't plan to use an LED board or switch holder bracket. The

straight-through approach is better if you're planning to use an LED

board to illuminate the button, since it provides a tunnel for the

light to shine through. But you need some sort of bracket on the

inside in this case, because the Pal nut fits through the larger

1⅛" hole. An LED board can serve as the bracket, as will a

VirtuaPin flipper switch holder. If you're not planning to use one of

those, the original stepped pattern is better.

Variations:

- The rear (MagnaSave) buttons are optional. If you don't want to

include them, simply don't drill the holes. The regular flipper buttons

go at the same position whether or not you include the MagnaSave

buttons.

- There are at least two other good ways to position the MagnaSave

buttons. Some people place them directly below the flipper buttons,

and some people prefer them diagonally behind and below the flipper

buttons. Both of those patterns have precedents in real pinball

machines that had the extra buttons (see

Tables with MagnaSave Buttons). The layout in my diagrams is based on

the Williams MagnaSave games from the 1980s, so it's probably the most

familiar look to most players, but not everyone likes the feel, due to

the stretch to reach the rear buttons. The more vertical layouts are

arguably easier to reach, and make it it easier to keep a finger on

each button.

- Williams System 11 games (1980s) placed the flipper buttons about

1/4" higher than shown in my diagrams, which are based on the WPC

games (1990s). System 11 games used broader side rails that

covered the flipper buttons, so I think the slightly different

positioning is purely to accommodate the different rails. I don't

think it noticeably affects the feel.

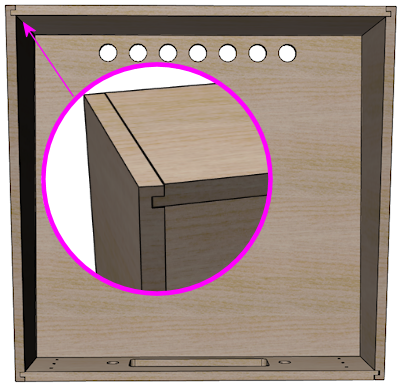

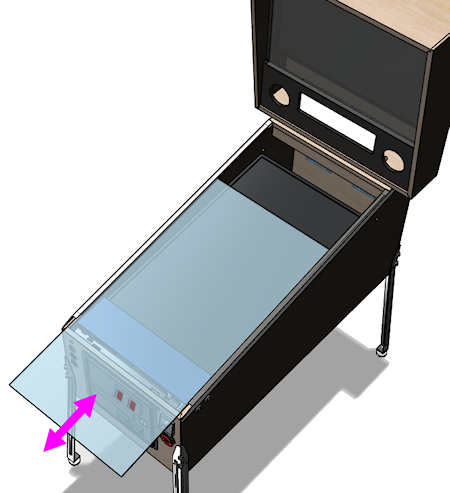

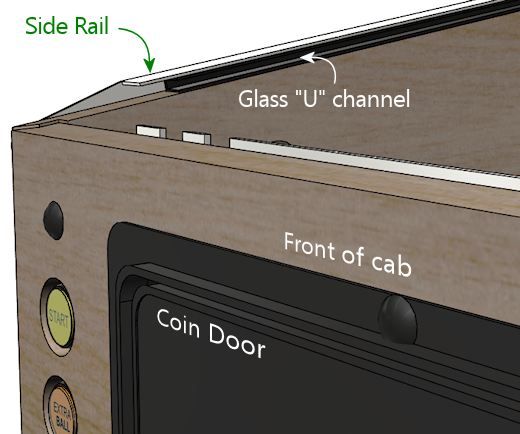

Glass channel slots

If you're going to install the standard side rails and a glass cover

over the playfield, you should also install a set of "glass channels".

These are plastic "U"-shaped trim pieces that fit under the side

rails, along the left and right edges. These hold the glass at the

sides.

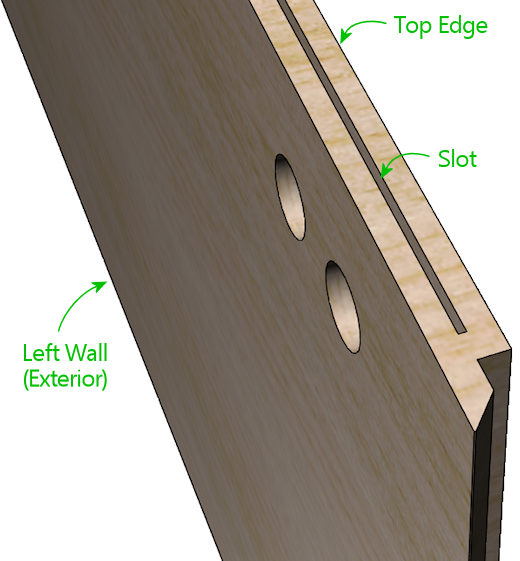

Because the glass channels are "U" slots along the length of the

machine, you can slide the glass in and out of the channels through

the front of the machine, after removing the lockbar. This is part of

the tried-and-true design of the real machines that lets an operator

easily open up the machine for maintenance access, and I think it's

a great thing to replicate in a virtual cab.

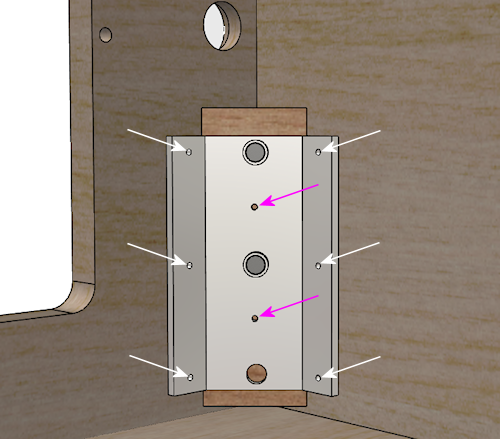

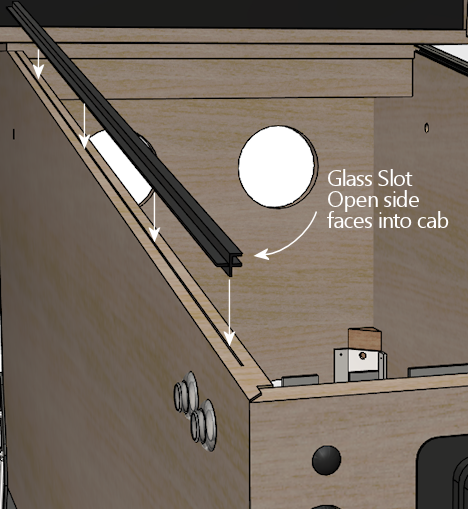

The glass channels are installed under the side rail. Here's a

close-up of how they look when installed:

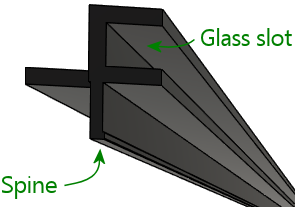

The channels attach to the side wall via a "spine" sticking out of the

bottom of the plastic channel. The spine which fits into a slot in the

top edge of the side wall.

This is a neat design, in that you don't need any fasteners or

adhesives. You just press the spine into the slot, and it's held

there by friction. If it's ever necessary to take the channel out,

you can just pull it out. On the other hand, it presents us with

another little wood-working challenge: how do we cut that precise

little slot?

As usual, it turns out that there's a special tool for this job, and

it's really easy once you have that magic tool. What you need in this

case is a special-purpose router bit called (naturally) a slot cutter.

Just as a drill bit is designed to drill a hole of a specific

diameter, each slot cutter bit is designed to make a slot of a

specific width and depth. For this job, you need a bit with a 3/32"

slot width and 3/8" slot depth. (A deeper slot, like 1/2" or 5/8",

will also work if you can't find a bit for that exact depth. But the

width is important - it should be exactly 3/32".) The bit I use

for this is Freude part #63-106, which works perfectly.

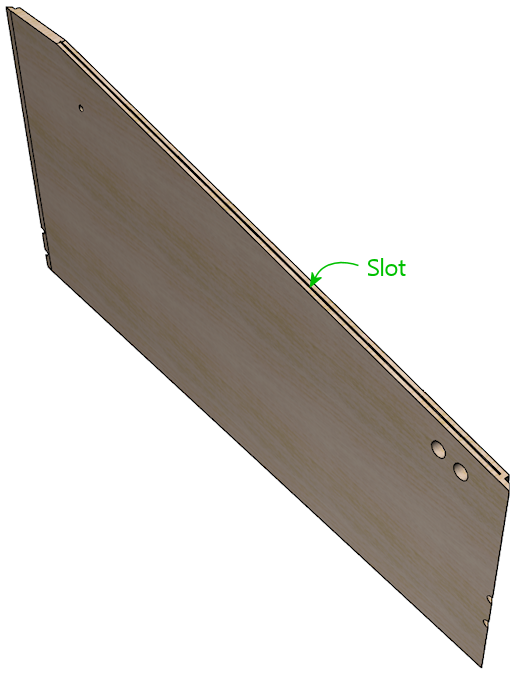

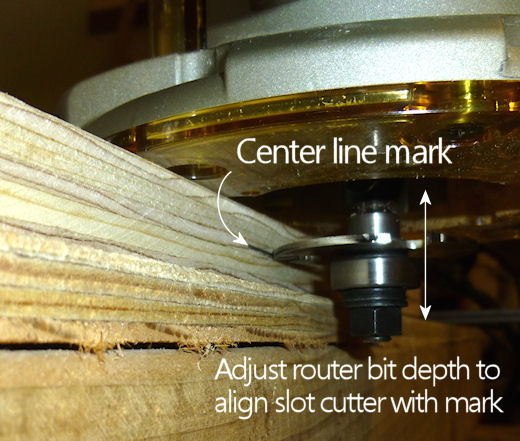

Once you have the necessary slot cutter bit, cut a slot along the top

edge of the sloped portion of each side wall, centered along the edge,

starting about 1½" from the front and ending at the top of the

sloped section. The photos below give an overview of how you set up

the bit and cut the slot.

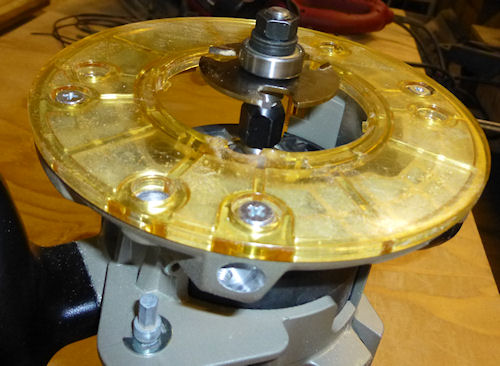

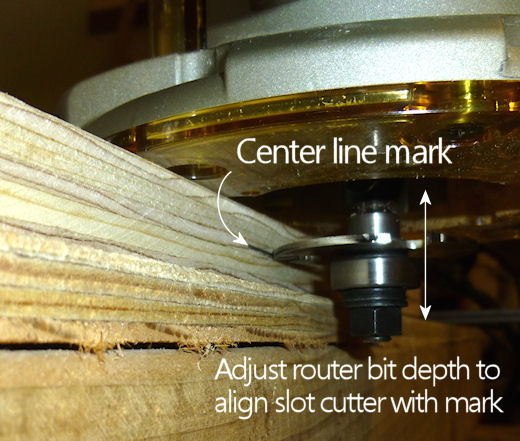

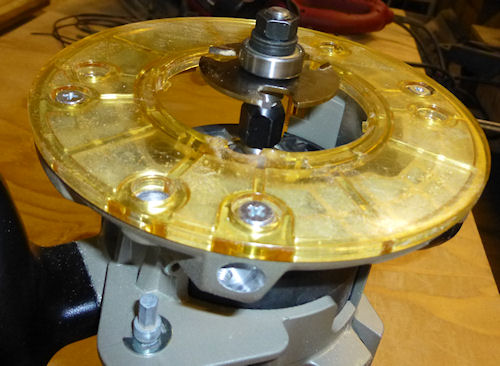

Slot-cutter bit, 3/32" slot width, 3/8" depth (the photo shows a

Freude #63-106, but other brands are available with the same specs)

The slot-cutter bit set up in a hand router. This bit works best

with a fixed-base router. A plunge router will also work -

you just have to lock the depth. You can also do this

with a router table, using your router table's setup for a bit

with a pilot point. I'm using a hand router for these illustrations,

since I've found that to be an easy way to use this bit,

but the process is essentially the same with a table.

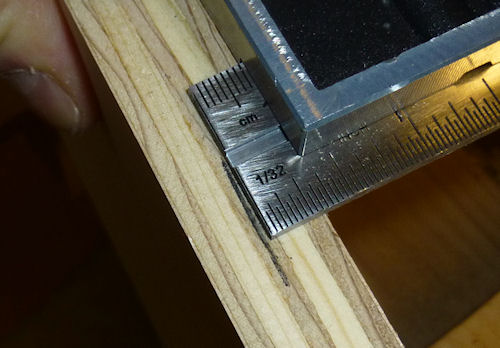

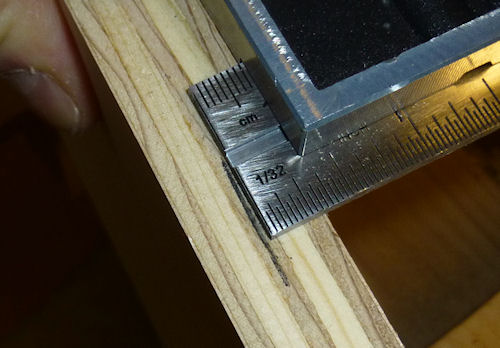

Measure the thickness of the plywood, and mark the centerpoint.

To make sure you found the exact center, flip the board over

and measure the same distance from the other side. Adjust your

measurement and repeat until the center mark is accurate.

Now clamp the board to a horizontal surface. Make sure the

router is unplugged! Place the router base flat on top of the board,

with the bit against the edge. Using the router's cut depth

adjustment (see your router's instructions), adjust the bit

depth so that the slot cutter blade lines up with the center

line you marked in the previous step. Lock the router at this

depth - this sets the bit to cut the slot at the center of

the board's edge.

You're all set to cut the slot. Plug the router in. Make sure

the board is securely clamped to a horizontal surface. Place

the router flat against the board with the bit hanging over

the edge right next to the starting point for slot. For safety,

always make sure that the bit isn't touching the work piece

(or anything else!) when you switch the router on - so

position it so that the bit is just clear of the work piece,

at the point you want to start the cut, with the base flat

against the board. Keep the router base flat against the

board at all times throughout this procedure, and hold

the router in both hands to keep it steady. When the router is up to speed, gently

slide it sideways into the edge of the board to start cutting

the slot. The bit's pilot point will automatically stop

the bit at the correct slot depth, so just keep sliding

it into the edge until it hits the pilot point. Now slowly

move the router along the edge of the board, parallel to

the edge, keeping the pilot point pressed against the edge,

until you reach the end of the span where you want the slot

to be. Finally, withdraw the bit from the slot, by sliding

the router sideways away from the edge of the board just far enough

for the bit to move clear of the slot, then turn off the router.

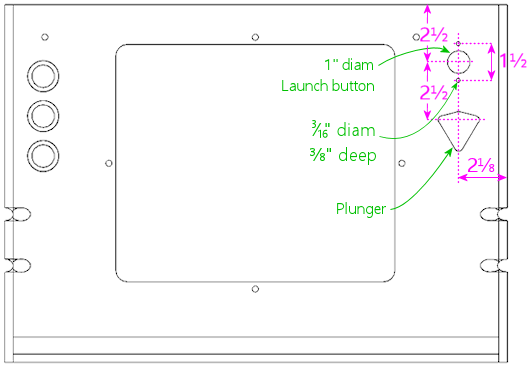

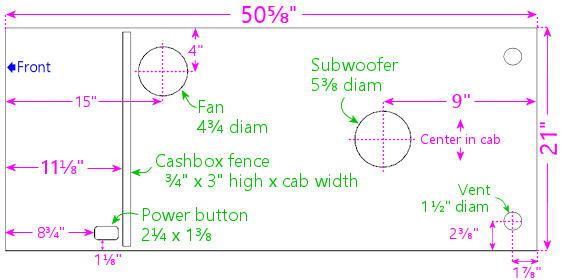

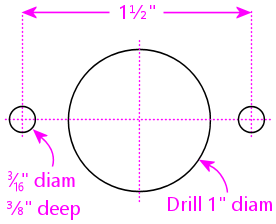

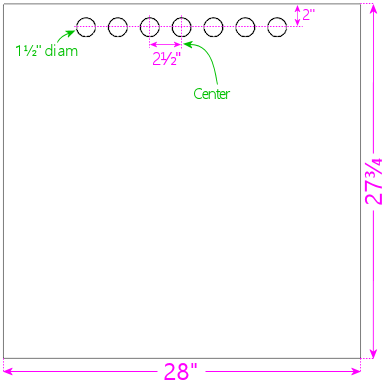

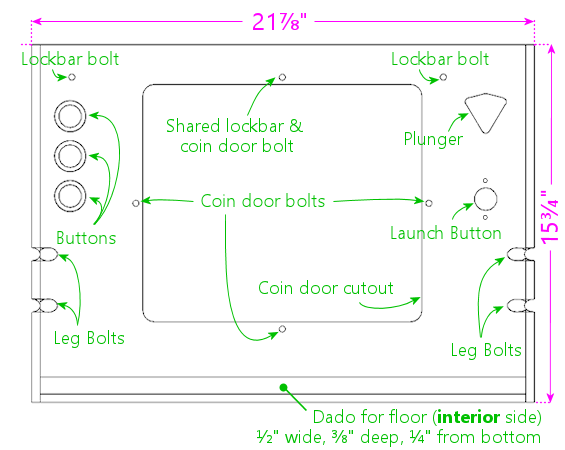

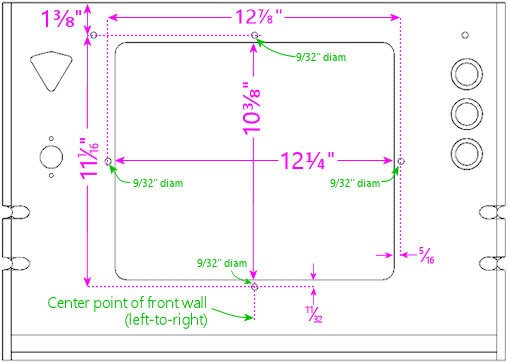

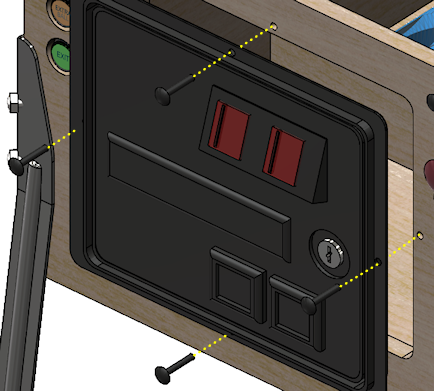

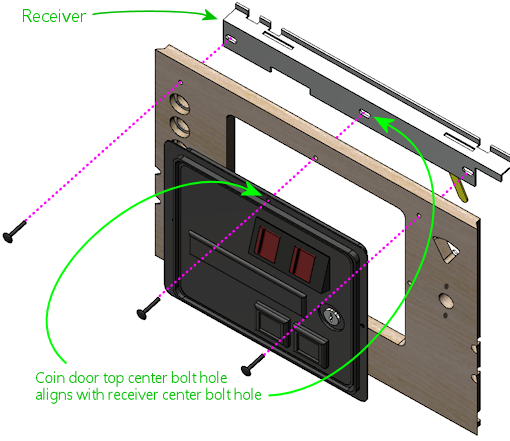

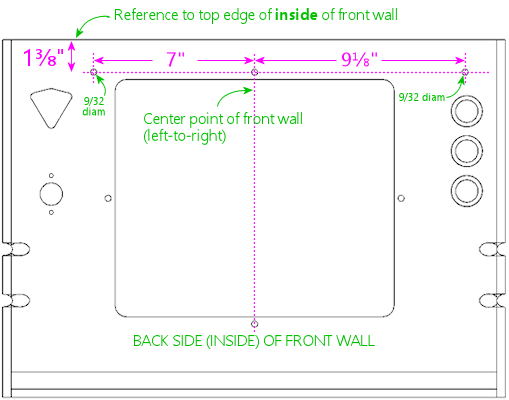

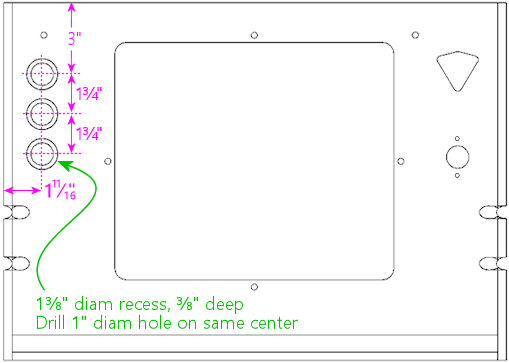

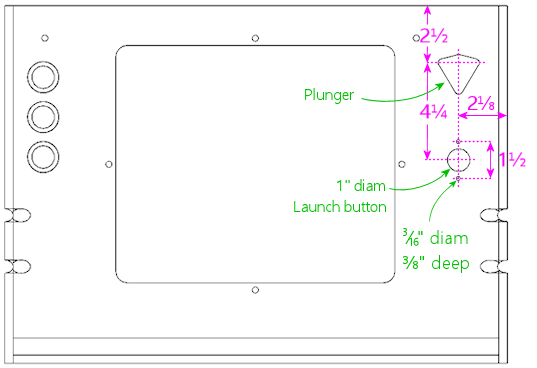

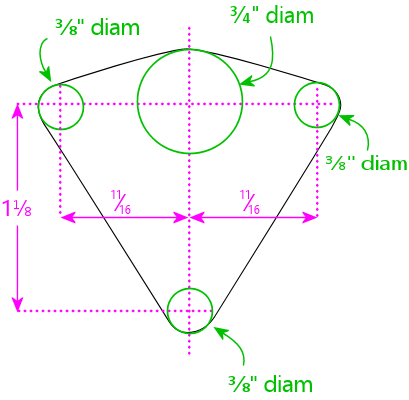

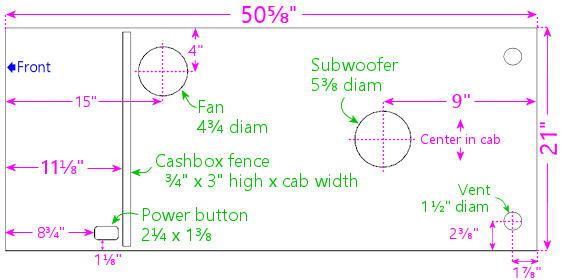

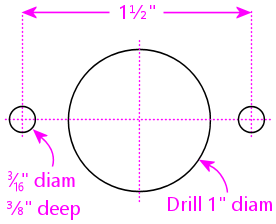

Front wall

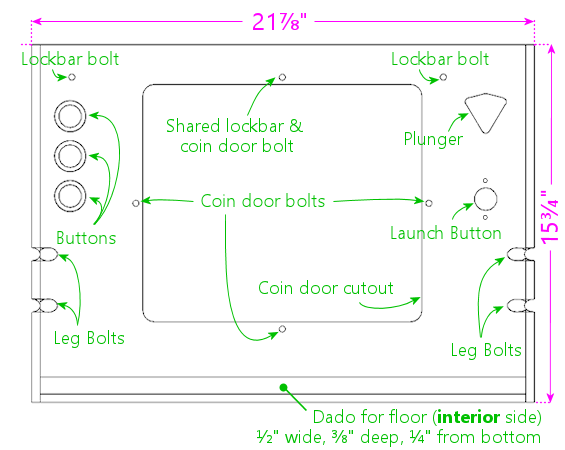

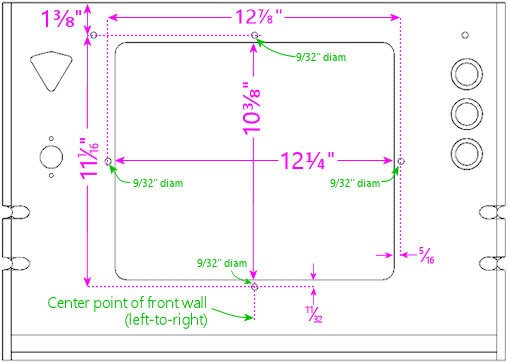

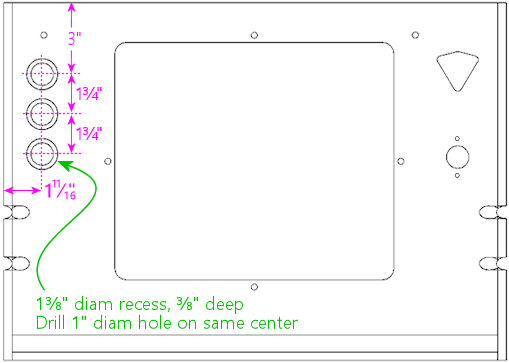

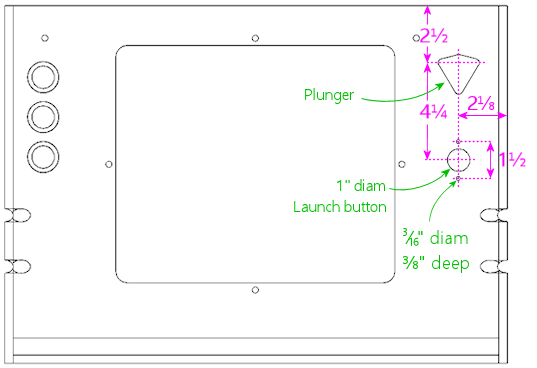

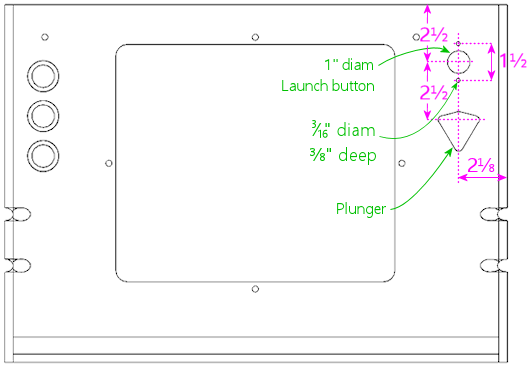

The front wall is the most complex section of the cabinet. It has a

whole bunch of things attached: the coin door, several pushbuttons,

the plunger, the lockbar, and the leg bolts. There are so many things

vying for a limited amount of space that the positioning of each part

is pretty constrained; everything fits together like a 3D puzzle.

I initially tried to cram all of the measurements for all of the

cutouts into a single diagram, but I quickly abandoned that idea,

since it was way too busy. So instead, I've broken it out into

several diagrams, one for each set of cutouts. We'll start with the

basic outline and its overall dimensions, with the purpose of each

cutout labeled.

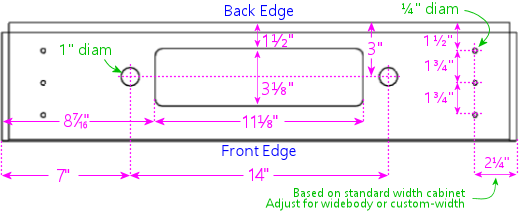

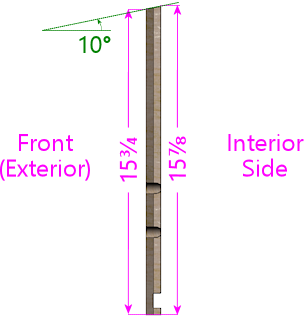

Main cabinet front panel, viewed from the front (exterior side).

Remember that we're measuring the dimensions based on a mitered

rabbet join at the corners, and that you might need to adjust the

dimensions slightly if you're using a different join style.

See

Joinery above.

More views for visualization:

The overall width is based on the standard-body design. If you're

building a widebody or custom-width cabinet, adjust the width of this

piece accordingly. Keep the coin door cutout centered horizontally at

the new width, and keep the buttons and plunger at the same distance